Hydraulic hoses are typically designed to handle high-pressure fluids in hydraulic systems, but many wonder if these hoses can also be used for air applications. Understanding the differences between hydraulic fluid and air is essential, as using the wrong hose can affect performance, safety, and longevity.

Air and hydraulic fluids have distinct properties, including viscosity and compressibility. While some hydraulic hoses may withstand low-pressure air systems, proper evaluation of hydraulic hose material, pressure ratings, and fittings is crucial to ensure safe and efficient operation. Misuse can lead to leaks, bursts, or system failure.

Can a Hydraulic Hose Be Used for Air?

Hydraulic hoses are primarily designed for high-pressure fluid systems, but many wonder if they can also be used for air. Understanding the differences between hydraulic fluids and compressed air is essential, as improper use may lead to leaks, bursts, or reduced hose lifespan. Safety and efficiency depend on correct hose selection.

- Pressure ratings matter – Hydraulic hoses are rated for specific pressures. Using them with air requires checking if the hose can safely handle the system’s air pressure. Overestimating the hose’s capacity can result in dangerous bursts or damage. Proper selection ensures long-term reliability.

- Material compatibility – Hydraulic hoses are made from rubber, thermoplastics, or reinforced composites. Air may not react chemically with these materials, but temperature and pressure changes can affect flexibility. Choosing the right material prevents cracking, hardening, or premature failure under air conditions.

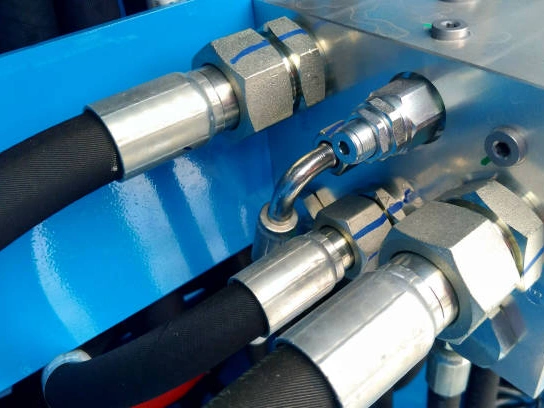

- Fittings and connections – Hydraulic hoses use fittings designed for fluid systems. When used with air, ensuring tight, leak-free connections is crucial. Improper fittings can cause pressure loss or hose detachment, creating safety hazards in compressed air systems.

- Intended application – While some low-pressure air applications may allow hydraulic hoses, high-pressure air systems require hoses specifically rated for pneumatic use. Assessing the intended system prevents inefficiency, damage, or safety risks, ensuring smooth and reliable operation.

What Is the Difference Between Hydraulic Hose and Air Hose?

To truly understand why hydraulic hoses aren’t suitable for use with air, we first need to understand the core difference between the two. While both are designed to transport pressurized fluid media, their construction and safety factors are designed around the specific properties of that media.

Hydraulic hoses are designed to transport incompressible fluids (oil), while air hoses are designed to transport highly compressible gases (air). This distinction is the reason we have two different types of hoses.

| Feature | Hydraulic Hose | Air Hose (Pneumatic) |

| Fluid Medium | Incompressible liquid (oil, fluid) | Highly compressible gas (air) |

| Pressure Type | Static, continuous force | Dynamic, often pulsating force |

| Reinforcement | Designed for high static pressure | Designed to contain explosive force, often with higher safety factors |

| Inner Tube Material | Specifically designed for compatibility with hydraulic oils | Designed to be less permeable to air and to dissipate static buildup |

| Pressure Rating | Typically rated with a 4:1 safety factor (burst pressure is 4x working pressure) | Rated with a 10:1 or higher safety factor due to the explosive risk of compressed air |

Why Air is Different from Oil

The biggest misconception I encounter is about pressure ratings. People see a high PSI rating on a hydraulic hose and assume it’s an over-engineered, safer option for a lower-pressure air system. But this is where the danger lies.

The key difference is the compressibility of the hydraulic fluid. When a hydraulic hose fails, the incompressible oil leaks out, and the pressure drops relatively quickly and non-violently. This is a mess, but it’s not an explosion.

Compressed air, on the other hand, is a different beast entirely. It stores a tremendous amount of potential energy. When an air hose fails, that stored energy is released instantly and explosively.

The hose can whip around with incredible force, turning into a projectile that can cause severe injury or death. The hose itself becomes a bomb. The safety factor of a hydraulic hose is simply not designed to contain this kind of explosive, sudden energy release.

