There’s a significant difference between braided and non-braided hoses. When choosing a hose, it’s easy to focus on size and material, but it’s the internal structure that truly determines its performance and safety. Non-braided hoses may superficially resemble braided hoses, but their functions are vastly different. Choosing the wrong type of hose can lead to costly failures. In this guide, we’ll uncover the key differences and help you understand why this choice is so important.

What’s the Hose Construction?

Think of a flexible hose as the artery of a fluid system. Just as an artery needs strong walls to handle blood pressure, a hose needs robust construction to safely transfer fluids under pressure. The presence or absence of a braided reinforcement is the single most important factor that dictates a hose’s strength, durability, and a host of other critical characteristics. We believe that understanding this core principle is the foundation for making a smart, safe, and lasting investment in any fluid transfer system, from your home workshop to a professional industrial setup.

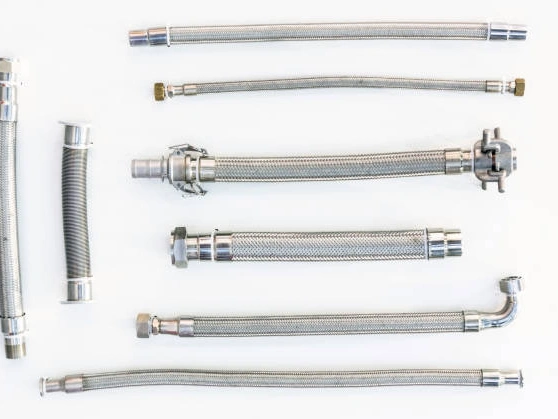

What Are Braided Hoses?

Braided hoses are high-performance fluid transfer lines distinguished by their unique reinforcement. They consist of an inner core, typically made from materials like PTFE or synthetic rubber, which is then covered by a woven layer of high-tensile material, most commonly stainless steel. This braid acts as a structural skeleton, providing immense strength and durability. It prevents the hose from expanding under high pressure, resists kinking, and protects the inner tube from external abrasion and damage. The result is a hose with superior pressure ratings and a longer lifespan, making it the top choice for demanding applications in automotive, industrial, and hydraulic systems.

What’s the Unbraided Flexible Hose

Unbraided flexible hoses are inherently simple. They’re typically constructed from a single layer of material, such as PVC, rubber, or silicone. This simplicity is their greatest strength—they’re extremely flexible, lightweight, and easy to handle. We favor them for simple tasks involving low pressure. Because they lack additional reinforcement, these hoses are often more affordable and can be easily bent into tight radii. They’re ideal for applications like garden hoses and low-pressure drain lines.

| Unbraided Flexible Hose | |

| Why It Works: | Where It Falls Short: |

| * Highly flexible and lightweight | * Very low pressure rating |

| * Excellent for tight spaces | * Prone to kinking and collapsing |

| * Cost-effective and widely available | * Minimal durability against abrasion |

| * Great for non-critical, low-pressure uses | * Limited resistance to burst pressure |

Why Is Braiding a Game-Changer?

The braided flexible hose is an entirely different beast. Its core design principle is reinforcement. A woven layer, or “braid,” made of synthetic fibers or stainless steel is integrated between the inner and outer layers of the hose. This braid acts as a shield, providing immense structural integrity. This single feature transforms a simple hose into a high-performance component. The braid prevents the hose from expanding under high pressure, makes it highly resistant to kinking, and protects it from external abrasion. When we need a hose for serious work, we always look for a braided one.

Difference Between Braided and Unbraided Flexible Hose

The most significant difference between a braided and unbraided flexible hose is its ability to handle pressure. An unbraided hose simply cannot withstand significant internal force. The braid on a hose distributes pressure evenly around the circumference, preventing ballooning and bursting. For applications like hydraulics, fuel injection, or compressed air systems, this is a non-negotiable feature. Without a braid, the hose would fail almost instantly.

- Pressure Performance: We’ve tested countless hoses, and the data is clear: braided hoses can handle pressures that would obliterate an unbraided one. Their reinforcement ensures they maintain their shape and integrity, even under extreme conditions.

- Durability in Harsh Environments: A braided hose is built to last. The external braid provides a crucial layer of protection against rubbing, cuts, and punctures. We’ve used them in dirty, high-vibration engine bays and on heavy machinery where unbraided hoses would be shredded in no time.

- Flow Consistency: Kinking is the enemy of consistent flow. An unbraided hose can easily kink, completely shutting off the flow of fluid and potentially causing a dangerous pressure buildup. The braided structure prevents kinking, ensuring a steady, reliable flow at all times.

- Torsion Resistance: Twisting and turning forces are common in dynamic systems. The braided hose is engineered to resist these torsional stresses, preventing the hose from unwinding or fatiguing at the connection points.

How to Choose the Right Hose?

When Is an Unbraided Hose the Right Choice?

Despite the clear advantages of braiding, an unbraided flexible hose still has its place. We recommend them when the primary requirements are cost-effectiveness and extreme flexibility, and when pressure is not a concern. For example, in a home aquarium setup, a simple, unbraided silicone hose is perfect for air lines. Similarly, for a simple drain line under a sink, there’s no need for the added expense and stiffness of a braided hose. In these situations, the simple design is not a weakness but a strength.

When Should You Always Choose Braiding?

We consider a braided hose mandatory for any of the following applications:

- High-Pressure Hydraulic Systems: The sheer force in these systems demands the burst resistance of a braided hose.

- Performance Automotive Applications: Fuel, oil, and brake lines need to withstand high pressure, temperature, and exposure to corrosive fluids. A stainless steel braided hose is the industry standard for this.

- Industrial Fluid Transfer: For transporting chemicals, steam, or high-pressure water, the durability and safety of a braided hose are non-negotiable.

- Critical Water Supply Lines: In situations like a water softener or reverse osmosis system, the pressure and continuous use warrant a braided connection to prevent leaks and flooding.

Can We Have the Best of Both Worlds?

Absolutely! The fluid transfer industry has evolved to meet complex needs. We often recommend hybrid solutions that offer the best of both worlds. For instance, a CPE braided hose combines the excellent chemical resistance and flexibility of a CPE inner liner with a robust stainless steel braid. This gives you a hose that is both incredibly durable and highly adaptable, perfect for performance fuel systems where you need both high pressure handling and resistance to modern fuels. It’s a solution we see more and more, and for good reason.

Conclusion

Choosing between braided and unbraided flexible hose isn’t complicated. It all depends on the primary application of your hose. For high-pressure, high-stress, or mission-critical applications, the answer is always braided hose. For low-pressure, simple, and non-critical applications, the flexibility and cost-effectiveness of non-braided hoses are the perfect solution. Consider pressure, durability, and safety to make the right choice.

If you’re unsure about your choice, contact us for professional advice.