Hydraulic hoses are essential components in numerous industrial and mechanical applications. They are responsible for transferring high-pressure hydraulic fluid to various components, powering everything from construction equipment to manufacturing machinery. However, with a myriad of hoses available, accurate identification is crucial for ensuring optimal performance, safety, and longevity.

In this blog post, we’ll delve into the key factors to consider when identifying hydraulic hoses, enabling you to make informed decisions and safeguard your operations.

What Is Hydraulic Hose Identification

Hydraulic hose identification is the process of determining the specific type and characteristics of a hydraulic hose. This information is crucial for ensuring the correct replacement or repair of hydraulic hoses, as well as for maintaining the overall safety and efficiency of hydraulic systems.

How to Identify Hydraulic Hose Size

Identifying Hydraulic Hose Size

Hydraulic hoses are typically sized by their inner diameter (ID), measured in inches. This measurement is often expressed in fractions or decimals.

Here are the common methods to identify hydraulic hose size:

1. Check the Hose Markings:

- Manufacturer‘s markings: Look for the manufacturer‘s name or logo, as well as any part numbers or size information printed on the hose.

- Size markings: The hose might have a direct indication of its size, such as “1/2” or “0.5”.

2. Measure the Inner Diameter (ID):

- Use a caliper: Carefully measure the inside diameter of the hose using a caliper.

- Use a ruler: If a caliper isn’t available, you can measure the outer diameter (OD) and the wall thickness, then subtract the wall thickness from the OD to get the ID. However, this method is less precise.

3. Refer to the Hose Fitting Size:

- Measure the fitting: The size of the fittings attached to the hose can often indicate the hose size.

- Consult a fitting size chart: Use a fitting size chart to correlate the fitting size to the hose size.

4. Consult a Hydraulic Hose Catalog or Supplier:

- Manufacturer‘s catalogs: Refer to the manufacturer‘s catalog for specific hose information, including size and compatibility.

- Hydraulic hose supplier: Consult with a hydraulic hose supplier who can help you identify the correct size based on your application and system requirements.

Important Considerations:

- Hose Wall Thickness: Different hose types have different wall thicknesses, which can affect the overall diameter of the hose.

- Hose Material: The material of the hose can influence its size and compatibility with different fluids.

- Pressure Rating: The hose’s pressure rating is crucial for ensuring it can withstand the operating pressure of your system.

By following these methods and considering the factors above, you can accurately identify the size of a hydraulic hose and select the appropriate replacement or upgrade.

Do you have any other questions about hydraulic hose identification or selection?

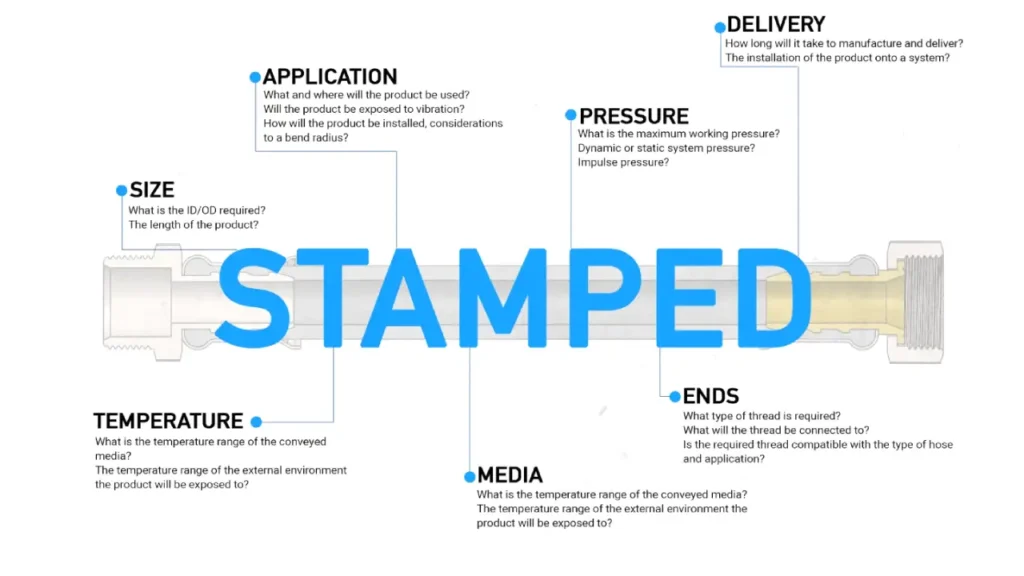

S.T.A.M.P.E.D. Hydraulic Hose Identification

The S.T.A.M.P.E.D. method is a helpful acronym for identifying the key factors to consider when selecting a hydraulic hose. It helps ensure that you choose the right hose for your specific application, reducing the risk of failure and improving system performance.

Here’s what each letter in S.T.A.M.P.E.D. stands for:

- S: Size (Inner diameter, outer diameter, and length)

- T: Temperature (Operating temperature range)

- A: Application (Specific use case, e.g., industrial, mobile, etc.)

