Hydraulic hose compatibility isn’t just a technical detail; it’s the foundation of a safe, efficient, and reliable hydraulic system. When a hose, fitting, or fluid doesn’t match the system’s requirements, the consequences can be severe, from premature hose failure and costly downtime to dangerous fluid leaks and potential injuries.

Understanding the science behind hose compatibility is essential for anyone who operates, maintains, or designs hydraulic equipment.

What is Hydraulic Hose Compatibility?

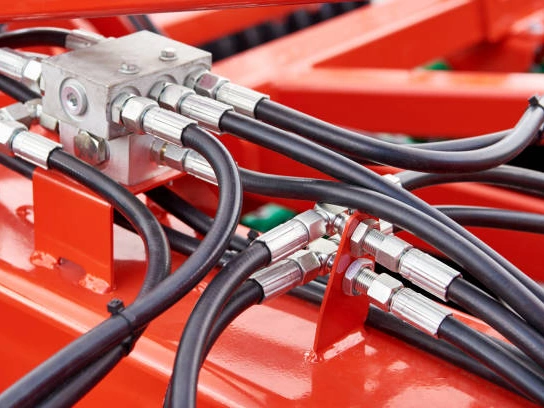

Hydraulic hose compatibility refers to the ability of all components—the hose, the fluid, and the fittings—to work together seamlessly without degrading or failing.

It’s a complex relationship where each part must be matched to the others. A hose might be rated for a certain pressure, but if the fluid inside is chemically incompatible with the hose’s inner tube material, it will break down from the inside out, leading to catastrophic failure.

The core of compatibility revolves around three key factors:

- Fluid Compatibility: The hose’s inner tube and outer cover must be compatible with the fluid it transports. Different hydraulic fluids (e.g., mineral oil, synthetic fluids, fire-resistant fluids) have different chemical compositions that can react with the hose material.

- Pressure and Temperature Ratings: The hose must be rated to handle the maximum operating pressure and temperature of the system. Exceeding these ratings can cause the hose to burst or degrade quickly.

- Size and Fittings: The hose’s inner diameter (ID), outer diameter (OD), and the fittings must all match perfectly. An improperly sized hose or mismatched fittings can cause leaks, blow-offs, and other failures.

Hydraulic Hose Chemical Compatibility

The most common cause of hydraulic hose failure we’ve encountered is a breakdown in chemical compatibility. This is the relationship between the fluid inside the hose and the hose’s inner tube material. The hydraulic fluid, whether it’s a mineral oil, a synthetic fluid, or a fire-resistant type, has a unique chemical makeup.

If the hose material isn’t designed to resist that specific fluid, it can swell, harden, soften, or otherwise deteriorate. This compromises the hose’s structural integrity, making it a ticking time bomb.

A simple yet critical step we always take is to consult a fluid compatibility chart. These charts, provided by hose manufacturers, are an invaluable resource. They typically list various hose materials and indicate their compatibility with different types of fluids.

Common Hose Materials and Their Compatibility

| Hose Inner Tube Material | Common Compatible Fluids | Common Incompatible Fluids |

| Nitrile (NBR) | Petroleum-based oils, air, and gasoline | Fire-resistant fluids (HFC, HFD), brake fluids |

| Neoprene (CR) | Petroleum-based oils, some phosphate esters | Ketones, aromatic hydrocarbons |

| EPDM | Phosphate ester fluids, brake fluids, and hot water | Petroleum-based oils, synthetic fluids |

| PTFE (Teflon) | A wide range of aggressive chemicals, high-temperature fluids | None, PTFE is nearly universally chemically iner |

It’s important to remember that using a hose with an incompatible fluid can lead to more than just leaks. It can cause the hose material to break down into small particles, which can contaminate the hydraulic system, clog filters, and damage expensive pumps and valves.

Hydraulic Hose Fluid Compatibility

While we’ve touched on this, it’s worth diving deeper into the nuances of hydraulic hose fluid compatibility. The fluid is the lifeblood of the hydraulic system, and its properties dictate a great deal about the hose you should use. It’s not just about the chemical composition; factors like temperature and viscosity also play a role in hydraulic hose compatibility.

- Temperature: The fluid’s operating temperature can affect the hose material. High temperatures can accelerate chemical reactions and cause certain materials to become brittle. Always ensure the hose’s temperature rating meets or exceeds the maximum operating temperature of the fluid.

