What’s the lifespan of a wire braided hose? This question is difficult to answer because the lifespan of these hoses varies greatly, influenced by numerous factors. While well-made stainless steel braided hoses can provide years of reliable service, inferior or improperly used hoses can fail prematurely. In this guide, we’ll delve into the key factors that influence hose lifespan, providing you with the knowledge to maximize hose lifespan and ensure the safety of your fluid transfer system.

What Factors Influence a Hose’s Lifespan?

The lifespan of a steel braided hose isn’t just about the material it’s made from. It’s a complex equation involving its design, the environment it’s used in, and the specific fluids it carries. We’ve seen hoses last a lifetime in one application and fail in a matter of months in another.

By understanding these variables—from temperature and pressure to chemical exposure and installation—you can move from a state of uncertainty to one of proactive maintenance, ensuring your hoses perform for as long as possible.

Does Material Quality Matter?

The quality of the materials is the foundation of a hose’s lifespan. A high-quality stainless steel braided hose will use a durable inner liner, such as PTFE or a premium synthetic rubber, along with a strong, corrosion-resistant stainless steel braid.

A cheap alternative might use a lower-grade rubber that degrades from exposure to modern fuels or a braid that rusts and frays. We always tell our clients that a small investment in a reputable brand’s hose pays off exponentially in the long run by preventing costly failures and replacements.

What’s the Role of Pressure and Temperature?

Pressure and temperature are two of the most critical factors affecting hose longevity. Every hose is designed with a specific working pressure and temperature range. Exceeding these limits, even occasionally, puts immense stress on the hose’s components.

- Pressure Spikes: Sudden spikes in pressure—often caused by quick valve closures or pump start-ups—can fatigue the hose’s reinforcement. Over time, these spikes can weaken the braid and inner liner, leading to a rupture.

- High Temperatures: Exposure to temperatures outside the hose’s rated range can cause the inner liner to harden, crack, or become excessively soft. This makes the hose more vulnerable to pressure and external damage. For example, a standard rubber hose will quickly degrade when used for high-temperature steam.

We always recommend selecting a hose that has a safety factor well above the maximum anticipated pressure and temperature of your system to ensure long-term reliability.

How Does Chemical Exposure Affect Longevity?

This is a major point of failure we see. The inner liner of a steel braided hose must be chemically compatible with the fluid it’s transferring. A common mistake is using a standard rubber hose for a fluid with a high ethanol content.

The ethanol will cause the rubber to swell and deteriorate from the inside out, leading to leaks and eventual failure. A PTFE braided hose, with its superior chemical resistance, would be the correct choice for such an application. We always advise our customers to consult a chemical compatibility chart before selecting a hose.

Does Installation Technique Play a Role?

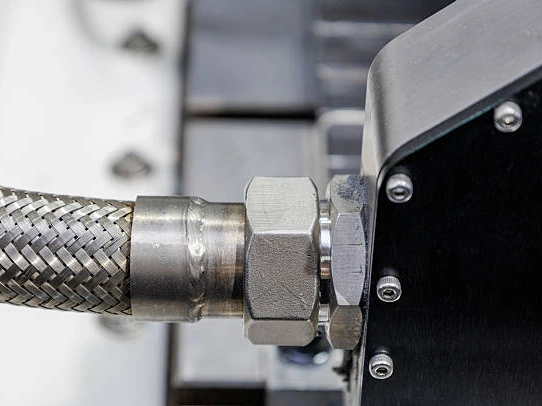

A perfectly good steel braided hose can have its life cut short by a poor installation. We’ve seen it countless times. Here’s what we look out for:

- Twisting: When a hose is installed with a twist, the reinforcement braid is put under constant stress. This can cause the hose to fail prematurely, often near the fittings.

- Exceeding Minimum Bend Radius: Forcing a hose into a tighter bend than it’s designed for can cause a kink, which restricts flow and weakens the hose at the bend.

- Abrasion: Routing a hose where it rubs against other components is a recipe for disaster. Over time, this constant friction will wear through the outer braid and the inner liner, leading to a catastrophic leak. We always recommend using abrasion sleeves or proper clamping to prevent this.

How Long Do Steel Braided Hoses Last

While we can’t give a single number, we can provide a realistic range based on our experience.

- Typical Lifespan: With proper installation and use, a high-quality stainless steel braided hose can last anywhere from 5 to 15 years in most applications.

- Ideal Conditions: In a clean, low-stress environment with no exposure to damaging factors, a hose could potentially last for 20 years or more.

- Harsh Conditions: In a high-vibration, high-pressure, or chemically aggressive environment, the lifespan could be as short as 2 to 5 years, or even less without proper maintenance.

Regular inspection is key. We recommend checking your hoses for signs of wear—like frayed braid, visible cracking, or bulges—at least once a year.

Which is Better Steel Braided Hose or Rubber Hose?

Choosing between a steel braided hose and a rubber hose depends entirely on the application’s demands. Steel braided hoses are superior for high-pressure, high-temperature, and corrosive environments. The outer stainless steel mesh provides exceptional durability, preventing expansion under pressure and offering excellent abrasion resistance. This makes them ideal for demanding uses like automotive brake lines, fuel systems, and industrial hydraulics.

Rubber hoses are more flexible and cost-effective, making them suitable for low-to-moderate pressure applications where movement is a key factor. They are also easier to install in tight spaces due to their pliability. While modern rubber hoses are more resilient than ever, they lack the structural integrity and durability of steel braided hoses, especially when exposed to extreme conditions or sharp objects. Ultimately, steel braided hoses offer a significant upgrade in terms of safety and longevity for critical systems.

Conclusion

The lifespan of your wire braided hose isn’t a matter of luck; it’s a matter of making smart decisions. By investing in quality products, understanding your system’s operating conditions, and prioritizing proper installation and maintenance, you can ensure a long, reliable hose life.