When we talk about the incredible strength and toughness of hydraulic hose, we’re talking about its braid. This isn’t just a decorative outer layer; it’s the most critical component that gives the hose its ability to withstand tremendous pressure. Without it, a hydraulic hose is nothing more than a fragile rubber tube, completely unable to withstand the forces required to operate heavy machinery.

In this guide, we’ll explain in detail what the braid is, how it works, and why it’s a defining feature of a reliable hydraulic hose.

The Anatomy of a Hydraulic Hose

To understand the braid, we first need to look at the hose as a whole. A hydraulic hose is a multi-layered component, with each part serving a distinct purpose. From the inside out, there’s the inner tube, the reinforcement layer (the braid), and the outer cover. We often use the analogy of a pressure cooker; the inner tube contains the pressure, the braid holds it all together, and the outer cover protects the entire assembly from the environment. The synergy of these layers is what makes a hydraulic hose so effective and safe.

| Layer | Primary Function | Typical Material |

| Inner Tube | To carry the hydraulic fluid. | Synthetic rubber, thermoplastic, PTFE |

| Reinforcement (Braid) | To provide strength and resist pressure. | Steel wire, textile yarn, aramid fiber |

| Outer Cover | To protect the reinforcement and inner tube from damage. | Rubber, polyurethane, synthetic compounds |

What Is Braid For Hydraulic Hose

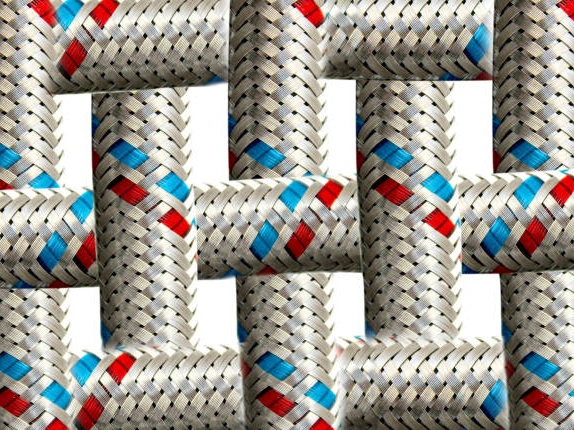

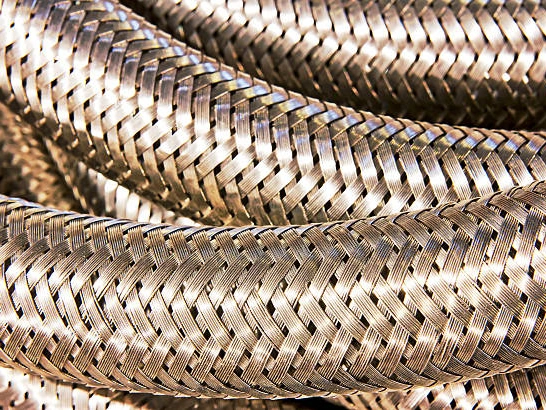

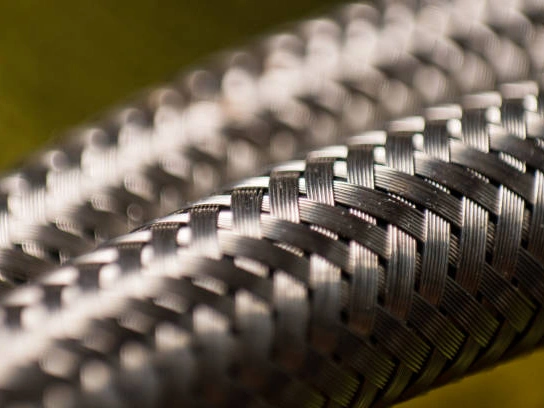

It is the woven layer of reinforcement located between the inner tube and the outer cover. This braid is typically made from high-tensile steel wire, though we also see it made from strong synthetic fibers. The individual strands of wire are wound around the hose core in a tight, crisscrossing pattern. This weaving is what provides the hose with its incredible burst pressure rating and prevents it from expanding under the intense pressure of hydraulic fluid. The angle of the weave is precisely calculated to maximize its strength.

