We recognize that maintaining peak performance in hydraulic systems requires strict adherence to international guidelines. These specifications ensure that every component meets rigorous safety and durability benchmarks. When you follow these technical frameworks, you guarantee that your equipment operates reliably under extreme pressure and within the most demanding environmental conditions.

The integration of these global benchmarks helps us streamline manufacturing processes and improve product interchangeability. By focusing on standardized dimensions and pressure ratings, we reduce the risk of catastrophic failure in your machinery. You can trust that equipment built to these specific requirements will deliver consistent results across various industrial applications.

What is ISO Standard?

An ISO standard is an internationally recognized set of rules developed by the International Organization for Standardization.

These guidelines provide technical specifications to ensure that products and services are safe, reliable, and consistent across global borders.

In hydraulics, these standards define everything from pressure ratings to testing methods, helping us maintain a universal language of safety.

We use these benchmarks to guarantee that the components you install in your machinery will function correctly, regardless of where they were manufactured. By following these established protocols, you reduce operational risks and improve the efficiency of your equipment. These standards act as a vital framework for engineers and manufacturers to deliver dependable results in every industrial application.

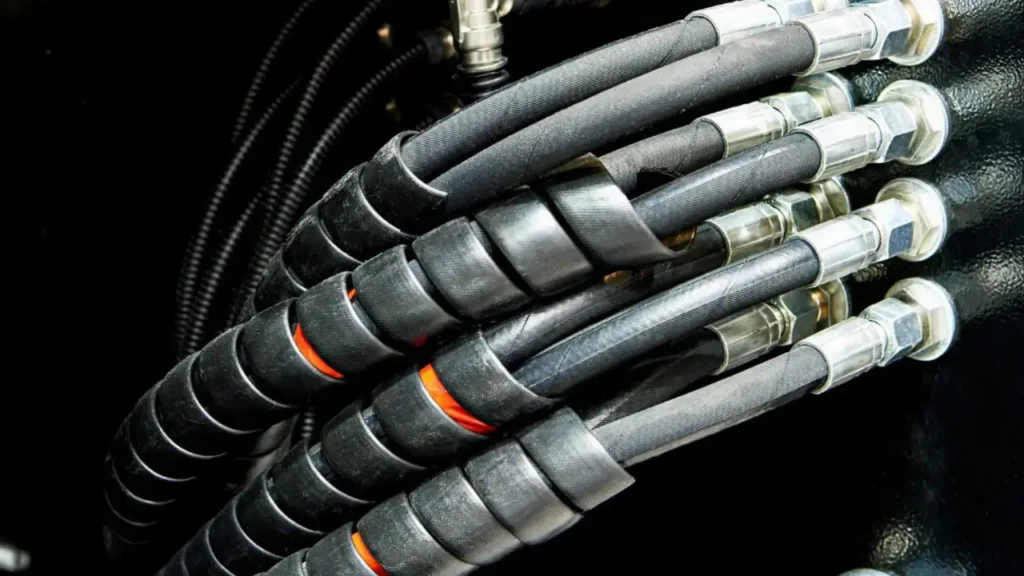

ISO Standard for Hydraulic Hoses

Hydraulic hoses are critical components in fluid power systems, ensuring safe and efficient transmission of hydraulic energy. ISO standards provide uniform specifications for hose design, performance, and testing. These standards help manufacturers maintain quality, ensure compatibility, and guarantee safety across different applications.

- ISO 1436 – Rubber hoses and hose assemblies: Specifies requirements for hydraulic rubber hoses, including construction, dimensions, and performance tests. Ensures hoses can withstand high-pressure operations while maintaining flexibility and durability in various environments.

- ISO 18752 – Thermoplastic hoses: Covers specifications for thermoplastic hydraulic hoses, detailing construction, pressure ratings, and temperature tolerances. Ensures consistent performance and reliability, particularly in automotive and industrial applications.

- ISO 6805 – Hose fittings and assemblies: Defines requirements for end fittings, couplings, and assembly procedures. Guarantees secure connections and reduces the risk of leaks or system failure.

- ISO 17123 – Testing procedures: Provides standardized methods for testing hose burst pressure, bending, and fatigue resistance. Assures that hydraulic hoses meet operational safety and longevity expectations.

How to Choose ISO Hydraulic Hoses?

Selecting the right ISO hydraulic hose is essential for system safety, efficiency, and longevity. Proper hose selection considers pressure requirements, fluid compatibility, temperature range, and mechanical stresses. Following ISO standards ensures reliable performance, reduces system failures, and maintains operational safety across industrial and mobile applications.

