Modern machinery wouldn’t function without hydraulic systems, and the crucial “veins” of these systems are hydraulic hoses. You might not realize it, but hydraulic power is all around us—from the construction site down the street to the plane you’re boarding for vacation. This article will take you on a deep dive into the extensive world of hydraulic hose applications, revealing how these essential components power our modern lives.

What is a Hydraulic Hose?

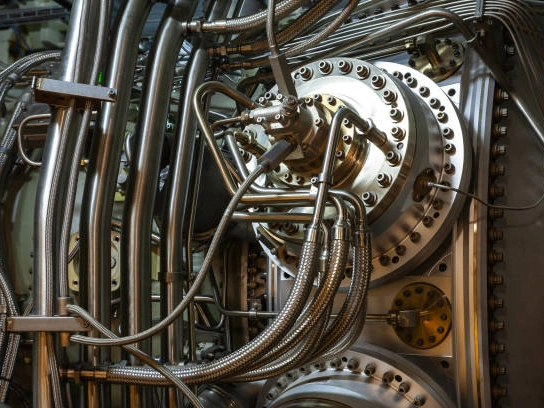

Hydraulic hose is a flexible conduit designed to carry high-pressure hydraulic fluid, which transmits power from a pump to an actuator within a hydraulic system. These hoses must withstand immense internal pressure, extreme temperature fluctuations, and various external environmental stresses.

That’s why they typically feature a multi-layer construction: a fluid-resistant inner tube, a braided or spiral steel wire reinforcement, and a durable outer layer that’s resistant to abrasion and weathering. This complex construction ensures they operate reliably and safely even in the harshest conditions.

The Diverse World of Hydraulic Hose Applications

Hydraulic hoses are used not only in heavy machinery but are an integral part of countless industries and everyday technology. By exploring these applications, we can better understand the vital role hydraulics plays in modern society.

1. Construction and Heavy Machinery

On any construction site, hydraulic hoses are the very heart and muscle of the equipment. They are indispensable for excavators, bulldozers, cranes, and loaders. These hoses channel high-pressure fluid to hydraulic cylinders, enabling the machine to perform tasks like lifting heavy beams, digging trenches, or moving massive piles of earth.

In these brutal environments, hydraulic hoses must possess superior resistance to abrasion, UV light, and extreme pressure to withstand constant exposure to dirt, rocks, and intense, continuous operation. Without them, these powerful machines would be rendered useless.

2. Agriculture and Farming Equipment

In modern agriculture, efficiency and automation are critical for meeting global food demand. Farm machinery like tractors, combine harvesters, and planters relies on hydraulic systems to precisely control their various functions.

For example, hydraulic hose applications include controlling the height of a harvester’s header, lifting and lowering a tractor’s attachments, and adjusting the depth of a planter’s blades. These hoses must be exceptionally durable to resist chemical corrosion from pesticides and fertilizers and maintain their flexibility and performance in all weather conditions, from scorching sun to freezing cold.

3. Aerospace and Defense

In the aerospace industry, safety is the top priority. Hydraulic systems are indispensable in aircraft, controlling critical functions like the extension and retraction of landing gear, the movement of flaps and ailerons, and the activation of braking systems. In these applications, hydraulic hoses must meet incredibly strict standards, as they need to withstand extreme temperature differentials, high altitude pressure, and intense vibrations.

In the defense sector, vehicles and equipment such as military trucks and naval vessels rely on hydraulic systems for steering, braking, and weapons systems, where reliability is a matter of national security.

4. Manufacturing and Industrial Automation

Within factories and manufacturing plants, hydraulic hoses are key components in a wide range of automated equipment and robotics. They provide the power for injection molding machines, hydraulic presses, and the various clamps and tools on assembly lines.

These applications often demand hoses that can provide precise control and withstand repetitive, high-cycle operations. Furthermore, in industries like metallurgy, paper mills, and plastics, hydraulic hoses are engineered to handle heavy machinery and high-temperature environments, requiring exceptional heat and chemical resistance to operate safely and effectively.

