High-pressure hydraulic systems demand meticulous attention to component specifications, especially hydraulic hose maximum pressure. Exceeding these limits risks catastrophic failure, leading to equipment damage and potential injury. This blog explores the crucial considerations for selecting and maintaining hoses in such demanding environments.

We’ll delve into factors influencing maximum pressure ratings, including hose construction, material composition, and operating temperatures. Understanding these elements is vital for ensuring system integrity and longevity. We’ll also cover best practices for inspection, maintenance, and safe operation within high-pressure hydraulic applications.

Hydraulic Hose Maximum Pressure

Hydraulic hose maximum pressure is a critical specification that defines the upper limit of pressure a hydraulic hose can safely withstand during operation. Exceeding this limit can lead to catastrophic failures, resulting in property damage, injuries, or even fatalities. Understanding the factors that influence maximum pressure, such as hose construction, material, and operating temperature, is crucial for selecting the appropriate hose for a given application. Proper selection ensures system reliability and personnel safety.

The maximum working pressure (MWP) is the most common pressure rating, indicating the highest pressure the hose is designed to handle continuously. Burst pressure, on the other hand, is the pressure at which the hose is expected to rupture. It’s significantly higher than the MWP and serves as a safety threshold. Selecting a hose with an MWP that exceeds the system’s operating pressure, with a safety margin, is essential for safe operation. Additionally, pressure spikes and surges within the hydraulic system must be considered when determining the appropriate MWP.

Regular inspections and preventative maintenance are essential for maintaining the integrity of hydraulic hoses. Factors like abrasion, corrosion, and fluid compatibility can degrade the hose over time, reducing its maximum pressure capacity. Implementing a scheduled maintenance program, including visual inspections and periodic pressure testing, helps identify potential issues before they lead to failures. Correct installation and routing of hoses are crucial to prevent kinking, twisting, and excessive bending, all of which can negatively impact the hose’s pressure rating.

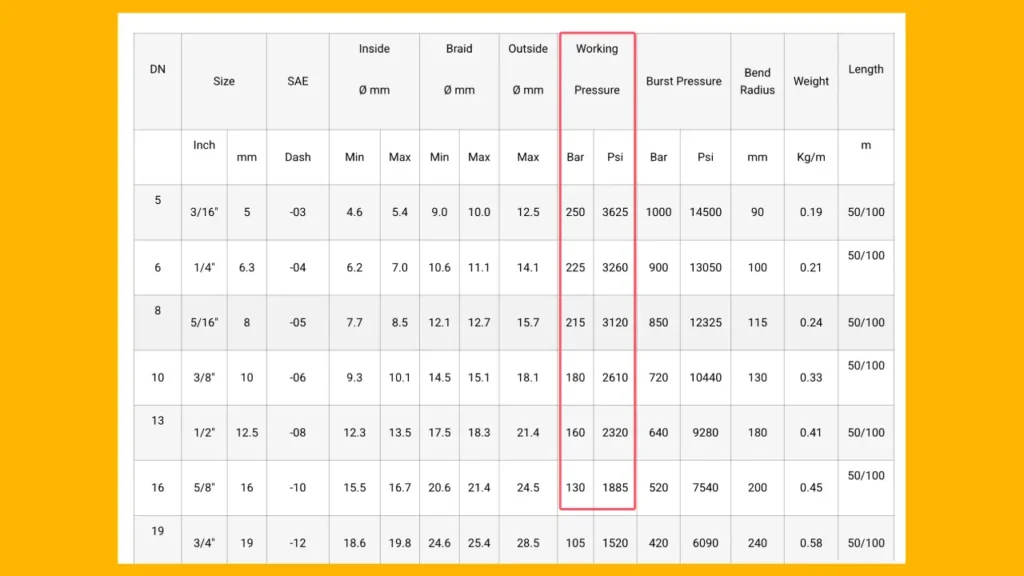

Hydraulic Hose Maximum Pressure Chart (Example):

| Hose Type (SAE Standard) | Maximum Working Pressure (PSI) | Burst Pressure (PSI) | Typical Application |

| SAE 100R1 | 2,250 | 9,000 | Medium-pressure hydraulics, general purpose |

| SAE 100R2 | 4,000 | 16,000 | High-pressure hydraulics, heavy equipment |

| SAE 100R7 | 3,000 | 12,000 | Thermoplastic, medium-pressure, tight bend radius |

| SAE 100R12 | 5,000 | 20,000 | Very high-pressure, severe applications |

| SAE 100R13 | 6,000 | 24,000 | Extreme high-pressure, demanding environments |

Hydraulic Hose Pressure Testing Standards

Hydraulic hose pressure testing standards are crucial for ensuring the safety and reliability of hydraulic systems. These standards outline specific procedures and requirements for testing hydraulic hoses to verify their ability to withstand the pressures and conditions they will encounter in operation. Some of the most common standards include:

