When we talk about oxy-fuel welding and cutting, most of the attention goes to the torch and the regulators. However, one of the most vital—and often overlooked—components is the oxygen hose. This hose is the lifeline of your oxy-fuel system, delivering a steady supply of oxygen from the cylinder to the torch.

Without a dedicated and properly functioning oxygen hose, you simply cannot achieve the high temperatures required for cutting and welding. It’s a critical piece of equipment that warrants a deeper look, so we can better understand its purpose, composition, and why it plays such a crucial role in our safety and work quality.

What Is An Oxygen Hose?

An oxygen hose is a special type of tubing designed to safely transport oxygen. It’s used in medical settings to deliver oxygen to patients and in industrial applications like welding and cutting. These hoses are made from materials resistant to the corrosive and high-pressure properties of oxygen, often with a distinctive blue or green color for easy identification.

What is an Oxygen Hose Made of?

An oxygen hose is typically made from a combination of materials that can withstand high pressure and are compatible with oxygen, which is a highly reactive gas. These materials are chosen to prevent ignition and degradation, ensuring safety and durability. For instance, in medical settings, the tubing may be made from a polyethylene EVA copolymer or silicone, which are lightweight and flexible. Industrial oxygen hoses, which carry high-pressure gas for applications like welding, often have multiple layers to enhance strength and safety.

- Inner Core: The innermost tube is often made of PTFE (Teflon), rubber (like EPDM or NBR), or polyethylene. These materials are chosen for their resistance to chemical reactions with oxygen and their ability to maintain purity.

- Reinforcement: To handle high pressure, the core is reinforced with layers of textile or braided stainless steel. This braiding provides exceptional strength and prevents the hose from bursting under pressure.

- Outer Cover: The outermost layer is typically a durable, abrasion-resistant material like synthetic rubber or PVC, often colored blue or green to signify it’s for oxygen use. This cover protects the inner layers from external damage and environmental factors.

What is Oxygen Hose Used for?

An oxygen hose is primarily used for safely transporting oxygen from a source to the point of use. The specific application can vary widely, from medical to industrial settings, but the core function remains the same: to deliver oxygen in a controlled and reliable manner.

Industrial Uses

In industrial environments, oxygen hoses are crucial for a variety of tasks, particularly those involving high-pressure gas. They are a vital part of equipment used for:

- Welding and Cutting: Paired with a fuel gas hose (often red for acetylene), the oxygen hose (typically blue or green) supplies oxygen to a cutting torch or welding gun to create a high-temperature flame.

- Metal Production: In steel mills and other metalworking facilities, these hoses are used in processes like oxygen lancing, where a high-pressure jet of pure oxygen is used to melt through metal.

Medical Applications

In the medical field, oxygen hoses are a critical component of oxygen therapy for patients who have trouble breathing. They are used to:

- Deliver Oxygen to Patients: The hose connects an oxygen source, such as an oxygen concentrator or a compressed gas cylinder, to a patient’s delivery device like a nasal cannula or a face mask.

- Provide Mobility: Long oxygen hoses (up to 50 feet) allow patients to move around their homes while still receiving a continuous supply of oxygen from a stationary machine.

What Is the Standard Color of an Oxygen Hose

The standard color for an oxygen hose varies depending on the country or region and the specific application, but it is typically a shade of green, blue, or black. This color-coding is a critical safety measure used to prevent the accidental mixing of gases, which can lead to dangerous situations, particularly in welding and medical environments. While there are some differences, the main goal is to have a clear and consistent way to identify oxygen lines.

- Green: In the United States, medical and industrial oxygen hoses are often green. This color is widely recognized for oxygen and is part of the American Welding Society (AWS) and National Fire Protection Association (NFPA) standards for medical gas systems.

- Blue: Many European countries and some international standards designate blue for oxygen hoses. This is particularly common in industrial settings like welding and cutting, providing a clear contrast to red hoses used for flammable gases like acetylene.

- White: In some countries and for specific applications, especially in medical facilities, white is used to identify oxygen lines or components. This can be seen in some international standards for medical gas cylinders and piping.

What Is the Significance of Oxygen Hose Color Coding?

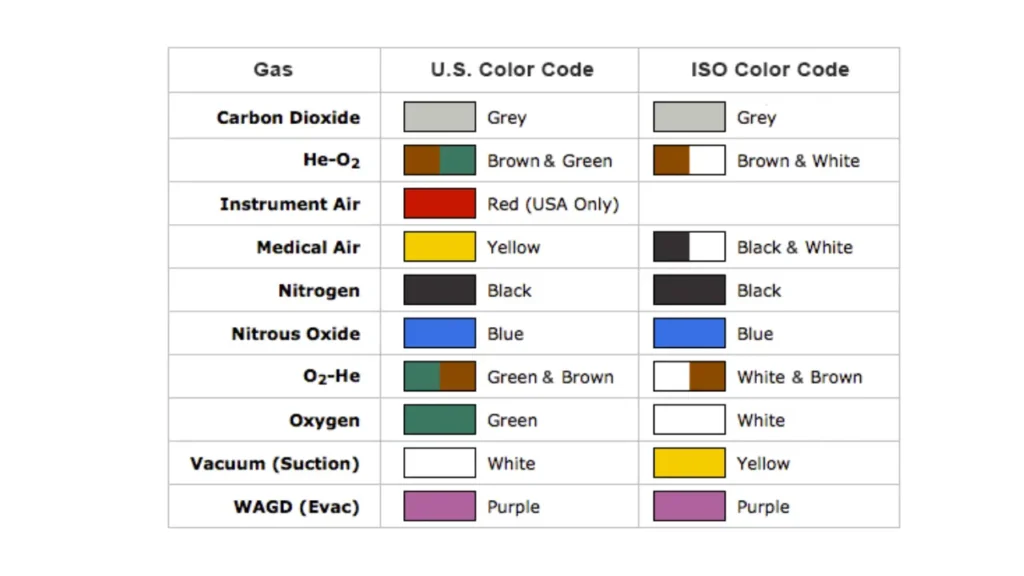

The color coding of welding hoses is a fundamental safety practice that has been standardized by organizations like the International Organization for Standardization (ISO) and the Compressed Gas Association (CGA).

