Getting a clean, straight cut on a rubber hose is a small but critical step that determines the success and longevity of your entire assembly. A ragged or crooked cut can prevent proper sealing, lead to leaks, and ultimately cause premature system failure in automotive, industrial, or domestic applications.

This guide will show you how to cut a rubber hose perfectly every time, regardless of whether it’s a simple garden line or a reinforced hydraulic hose. We cover the essential tools and techniques needed to ensure a square, smooth edge that guarantees a reliable and secure connection with any fitting or clamp.

When to Cut Rubber Hoses?

Knowing exactly when to cut a rubber hose is as important as knowing how to cut it cleanly. Timing the cut is critical for assembly, repair, and replacement, directly impacting the hose’s functional fit and overall performance within a fluid transfer system.

- When Installing New Fittings: Always cut the hose immediately before installing new end fittings or connectors, ensuring the freshest possible, straight edge. This practice is vital for creating a perfect seal, especially with crimp-style fittings, as it prevents any material degradation or minor damage from affecting the crucial connection point.

- When Splicing a Damaged Section: If a hose develops a localized leak, bulge, or abrasion, cut out the damaged section immediately to prepare for a splice or repair. Cutting just beyond the compromised area ensures you remove all weak or failed material, thereby preventing the damage from propagating further down the hose.

- During Custom Length Fabrication: Rubber hoses must be cut precisely to the required length before assembly or system installation to eliminate excess slack or strain. Measuring carefully and cutting exactly to specification ensures proper routing, prevents kinking, and avoids putting unnecessary stress on the hose fittings and connection points.

- When the Hose End is Deformed: Cut and discard a short portion of the hose end if it becomes crushed, jagged, or damaged during handling or removal. A clean, square end is essential for a leak-proof connection; attempting to fit a deformed end will inevitably result in a poor seal and subsequent connection failure.

How to Cut a Rubber Hose?

Achieving a perfectly straight, smooth cut on a rubber hose is crucial for preventing leaks and ensuring a secure connection to fittings. Using the correct tools and a precise technique is key, especially when dealing with reinforced or thick-walled hose types.

Step 1: Measure and Mark the Cut Line

Carefully measure the required length of the hose, accounting for the length of the end fittings. Use a ruler or measuring tape and a piece of chalk or a fine-tip marker to draw a clear line exactly where the cut needs to be made.

Ensure your mark is perfectly perpendicular to the length of the hose. A straight cut is essential for the fitting to seal correctly; any angle or unevenness will compromise the integrity of the finished hose assembly.

Step 2: Secure the Hose and Apply Guide Tape

Firmly secure the hose in a vise or clamp, taking care not to crush or distort its shape. Position the marked cut line right where your cutting tool will contact the hose, making sure the rest of the hose is stable.

For extra precision, tightly wrap a piece of masking tape or a hose clamp around the hose, aligning its edge perfectly with your marked line. This acts as a rigid guide, helping the blade stay straight and preventing the rubber from tearing.