- Determine pressure requirements: Choose hoses rated for the system’s maximum working pressure. ISO standards classify hoses based on pressure ratings, ensuring safety and preventing burst failures. Correct pressure selection improves reliability and extends hose lifespan.

- Check fluid compatibility: Ensure the hose material is compatible with the hydraulic fluid used. ISO specifications guide material selection to resist chemical degradation, swelling, or leakage, maintaining consistent performance and avoiding costly system damage.

- Consider temperature range: Select hoses that tolerate the system’s minimum and maximum operating temperatures. ISO standards provide temperature ratings for hose materials, ensuring flexibility in cold conditions and durability under heat exposure.

- Evaluate mechanical stresses: Account for bending radius, vibration, and abrasion in the installation environment. ISO-compliant hoses are designed to withstand mechanical forces, reducing wear, preventing leaks, and maintaining long-term operational integrity.

- Select proper fittings: Choose fittings compatible with hose type and ISO standards. Proper connections prevent leaks, ensure secure assembly, and maintain system efficiency under high-pressure hydraulic conditions.

How to Check Hydraulic Hose Quality?

Ensuring hydraulic hose quality is crucial for safe and efficient operation of hydraulic systems. High-quality hoses resist pressure, temperature fluctuations, and mechanical stress. Following standardized inspection methods and ISO specifications helps identify defects, prevent failures, and prolong hose service life.

- Inspect hose material: Check for cracks, bubbles, or uneven surfaces. ISO-compliant hoses use durable rubber or thermoplastic materials that resist abrasion, chemical attack, and pressure, ensuring long-term reliability and safe hydraulic system operation.

- Check pressure rating: Verify the hose is rated for your system’s maximum working pressure. Properly rated hoses prevent burst failures, leaks, and downtime, maintaining efficiency and safety under demanding hydraulic conditions.

- Examine fittings and assemblies: Ensure end fittings are secure, correctly installed, and compatible with hose type. ISO standards guarantee proper fitting dimensions, reducing the risk of leaks, disconnections, and system malfunctions.

- Test flexibility and bending: Evaluate hose flexibility and minimum bend radius. Quality hoses maintain performance under repeated bending, vibration, and mechanical stress without kinking, cracking, or performance degradation.

- Review certifications and standards: Look for ISO compliance and manufacturer testing records. Certified hoses meet standardized performance, safety, and durability requirements, ensuring consistent quality and reliability in hydraulic applications.

Why Choose Our Hydraulic Hoses?

Choosing the right hydraulic hoses is vital for safe, efficient, and long-lasting hydraulic systems. Our hoses meet strict ISO standards, offering durability, reliability, and superior performance. Designed for diverse industrial and mobile applications, they minimize downtime and ensure consistent fluid power delivery.

- ISO-compliant quality: Our hoses adhere to international ISO standards, ensuring consistent performance, pressure ratings, and safety. This guarantees reliability in demanding hydraulic systems and reduces the risk of leaks, bursts, or operational failures.

- Durable materials: Made from premium rubber or thermoplastic compounds, our hoses resist abrasion, chemical corrosion, and extreme temperatures. High-quality materials extend service life, maintain flexibility, and ensure stable performance in diverse environments.

- Reliable fittings and assemblies: Equipped with secure, ISO-standard fittings, our hoses ensure leak-free connections. Properly assembled hoses reduce downtime, enhance safety, and provide consistent fluid flow for hydraulic equipment.

- Versatile applications: Suitable for industrial machinery, construction equipment, and mobile hydraulics, our hoses handle various pressures, temperatures, and mechanical stresses. They provide dependable performance across multiple environments.

- Tested for performance: Each hose undergoes rigorous pressure, bending, and durability tests. This ensures our hydraulic hoses consistently meet or exceed operational requirements, providing safety, efficiency, and long-term reliability.

Final Thoughts

We hope this overview helps you understand how critical technical compliance is for your daily operations. By implementing these standards, you protect your investment and ensure the safety of your workforce. We encourage you to review your current systems to verify that every hose assembly aligns with the latest performance criteria.

If you are looking to upgrade your inventory with premium components, you can find excellent options in our catalog. We provide a wide range of products designed to meet the most strenuous industrial demands. You can get wholesale hydraulic hoses from our Gushan rubber to ensure your projects benefit from superior craftsmanship.

Our team remains dedicated to supporting your growth by delivering products that exceed standard expectations. We invite you to contact us for customized solutions that fit your unique hydraulic requirements. By choosing our Gushan rubber for your bulk needs, you secure a partnership focused on efficiency and long-term industrial success.