Choosing the Right Hydraulic Hose for Your Application

Selecting the correct hydraulic hose is a critical decision that impacts not only performance but, more importantly, safety. A wrong choice can lead to hose failure, fluid leaks, and potentially catastrophic accidents. Here are the key factors I always consider when choosing a hose for a specific application.

| Factor | Description | Consequence of a Wrong Choice |

| Working Pressure | The hose must be able to withstand the system’s maximum operating pressure with a generous safety margin. | Hose rupture, high-pressure fluid injection, and severe injury. |

| Temperature Range | Both the hose’s inner and outer layers must be compatible with the fluid and the ambient temperatures. | Material degradation, hardening, or softening, leading to leaks and performance issues. |

| Fluid Compatibility | The hose material must be compatible with the specific hydraulic fluid or other media being transported. | Inner tube corrosion or swelling, introducing debris into the system and damaging components. |

| Bend Radius | The hose should not be bent too tightly during installation, as this restricts fluid flow and shortens its lifespan. | Damage to the hose’s internal structure, leading to premature failure. |

| Size | The hose’s inner diameter must match the flow requirements to prevent pressure loss and excessive heat generation. | Inefficient system operation, overheating, and potential component damage. |

Can I Use a Hydraulic Hose for Gasoline?

It is not safe to use a standard hydraulic hose for gasoline. These hoses are designed specifically for hydraulic fluids, which have very different chemical properties from gasoline. Using the wrong hose can lead to a dangerous failure, risking leaks, fire, and explosions. The primary issue is material incompatibility.

The inner layer of a hydraulic hose is made from compounds that are not resistant to the corrosive nature of gasoline, especially modern fuels containing ethanol. Over time, gasoline will cause this inner lining to break down, leading to softening, swelling, or blistering. This internal damage weakens the hose’s structure, making it highly susceptible to bursting under pressure.

Another major risk is fire and safety. Gasoline is highly flammable, and any leak from a degraded hose poses a serious fire hazard. Additionally, a standard hydraulic hose lacks the antistatic properties required for safe fuel transfer. As gasoline flows, it can build up static electricity, which could create a spark and ignite fuel vapors. Hoses designed for fuel, such as those that meet SAE J30 standards, are specifically engineered to safely dissipate static charge and withstand the corrosive effects of fuel. For these reasons, it is essential to use a hose that is explicitly rated and certified for fuel applications.

Maintaining Your Hydraulic Hoses

Proper maintenance is the key to ensuring safe and efficient hydraulic hose applications. A regular inspection and maintenance schedule can help you identify potential issues before they become costly failures.

- Routine Inspection: Make hose inspection a part of your monthly maintenance checklist. Look closely for any cracking, swelling, or abrasion on the outer cover. Also, check for any hardening of the material or leaks around the fittings and couplings. These are early warning signs of potential failure.

- Keep Them Clean: A clean hose is a healthy hose. Regularly wipe away any oil residue, dirt, or debris. A build-up of grime can mask damage and prematurely degrade the outer rubber cover. A clean surface makes it easier to spot issues during inspections and helps the hose perform at its best.

- Avoid Over-Bending: During installation, ensure your hoses have enough slack and clearance to prevent tight bends, twisting, or kinking. Hoses should never be stretched tight. This kind of stress can cause internal reinforcement layers to break down, leading to an unexpected rupture.

- Proper Storage: Unused spare hoses should be stored in a cool, dry, and dark environment. Keep them away from direct sunlight, which can degrade the rubber, and from chemicals that can cause corrosion. Proper storage ensures your spare hoses are in perfect condition when you need them.

- Timely Replacement: Don’t wait for a hose to fail. Follow the manufacturer’s recommended service life or industry standards for proactive replacement. Even a hose that looks fine on the outside can be suffering from material aging on the inside. Replacing it on schedule is a smart investment in safety and reliability.

Conclusion

From the powerful machinery on construction sites to the precision equipment in factories, hydraulic hose applications are everywhere. They are the unsung heroes of modern engineering. By understanding their different types, making the right choices, and committing to proper maintenance, we can ensure not only the smooth operation of our equipment but also the safety of those who work with it.

We hope this article has given you a newfound appreciation for the role of hydraulic hoses. Do you have any questions about maintaining or choosing the right hose for your needs? Share them in the comments below!