We often explain to our clients that the braid isn’t just passive; it actively resists the outward force exerted by the pressurized fluid. The pressure pushes on the inner tube, and the inner tube pushes on the braid. The tension in the braid’s woven structure counters this force, keeping the hose’s shape and integrity. It is this mechanical action that allows a hydraulic hose to handle the thousands of pounds per square inch of pressure required in hydraulic systems.

Understanding Different Types of Hydraulic Hose Braid

The type of braid used is a key factor in a hydraulic hose’s performance and is one of the first things we consider when recommending a product to a customer. We supply hoses with different braid configurations to meet a wide range of needs.

Single-Braided Hose

A single-braid hose features one layer of woven wire or fiber reinforcement. We recommend this type for medium-pressure applications where flexibility is also a concern. It provides excellent pressure resistance while remaining relatively lightweight and easy to route in tight spaces. We see single-braided hoses used frequently in agricultural machinery and general-purpose industrial equipment.

Double-Braided Hose

When our customers need more power, we turn to a double-braided hose. This hose has two layers of interwoven wire reinforcement, separated by a thin rubber layer. The extra layer of braid significantly increases the hose’s burst pressure rating, making it suitable for high-pressure hydraulic systems. This is the workhorse of heavy construction equipment and mining machinery.

Spiral-Wrapped Hose

For the most extreme, high-pressure applications, we use spiral-wrapped hose, which technically isn’t a braid. Instead of being woven, the reinforcement is made of multiple layers of steel wire spiraled in alternating directions. This construction provides exceptional strength and resistance to flex fatigue. We supply spiral-wrapped hose for ultra-high-pressure applications like in demolition equipment and large cranes.

How Braid Affects Hydraulic Hose Performance

The braid is the single most important factor determining a hydraulic hose’s performance characteristics. We break down its impact into a few key areas.

- Pressure Rating: The number of braids directly correlates to the hose’s pressure rating. More layers of braid mean a higher working and burst pressure. This is a non-negotiable factor for us when helping a customer select a hose for a specific application.

- Flexibility: Generally, more braids lead to a less flexible hose. A single-braid hose is more pliable than a double-braid hose. We always balance the pressure needs with the application’s routing and flexibility requirements.

- Weight: More braid layers also increase the hose’s weight. This can be a concern for mobile or aerospace applications, which is why we sometimes recommend hoses with aramid fiber braid, which provides excellent strength with less weight.

- Service Life: The braid’s ability to resist pressure fatigue and abrasion significantly extends the service life of the hose. A braided hydraulic hose is a long-term investment in reliability and safety.

Are Steel Braided Hoses Better?

In most cases, steel braided hoses are significantly better than standard rubber or plastic hoses, especially for high-pressure or critical applications. The woven stainless steel layer acts as a reinforcement, providing exceptional durability and strength. This prevents the hose from expanding under pressure, which is a common cause of failure in unreinforced hoses.

The steel braid also protects the inner tube from external damage, such as cuts and abrasion, making it much more reliable and longer-lasting. While they may be less flexible and more expensive, the enhanced safety and longevity they provide make them the superior choice for high-demand jobs.

Does Braided Hose Kink?

While braided hoses are more kink-resistant than standard hoses, they can still kink if bent beyond their minimum bend radius. Their sturdy braid is designed to prevent kinking during normal use, ensuring consistent flow.

Even if the outer braid doesn’t show visible creases, forcing the hose into an excessively tight bend can still cause the inner tube to collapse and restrict flow. We always recommend using a hose of the correct length and allowing ample slack to avoid excessive bending. This helps maintain the hose’s integrity and prevents premature failure.

Conclusion

Modern machinery simply wouldn’t function without this carefully engineered braid or spiral. It’s the braid that makes hydraulic hoses braided hoses, and it’s what makes them reliable and safe components capable of handling some of the toughest jobs on the planet. If you’d like to learn more about our hoses, check out our website.