This simple system helps prevent fatal accidents that could result from connecting the wrong hose to the wrong regulator. Imagine accidentally running a flammable fuel gas through an oxygen line—this could lead to a catastrophic explosion. The consistent use of green for oxygen and red for fuel gas eliminates this guesswork.

It’s an immediate, intuitive reminder of what gas is in each line, which is especially vital in busy or low-light work environments where a moment’s inattention could have devastating consequences.

| Hose Color | Gas Type | Standard |

| Green | Oxygen | Universal Standard |

| Black | Oxygen | North American Standard |

| Red | Fuel Gas (Acetylene, Propane, etc.) | Universal Standard |

| Blue | Inert Gas (Argon, Nitrogen) | Universal Standard |

What Materials Are Used to Make an Oxygen Hose?

An oxygen hose is engineered to be a robust and durable piece of equipment. It needs to withstand high internal pressures while remaining flexible enough for practical use. A typical oxygen hose is made from a few key layers. The inner tube, which comes into direct contact with the gas, is often a synthetic rubber compound like EPDM (Ethylene Propylene Diene Monomer) or SBR (Styrene Butadiene Rubber).

This material is chosen for its durability and chemical resistance to oxygen. The middle layer is a reinforcing braid, usually made of a high-tensile synthetic yarn or thread, which provides the strength needed to handle high pressures.

The outer cover is a protective layer of rubber that resists abrasion, cuts, and environmental factors like ozone and UV light.

How to Use an Oxygen Hose Safely?

Safe use of an oxygen hose is critical, as oxygen can accelerate combustion. Following proper procedures for setup, maintenance, and handling can prevent dangerous situations and ensure a continuous, safe flow of gas. Always prioritize safety to avoid fire hazards.

Step 1: Inspect Before Use

Before each use, carefully inspect the entire length of the hose for any signs of wear, cracks, or damage. Check the connections at both ends to ensure they are secure and free of any oil, grease, or flammable residues. A damaged hose can leak, creating a highly flammable, oxygen-rich environment.

If you find any damage, no matter how small, the hose should be replaced immediately. Never attempt to repair a damaged hose with tape or other temporary fixes, as this will not withstand the pressure of the gas and could lead to a catastrophic failure.

Step 2: Ensure a Safe Environment

Maintain a safe distance between the oxygen hose and any heat sources, open flames, or sparks. Oxygen is not flammable, but it is a powerful oxidizer that can make other materials ignite and burn more intensely. Keep the hose away from all flammable materials.

Avoid using oil-based products, such as petroleum jelly, on or near the hose or any oxygen equipment. These substances can react violently with oxygen, causing a fire or explosion. Always use water-based lotions or lubricants for personal care in medical settings.

Step 3: Proper Handling and Storage

Handle the hose with care to prevent kinking, which can restrict flow or cause a weak point in the material. When not in use, store the hose in a clean, cool, and dry area away from direct sunlight and other heat sources. Never drape it over sharp objects.

Secure the hose to prevent tripping hazards. In both medical and industrial settings, a loose hose can be a serious danger to people and equipment. Use proper hose reels or hooks to keep it organized and off the floor when not in use.

What Distinguishes an Oxygen Hose from a Fuel Gas Hose?

While both hoses look similar and are often sold as a twin hose assembly, there are key differences that go beyond just color. These differences are rooted in the chemical properties of the gases they transport.

- Chemical Resistance: An oxygen hose is designed to be chemically inert to oxygen. In contrast, a fuel gas hose must be resistant to the specific fuel it carries. For instance, a hose for acetylene must resist the chemical properties of acetylene, while a hose for propane must be resistant to the oils found in that gas. This is where the hose grades (R, T, and RM) come into play, as discussed in our other articles.

- Fittings: The fittings on an oxygen hose and a fuel hose are typically threaded differently to prevent incorrect connections. Oxygen fittings usually have right-hand threads, while fuel gas fittings have left-hand threads. This is a crucial safety feature that makes it impossible to mix up the hoses.

- Hose Grade: While both hoses are rated for pressure, their internal composition is different to handle the specific gases they carry.

Conclusion

An oxygen hose is more than a simple tube; it is a critical component for both medical and industrial applications. Its specialized design, including reinforced materials and color-coding, is essential for safely transporting high-pressure oxygen, preventing accidents, and ensuring the reliability of critical processes.

The versatility of oxygen hoses is remarkable. In healthcare, they deliver life-sustaining oxygen to patients, while in industry, they are fundamental to welding and cutting. Their dual role highlights their importance in environments where safety and performance are equally critical.

When it comes to sourcing these vital components, quality is non-negotiable. Gushan Rubber is a leading manufacturer known for producing durable, high-quality industrial hoses that meet strict safety standards, ensuring your operations are both efficient and secure.

For a reliable supply of oxygen hoses, contact Gushan Rubber today to get your wholesale order.