How Much Pressure Can a Hydraulic Hose Handle?

The pressure rating stamped on a hydraulic hose is a critical piece of information, but it can be misleading when you’re considering an air application. A 3,000 PSI hydraulic hose is rated to safely contain hydraulic oil at a working pressure of 3,000 PSI.

The burst pressure, which is the pressure at which the hose is designed to fail, is typically four times the working pressure, around 12,000 PSI. This is the 4:1 safety factor standard for hydraulic systems.

For compressed air systems, the industry standard for a safety factor is much higher, often 10:1 or even more. This means a hose rated for 150 PSI of air pressure should have a burst pressure of at least 1,500 PSI.

While your 3,000 PSI hydraulic hose technically has a high burst pressure, its safety factor for air is only around 4:1. The explosive, high-energy nature of compressed air demands a higher safety margin to account for potential weaknesses, sudden impacts, or even small pinhole leaks that could trigger a catastrophic failure.

Can You Use a Hydraulic Hose for an Air Compressor?

Using a hydraulic hose on an air compressor is possible in some situations, but it’s not always the safest or most efficient choice. Hydraulic hoses are built for oil, not air, so the pressure behavior, temperature changes, and internal construction all play a role in whether the setup works reliably in real use.

- Check pressure compatibility — Make sure the hydraulic hose can handle your compressor’s maximum pressure rating, since air behaves differently than oil. Confirming this prevents dangerous hose expansion, sudden bursts, and helps maintain steady airflow without stressing the internal layers of the hose during long operation.

- Confirm hose material suitability — Ensure the hose material is compatible with compressed air, as some hydraulic hose interiors aren’t designed for dry gases. Proper material prevents internal cracking, reduces heat-related wear, and keeps the hose from degrading when exposed to constant air vibration and moisture.

- Inspect fittings and sealing surfaces — Air leaks more easily than oil, so the fittings must match perfectly and be sealed correctly. Tight, well-matched fittings prevent slow leaks, protect compressor efficiency, and avoid pressure loss that can make air-powered tools weaker or inconsistent during ongoing work.

- Monitor heat and flexibility changes — Compressed air can heat and cool rapidly, affecting hose flexibility. Watching for stiff spots, soft spots, or kinks helps you avoid fatigue failure, ensures smoother airflow, and keeps the hose performing reliably, even during frequent stop-and-go compressor cycles.

What Kind of Pipe Can I Use for an Air Compressor?

Choosing the right pipe for an air compressor starts with understanding pressure rating, material strength, and overall safety. Not all pipes can handle compressed air, and the wrong choice can crack, burst, or leak under load.

Selecting a durable, stable, and air-safe material keeps your system efficient and reduces downtime during daily use.

- Use aluminum air piping — Aluminum is lightweight, corrosion-resistant, and easy to install, making it popular for shop air systems. It handles steady pressure, reduces internal friction, and stays clean inside, keeping airflow smooth and reliable while avoiding rust flakes that could damage air tools over time.

- Choose copper piping — Copper offers strong pressure resistance and excellent durability without rust. It tolerates heat changes well and maintains a clean interior, reducing contamination risks. Although it costs more, it delivers long service life and stable pressure for compressors used in garages or small workshops.

- Consider stainless steel piping — Stainless steel is extremely tough and handles high pressure with confidence. Its rigid structure resists corrosion, rough environments, and vibration. This makes it ideal for heavy-duty industrial setups where long pipe runs, frequent cycles, and strong airflow are part of daily operation.

- Use reinforced flexible hose for short runs — Reinforced air hose works well between the compressor and fixed piping. Its flexibility helps absorb vibration, reduce stress on fittings, and make installation easier. It also handles pressure fluctuations better than rigid pipe during quick bursts, tool changes, or frequent startups.

Conclusion

In summary, while some hydraulic hoses can handle air under low-pressure conditions, it’s important to carefully consider hose specifications, materials, and pressure ratings before using them in air systems. Using the wrong hose can compromise safety and reduce the lifespan of your equipment.

Proper evaluation and consultation with hose experts ensure that your system operates efficiently and safely. Understanding the differences between hydraulic fluids and air applications helps prevent accidents, leaks, or system failures, making it crucial to choose the right hose for the job.

For reliable and hydraulic hoses that meet your system requirements, trust Gushan Rubber. Get your wholesale hydraulic hoses today and ensure top performance and safety for all your fluid and air applications.