- ISO 11237: This international standard provides comprehensive guidelines for hydraulic fluid power hose assemblies, covering design, construction, testing, and marking requirements.

- SAE J517: This Society of Automotive Engineers standard focuses on rubber-covered, steel wire-reinforced hydraulic hoses, specifying performance criteria and test methods.

- EN 853: This European standard outlines requirements for rubber hoses used in general fluid power systems, including hydraulic applications.

Adherence to these standards helps ensure that hydraulic hoses can safely handle the pressures they are designed for, reducing the risk of failures, leaks, and potential hazards.

| Standard | Description |

| ISO 11237 | Specifies requirements for hydraulic fluid power hose assemblies. Covers design, construction, testing, and marking. |

| SAE J517 | Covers requirements for rubber covered steel wire reinforced hydraulic hose. |

| EN 853 | Specifies requirements for rubber hoses for general use in fluid power systems. |

| DIN 20022 | German standard for rubber hoses for hydraulic fluid power. |

| JIS B 8333 | Japanese Industrial Standard for rubber hoses for hydraulic fluid power. |

Hydraulic Hose Pressure Test Procedure

Hydraulic hose pressure testing is essential for verifying the integrity and safety of hydraulic hoses. It involves subjecting the hose to specified pressures to ensure it can withstand the intended operating conditions. Here’s a step-by-step guide:

Step 1: Preparation and Safety Checks

Before testing, thoroughly inspect the hose for any visible damage, such as cuts, abrasions, or kinks. Ensure the hose is clean and free from debris. Verify that the testing equipment, including the pressure gauge and pump, is calibrated and in good working order. Safety is paramount; wear appropriate personal protective equipment (PPE), including safety glasses and gloves. Ensure the test area is clear of personnel and potential hazards.

Additionally, double-check the hose’s specifications, including its maximum working pressure and burst pressure. This information is crucial for setting the test parameters. Ensure the fluid used for testing is compatible with the hose material and the operating conditions. Select a suitable test bench or fixture that can securely hold the hose and prevent movement during the test.

Step 2: Connecting the Hose and Filling with Fluid

Connect the hydraulic hose to the pressure test equipment, ensuring a secure and leak-free connection. Use appropriate adapters and fittings to prevent damage to the hose ends. Slowly fill the hose with the test fluid, ensuring all air is purged from the system. Air pockets can cause inaccurate pressure readings and potentially dangerous pressure spikes.

Once the hose is filled and air is removed, close all valves and connections. Gradually increase the pressure to a low level to check for leaks at the connections. If any leaks are detected, tighten the connections or replace the faulty components. Ensure the hose is straight and not twisted or bent during the filling process.

Step 3: Applying and Holding the Test Pressure

Gradually increase the pressure to the specified test pressure, which is typically a percentage of the hose’s burst pressure, as determined by the relevant standards. Hold the pressure for a specified duration, usually a few minutes, to allow for thorough testing. Monitor the pressure gauge closely for any pressure drops, which could indicate a leak or hose failure.

During the hold period, inspect the hose for any signs of swelling, deformation, or leakage. Carefully observe the hose’s behavior under pressure. Any unusual sounds or vibrations should be noted and investigated. After the hold period, slowly release the pressure, ensuring a controlled and gradual decrease.

Step 4: Inspection and Documentation

After releasing the pressure, carefully inspect the hose for any permanent deformation, cracks, or other signs of damage. Check the connections for leaks and ensure they are still secure. If the hose passes the test, record the test results, including the test pressure, duration, and any observations. Document the test procedure, including the equipment used and the date of the test.

If the hose fails the test, document the failure mode, including the location and type of damage. Discard the failed hose according to safety regulations. Maintain accurate records of all tests, including passed and failed hoses. This documentation is essential for quality control and safety compliance.