- M: Media/Material (Fluid type and compatibility with hose material)

- P: Pressure (Operating pressure rating)

- E: End Fittings (Type and size of fittings required)

- D: Delivery (Flow rate and volume requirements)

By carefully considering each of these factors, you can select a hydraulic hose that is well-suited for your needs.

Hydraulic Hose Identification Labels

Hydraulic hose identification labels and tags are essential for ensuring the safe and efficient operation of hydraulic systems. These labels provide crucial information about the hose, such as its size, pressure rating, fluid compatibility, and hydraulic hose manufacturer.

Types of Hydraulic Hose Identification Labels:

There are several types of labels commonly used for hydraulic hose identification:

Printed Labels:

- Direct Printing: The information is printed directly onto the hose using ink or other printing methods.

- Self-Adhesive Labels: Labels are printed on adhesive-backed material and then applied to the hose.

Metal Tags:

- Stamped Tags: Metal tags with the necessary information stamped onto them.

- Engraved Tags: Metal tags with information engraved for durability.

Heat Shrink Tubing:

- Printed Tubing: Heat shrink tubing with printed information that is shrunk onto the hose.

Key Information to Include on Labels (for the hydraulic hose labeling systems)

- Manufacturer‘s Name: Identifies the manufacturer of the hose.

- Part Number: Unique identifier for the specific hose.

- Size: Inner diameter (ID) and outer diameter (OD) of the hose.

- Pressure Rating: Maximum pressure the hose can withstand.

- Temperature Range: Operating temperature limits.

- Fluid Compatibility: Types of fluids the hose can handle.

- Date of Installation: Records the date the hose was installed.

- Inspection Date: Schedule for regular inspections.

Factors to Consider When Choosing Hydraulic Hose Identification Labels:

- Durability: The label must withstand harsh environments, including exposure to hydraulic fluids, temperature extremes, and abrasion.

- Readability: The information on the label should be clear and easy to read.

- Adhesion: The label must adhere securely to the hose surface.

- Resistance to Chemicals: The label should be resistant to the chemicals used in hydraulic systems.

- Weather Resistance: The label should be able to withstand exposure to outdoor elements.

Proper Labeling Practices:

- Clear and Concise: Use clear and concise language on the labels.

- Consistent Placement: Place labels in a consistent location on the hose for easy identification.

- Regular Inspection: Regularly inspect labels for damage or fading.

- Update Labels: Update labels as needed, especially after repairs or replacements.

By using appropriate hydraulic hose identification labels and following best practices, you can improve safety, efficiency, and maintenance in your hydraulic systems.

Hydraulic Hose Identification Wrap

Hydraulic hose identification wraps are a popular solution for easily identifying hydraulic hoses and their corresponding connections. These wraps are typically made of durable materials like polyethylene and come in various colors and sizes to fit different hose diameters.

Key features and benefits of hydraulic hose identification wraps:

- Easy identification: Color-coded wraps and numbered markings make it easy to quickly identify the correct hose for each connection.

- Durability: Made from weather-resistant materials that can withstand harsh conditions and exposure to hydraulic fluids.

- Quick installation: No tools required for installation, simply wrap the hose and secure it in place.

- Long-lasting: The color is part of the molding process, so it won’t fade or crack over time.

- Versatile: Can be used on a variety of hydraulic hoses and equipment.

Popular brands and models:

- Outback Wrap: Offers a wide range of wraps in various colors and sizes, including specific kits for different equipment types.

- Other brands: Several other brands offer similar products with varying features and pricing.

How to choose the right identification wrap:

- Determine the hose size: Measure the diameter of your hoses to ensure the wrap fits securely.

- Consider the number of hoses: Choose a wrap kit that includes the appropriate number of wraps for your setup.

- Select the desired colors: Choose colors that are easy to distinguish and match your equipment’s color scheme.

- Check for additional features: Some wraps may include additional features like reflective strips or UV-resistant materials.

Proper installation and maintenance:

- Clean the hose: Ensure the hose is clean and dry before applying the wrap.

- Wrap securely: Wrap the hose tightly, but avoid over-tightening.

- Inspect regularly: Check the wraps periodically for damage or wear and replace them as needed.

By using hydraulic hose identification wraps, you can significantly improve the efficiency and safety of your hydraulic systems.

Conclusion

Elevate your hydraulic systems with premium-quality wholesale hydraulic hoses from Gushan Rubber. Our extensive range of hoses is designed to meet the rigorous demands of diverse industries.

Accurately identifying hydraulic hoses is crucial for ensuring optimal performance, safety, and longevity in various industrial and mechanical applications. By understanding the key components, markings, and factors to consider, you can confidently select the right hose for your specific needs.

Benefits of Choosing Us:

- Unmatched Quality: Our hoses are manufactured to the highest standards, ensuring durability and reliability.

- Diverse Selection: We offer a wide variety of hoses to suit different applications and pressures.

- Expert Guidance: Our knowledgeable team is ready to assist you in selecting the perfect hose for your needs.

- Competitive Pricing: Enjoy cost-effective solutions without compromising quality.

Don’t compromise on performance. Contact us today to explore our wholesale hydraulic hose options.