Step 3: Select the Appropriate Cutting Tool

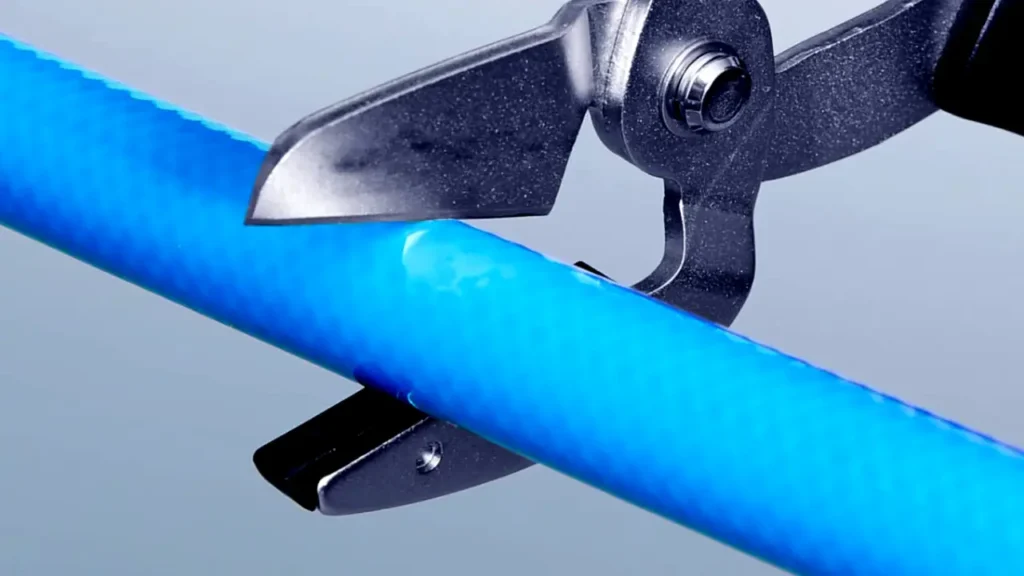

For non-reinforced or small-diameter hoses, use a dedicated sharp hose cutter or a new, sharp utility knife/razor blade. A dull blade will tear the rubber and result in a ragged, unusable end that compromises the connection.

For reinforced hoses, especially those with braided wire (like hydraulic lines), a fine-toothed saw blade or a specialized chop saw designed for hose cutting is required. These tools are necessary to cut through the reinforcement cleanly without fraying the metal strands.

Step 4: Make a Controlled, Straight Cut

Apply a light lubricant, such as soapy water or a silicone spray, to the blade before cutting, which helps the tool glide through the rubber smoothly. For a manual cut, use steady, continuous pressure around the guiding edge.

Avoid sawing back and forth on soft hoses, as this promotes a crooked cut and material fraying. Instead, rotate the hose gradually while maintaining consistent pressure, ensuring the cut stays precisely on the marked guide line at a perfect 90-degree angle.

Step 5: Clean and Deburr the Cut End

After cutting, inspect the end for any small tags of rubber, fabric, or stray wire reinforcement strands. Use a sharp utility knife or a deburring tool to carefully trim and clean up the interior and exterior edges of the cut.

It is critical that the inner diameter is completely clear of debris and reinforcement pieces, particularly for hydraulic or pressure hoses. A clean bore ensures unobstructed fluid flow and prevents material from contaminating the system or fouling the fitting.

Best Way to Cut Rubber Hose

The best way to cut a rubber hose achieves a perfectly straight, square edge without deforming the hose wall or fraying any internal reinforcement materials. A clean cut is paramount for a secure, leak-proof connection, especially when dealing with pressurized systems that rely on an effective seal.

- Use a Specialized Hose Cutter: For non-braided and low-pressure hoses, specialized hose cutters (pliers-style or guillotine cutters) provide the cleanest, fastest result. These tools are designed to shear the hose material perpendicular to its axis, preventing the compression and subsequent distortion that occurs when using general-purpose knives or scissors.

- Employ a Razor Knife with a Guide: When a dedicated cutter is unavailable, a new, sharp utility knife or razor blade used with a guide offers excellent precision. Clamp a hose clamp or masking tape exactly on your cut line to serve as a rigid fence, guiding the blade to maintain a flawless 90-degree angle as you slowly rotate the hose.

- For Reinforced Hoses: Utilize a Fine-Toothed SawHoses containing wire braiding or steel spiral reinforcement (like high-pressure hydraulic hose) require a fine-toothed metal-cutting saw, such as a hacksaw or dedicated hose chop saw. Secure the hose firmly in a vise and apply gentle, even pressure to slice through the wire without causing it to fray or unravel.

- Lubricate the Blade for Smoother Cuts: Before cutting any thick rubber hose, lubricate your blade or saw with a small amount of water or silicone spray. This simple step significantly reduces friction and drag, allowing the blade to glide through the rubber instead of grabbing and tearing it, ensuring a cleaner, professional-grade edge.

Conclusion

Achieving a precise, perpendicular cut is the secret to a professional and leak-free hose assembly. By using the correct, sharp cutting tools and following our measured techniques, you eliminate fraying and deformation, ensuring your hose ends mate perfectly with their fittings for maximum pressure integrity and system reliability.

Consistent attention to detail in the cutting process significantly extends the service life of your hoses and prevents costly repairs or replacements down the line. Remember: a high-quality connection begins with a clean-cut end. Never compromise on precision, as it is the foundation of a safe and high-performing fluid transfer system.

For all your industrial, hydraulic, or custom-application needs, turn to reliable manufacturing. When it’s time to replace or upgrade your inventory, ensure you are investing in quality by choosing to get wholesale rubber hoses from our Gushan Rubber. We offer a durable and extensive selection to meet every demanding specification.