Hydraulic Hose Pressure Rating

Hydraulic hose pressure rating is a critical specification that indicates the maximum pressure a hose can safely handle. This rating is determined by factors like the hose’s construction, materials, and intended application. Understanding these ratings is essential for preventing hose failures, leaks, and potential safety hazards. Key pressure ratings include:

- Maximum Working Pressure (MWP): The highest pressure the hose is designed to operate under continuously.

- Burst Pressure: The pressure at which the hose is expected to rupture.

- Proof Pressure: A pressure applied during testing to verify the hose’s integrity, typically higher than the MWP but lower than the burst pressure.

Selecting the right hydraulic hose pressure rating is crucial for ensuring the safety and efficiency of hydraulic systems. Overestimating or underestimating the required pressure can lead to premature hose failure or system malfunctions. Consider the operating pressure of the system, potential pressure spikes, and the environmental conditions when choosing a hose. Always consult the manufacturer’s specifications and relevant industry standards.

Proper installation, maintenance, and regular inspections are also essential for maintaining the integrity of hydraulic hoses. Factors such as temperature, fluid compatibility, and external abrasion can affect the hose’s pressure rating over time. Adhering to recommended operating procedures and implementing preventative maintenance measures can extend the lifespan of hydraulic hoses and minimize the risk of pressure-related failures.

Hydraulic Hose Pressure Rating Chart

Hydraulic hose pressure rating is a critical specification that indicates the maximum pressure a hose can safely handle. This rating is determined by factors like the hose’s construction, materials, and intended application. Understanding these ratings is essential for preventing hose failures, leaks, and potential safety hazards. Key pressure ratings include:

- Maximum Working Pressure (MWP): The highest pressure the hose is designed to operate under continuously.

- Burst Pressure: The pressure at which the hose is expected to rupture.

- Proof Pressure: A pressure applied during testing to verify the hose’s integrity, typically higher than the MWP but lower than the burst pressure.

Selecting the right hydraulic hose pressure rating is crucial for ensuring the safety and efficiency of hydraulic systems. Overestimating or underestimating the required pressure can lead to premature hose failure or system malfunctions. Consider the operating pressure of the system, potential pressure spikes, and the environmental conditions when choosing a hose. Always consult the manufacturer’s specifications and relevant industry standards.

Proper installation, maintenance, and regular inspections are also essential for maintaining the integrity of hydraulic hoses. Factors such as temperature, fluid compatibility, and external abrasion can affect the hose’s pressure rating over time. Adhering to recommended operating procedures and implementing preventative maintenance measures can extend the lifespan of hydraulic hoses and minimize the risk of pressure-related failures.

| Hose Type (Example) | Maximum Working Pressure (PSI) | Burst Pressure (PSI) | Application Example |

| SAE 100R1 | 2,250 | 9,000 | Medium-pressure hydraulics |

| SAE 100R2 | 4,000 | 16,000 | High-pressure hydraulics |

| SAE 100R7 | 3,000 | 12,000 | Medium-pressure thermoplastic hydraulics |

| SAE 100R12 | 5,000 | 20,000 | Very high-pressure hydraulics |

| SAE 100R13 | 6,000 | 24,000 | Extreme high-pressure hydraulics |

Important Note: This chart is a simplified example. Always refer to the specific manufacturer’s data sheets for accurate and up-to-date pressure ratings. Pressure ratings are also affected by hose size, temperature, and bend radius.

Conclusion

Understanding hydraulic hose maximum pressure is paramount in high-pressure systems to prevent catastrophic failures and ensure operator safety. Careful consideration of operating pressures, temperature, and fluid compatibility is crucial for selecting the right hose. Overlooking these factors can lead to premature wear, leaks, and potentially dangerous ruptures, impacting productivity and increasing costs. Prioritize safety and reliability by investing in quality hoses designed for your specific application.

Selecting the correct hydraulic hose maximum pressure is not just a technical detail; it’s a critical safety measure. Regular inspections and preventative maintenance further contribute to a safe and efficient hydraulic system. Don’t compromise on quality when dealing with high-pressure applications.

For reliable, high-pressure hydraulic hoses that meet your demanding needs, explore Gushan Rubber’s wholesale options. Contact us today to learn more and ensure your systems operate safely and efficiently.