- Viscosity: The fluid’s viscosity, or thickness, can impact flow and pressure within the system. A hose with too small an inner diameter for a high-viscosity fluid can cause excessive heat generation and pressure drops.

We often remind people that using a “one-size-fits-all” approach to hoses is dangerous. For instance, a fire-resistant fluid, designed for safety in high-heat environments, requires a special hose that won’t be degraded by its unique chemical makeup. Using a standard petroleum-rated hose with such a fluid is a recipe for disaster.

How to Choose Compatible Hydraulic Hoses?

Choosing the right hose is a systematic process. Over the years, we’ve developed a simple checklist to ensure we’ve covered all our bases. This approach helps us guarantee hydraulic hose compatibility and avoid costly, and potentially dangerous, mistakes.

A Checklist for Hydraulic Hose Selection

- Identify the Fluid: What type of hydraulic fluid is your system using? Check the equipment manual or the fluid container itself.

- Determine the Pressure: What is the maximum operating pressure of the system, including any potential pressure spikes? The hose’s working pressure rating must be higher than this value.

- Check the Temperature: What are the minimum and maximum fluid and ambient temperatures? The hose’s temperature rating must accommodate this range.

- Measure the Inner Diameter (ID): What is the required inner diameter of the hose to ensure proper flow? Refer to the manufacturer’s flow rate charts to select the correct size.

- Examine the Operating Environment: Will the hose be exposed to abrasion, UV light, ozone, or chemicals? Choose a hose with a cover material that can withstand these conditions.

- Match the Fittings: What type of end fittings are required for the connection points on your equipment? Ensure the thread type and size are an exact match for both the hose and the machine’s ports.

We can’t stress enough the importance of following the manufacturer’s recommendations. They’ve tested their products for specific applications, and straying from their guidelines is a gamble you don’t want to take.

How to Know if a Hydraulic Hose is Compatible?

You might be faced with an existing system and need to verify the hoses are compatible. We’ve been in this situation many times, and there are several ways to check. This process is crucial for maintenance and for anyone acquiring new or used equipment.

- Read the Hose Layline: Most hoses have a layline—a printed line running along the length of the hose. This line contains vital information, including the manufacturer’s name, the hose series number, its size, and pressure rating. You can use this information to look up the hose’s specifications on the manufacturer’s website and check for compatibility.

- Inspect for Signs of Degradation: Look for visual clues. An incompatible hose may show signs like swelling, cracking, hardening, or a sticky feel. These are clear indicators that the hose material is breaking down due to a chemical reaction with the fluid.

- Check the Fittings: Ensure the fittings are the correct type for the hose and are properly crimped. A loose or incorrect fitting is a major compatibility issue that can lead to leaks or a blow-off.

- Test the System: After a visual inspection, a gradual test of the system under low pressure can help you spot minor leaks before they become major problems.

If you have any doubts about a hose’s compatibility, it’s always safer to replace it with a new one that you know is correctly rated for the application. The cost of a new hose is minimal compared to the potential costs of a system failure.

Can You Mix Different Hydraulic Fluids Together?

Mixing different hydraulic fluids is generally not recommended and can be dangerous. While some fluids may appear similar, they often have different base oils and unique additive packages. Mixing them can lead to a chemical reaction, causing the additives to clash and lose their effectiveness. This can result in:

- Sludge or deposit formation, which clogs filters and lines.

- Reduced lubrication, leading to increased friction and wear on components.

- Corrosion and seal damage.

- Increased foaming, which impairs system performance and can cause cavitation.

Always consult the manufacturer’s recommendations and use a single, approved fluid to maintain system integrity and safety.

Conclusion

Ultimately, hydraulic hose compatibility is an integral aspect of safety and performance in any hydraulic application. It involves a complex interplay of chemical, temperature, and pressure requirements, all of which must be perfectly matched.

By understanding the principles of chemical and fluid compatibility and adopting a systematic approach to hose selection, you can avoid dangerous failures, extend equipment life, and ensure your system operates at optimal efficiency. As professionals, we understand that taking the time to verify each component is the best investment you can make. Always check the run lines, consult the manufacturer’s diagrams, and if in doubt, replace immediately.