At first glance, a braided hose might seem like just any other hose, encased in a metal or fiber casing. But its design is a perfect example of engineering excellence. We’ve witnessed firsthand how this specialized construction enables it to withstand immense pressures and harsh environments. In this article, we’ll explain the mechanics behind this powerful component, breaking down its inner workings and revealing why it’s our preferred choice and that of our customers.

What is Braided Hose?

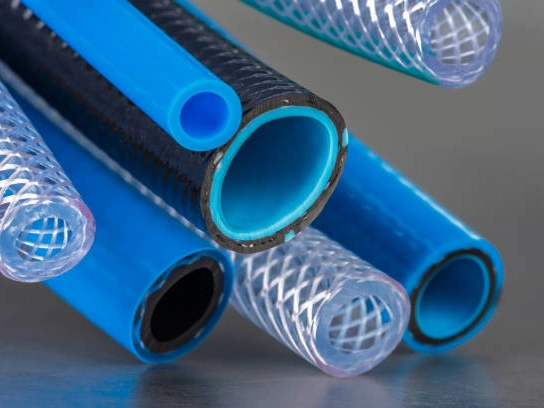

Before we can understand how it works, we must first look at its parts. The magic of a braided hose isn’t in a single component but in the synergy of its layers. We often describe it as a system working in harmony. Each layer has a specific function, and together, they provide the incredible performance characteristics that standard hoses can’t match.

We break down the hose into three main layers: the inner tube, the braided reinforcement, and the outer cover. Understanding the purpose of each layer is crucial to appreciating the overall design.

| Layer | Primary Function | Common Materials We Use |

| Inner Tube (Core) | To contain and transport the fluid. | Synthetic rubber, PTFE (Teflon), thermoplastic |

| Braided Reinforcement | To resist pressure and prevent hose expansion. | Stainless steel, aramid fiber (Kevlar), textile yarn |

| Outer Cover (Jacket) | To protect the inner layers from damage. | Rubber, polyurethane, PVC |

How Does Braided Hose Work

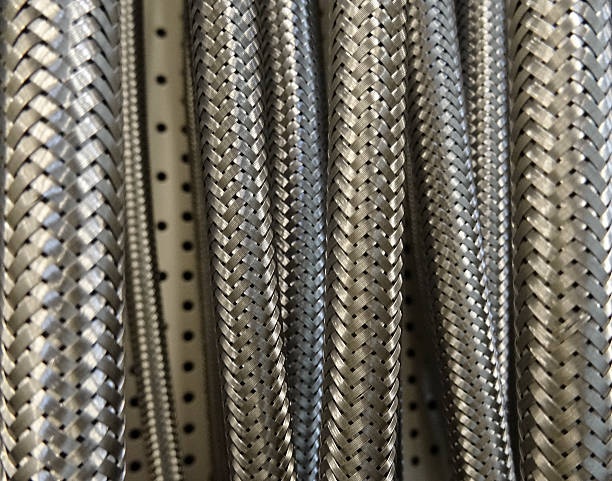

The core of “how a braided hose works” lies in its braided layer. When a fluid or gas is pressurized inside the hose, it exerts force on the inner walls. This force naturally tries to push outward and expand the hose. In a standard hose, this expansion can lead to weakening and, eventually, bursting.

The braid acts as a constricting force. The crisscrossing strands of steel wire or fiber form a tight, indestructible “cage” around the inner tube. This braided structure converts outward pressure into tension along the braid strands, effectively preventing the hose from expanding and maintaining its structural integrity.

This is a critical concept we explain to our customers: the braid isn’t just a shield; it’s an active component. It’s the reason a stainless steel braided hose can handle pressures far beyond what a conventional hose can. The braid’s angle and tension are meticulously engineered to maximize this effect, ensuring the hose can withstand system pressure without compromise.

Can Braided Hoses Handle High Temperatures and Chemicals?

When we talk to clients about specialized applications, we always emphasize the importance of material choice. The secret to handling extreme temperatures and corrosive chemicals is in the inner tube and the outer cover. For example, a PTFE braided hose is our top recommendation for chemical transfer. The PTFE (Teflon) inner tube is chemically inert, meaning it won’t react with or be degraded by most aggressive fluids. We’ve seen it perform flawlessly in chemical plants and manufacturing facilities where other materials would fail.

The outer braid also plays a key role here. While the inner tube handles the fluid, the braid provides strength, and the outer cover protects against environmental factors like heat and chemicals that could damage the core materials from the outside. The combination of these layers is what makes a braided hose a reliable choice for a wide variety of tough environments.

What Are the Advantages of Braided Hose?

Braided hoses offer a clear advantage over standard hoses, especially in demanding applications. We always tell our customers that their key advantage lies in the braid reinforcement, which provides superior strength and pressure resistance. A standard hose, simply a tube, can expand and weaken under pressure, leading to leaks or catastrophic bursts.

The braided design also offers exceptional durability. It protects the inner tube from external abrasion, cuts, and kinks, which are common causes of failure in non-reinforced hoses. This makes braided hoses more reliable and lasts longer, especially in demanding environments like underhoods or industrial settings.

While standard hoses may be cheaper and more flexible for simple tasks like watering the garden, the improved safety, performance, and longevity of braided hoses make them a wise choice for any critical fluid transfer job.

What are Braided Hoses Used For?

We’ve seen the power of braided hoses in action across countless industries. Here’s a look at how their unique mechanics translate into practical benefits for our customers.

Automotive & Motorsports: Pushing the Limits

- Brake Lines: The reason a braided brake line offers a firmer pedal feel is due to its anti-expansion properties. Without the hose expanding under pressure, all the force from the master cylinder is transmitted directly to the brake calipers, leading to more precise and responsive braking.

- Fuel and Oil Lines: The high pressures and temperatures in performance engines require a hose that won’t fail. The braid’s ability to resist pressure and the outer cover’s protection from engine bay heat make them the only safe option.

Industrial & Hydraulic Systems: The Backbone of Machinery

- Hydraulic Systems: The fundamental principle of hydraulics relies on fluid under extreme pressure to move heavy components. A hydraulic braided hose is the only type of flexible connection that can reliably handle this pressure without bursting. The braid is essential for containing the immense forces at play.

- Pneumatic Tools: While pressures are lower, the constant flexing and movement of pneumatic hoses in a workshop environment require durability. The braided layer protects against kinking and abrasion, ensuring a long service life.

How Do We Choose the Right Braided Hose?

As suppliers, we guide our customers through a selection process to ensure the hose they choose works as intended. We always emphasize that the right hose is a combination of the right materials for the job.

- Pressure Rating: We help clients calculate the maximum system pressure and then select a hose with a working pressure significantly higher than that. This safety margin is non-negotiable.

- Fluid Compatibility: We ensure the inner tube material is 100% compatible with the fluid it will be carrying. A mismatch can lead to catastrophic failure.

- Temperature Range: We check that the hose’s materials can withstand the full range of operating temperatures, from extreme cold starts to high-heat operating conditions.

- Environmental Factors: We consider if the hose will be exposed to sunlight (UV degradation), abrasion, or harsh chemicals and recommend an appropriate outer cover.

Conclusion

The inner tube carries the fluid, the braid withstands the pressure, and the outer layer provides comprehensive protection. In our experience, it is this functional design that makes braided hose more than just a product, but a vital safety and performance solution. If you would like to know more, please contact us.