Hydraulic hoses are critical components in many industrial and commercial applications, powering everything from heavy machinery to automotive systems.

Over time, these hoses are subjected to various stresses, including pressure, temperature extremes, and physical damage. As a result, they can deteriorate, leading to potential leaks, failures, and safety hazards. To mitigate these risks, regular hydraulic hose inspection is essential.

This blog post will delve into identifying wear and tear in hydraulic hoses. We will explore common signs of deterioration, discuss effective inspection techniques, and provide guidance on timely replacement. By understanding these factors, you can ensure the safety and reliability of your hydraulic systems.

Why Hydraulic Hose Inspection is Important

Hydraulic hoses are the lifeblood of many industrial and commercial operations. They are subjected to constant pressure, temperature fluctuations, and exposure to harsh environments. As a result, they are prone to wear and tear, which can lead to serious consequences, including:

- Equipment Failure: A ruptured hose can cause sudden and catastrophic equipment failure, leading to production downtime and financial loss.

- Safety Hazards: Leaking hydraulic fluid can create slippery surfaces, posing a significant safety risk to workers. Additionally, hydraulic fluid can damage equipment and the environment.

- Increased Operational Costs: Frequent hose replacements and unplanned downtime can significantly increase operational costs.

Regular hydraulic hose inspection is essential to prevent these issues. By identifying potential problems early on, you can take proactive measures to avoid costly repairs and downtime.

Key areas to inspect during a hydraulic hose inspection include:

- Visual Inspection: Check for cuts, cracks, abrasions, and signs of excessive wear.

- Pressure Testing: Verify that the hose can withstand the required operating pressure.

- Flex Testing: Assess the hose’s flexibility and resistance to fatigue.

- Coupling Inspection: Examine the couplings for damage, corrosion, and proper tightening.

By incorporating regular hydraulic hose inspections into your maintenance routine, you can significantly improve the reliability and safety of your hydraulic systems.

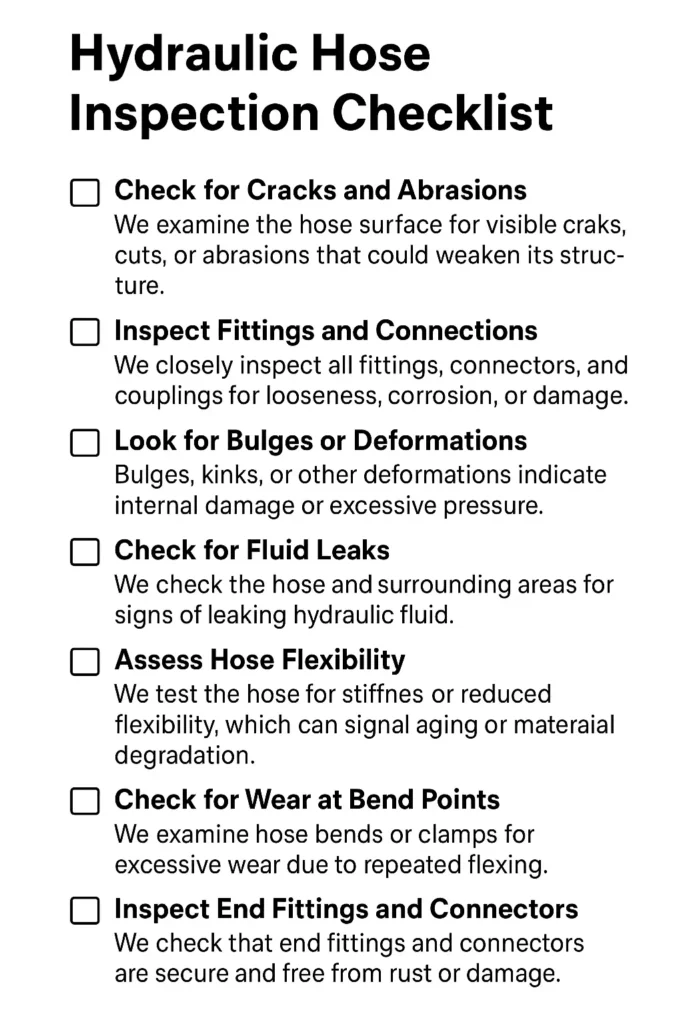

Hydraulic Hose Inspection Checklist

Regular hydraulic hose inspection is essential to ensure safety, prevent leaks, and maintain system efficiency. By identifying wear and tear early, you can schedule timely replacements and avoid costly downtime or equipment damage. We provide a comprehensive checklist to guide you through a thorough inspection process.

- Check for Cracks and Abrasions: We examine the hose surface for visible cracks, cuts, or abrasions that could weaken its structure. Detecting these early allows us to replace or repair damaged sections, preventing leaks, ruptures, and potential hydraulic system failures, ensuring smooth and safe operation.

- Inspect Fittings and Connections: We closely inspect all fittings, connectors, and couplings for looseness, corrosion, or damage. Properly secured connections prevent fluid leaks and pressure loss, maintaining system efficiency. Timely attention to these components ensures the hose performs reliably under high-pressure conditions.

- Look for Bulges or Deformations: Bulges, kinks, or other deformations indicate internal damage or excessive pressure exposure. We monitor these signs carefully, as they can lead to sudden hose failure. Early identification allows corrective action, prolonging hose life and safeguarding equipment and operators.

- Check for Fluid Leaks: We check the hose and surrounding areas for signs of leaking hydraulic fluid. Even minor leaks can indicate internal wear or fitting issues. Addressing leaks promptly ensures optimal system performance, prevents environmental hazards, and reduces maintenance costs.

- Assess Hose Flexibility: We test the hose for stiffness or reduced flexibility, which can signal aging or material degradation. Maintaining proper flexibility is crucial for safe movement and pressure handling. Timely replacement or repair preserves system integrity and prevents unexpected failures.

What to Inspect for Hydraulic Hose Testing

Proper hydraulic hose testing is crucial to ensure safety, reliability, and optimal system performance. Regular inspection helps detect wear, prevent leaks, and extend hose life. We guide you through essential areas to examine during testing.

- Cracks on Hose Surface: We check for visible cracks or splits that can compromise hose integrity and lead to leaks or failure. Early detection allows timely replacement, preventing costly downtime.

- Abrasions or Cuts: We inspect the hose for abrasions, nicks, or cuts caused by contact with surfaces, tools, or debris. Addressing these issues maintains structural strength.

- Kinks or Twists: Hoses twisted or kinked can reduce flow and increase pressure on the material. We ensure hoses are straight and flexible for safe operation.

- Bulges or Blisters: Bulges indicate internal damage or excessive pressure. We monitor and replace hoses showing deformities to avoid sudden bursts.

- Loose Fittings: Loose connectors can cause leaks or disconnections. We tighten and inspect all fittings to maintain secure connections.

- Corrosion on Fittings: Metal corrosion can weaken hose connections. We check and clean fittings, replacing them when necessary.

- Leak Detection: We examine hoses for visible fluid leaks, which may indicate internal wear or damaged fittings. Prompt repair prevents hazards.

- Pressure Testing: We test hoses under rated pressure to verify their ability to handle operational demands safely.

- Flexibility Check: We assess hose pliability; stiff hoses may indicate aging or material degradation, requiring replacement.

- Temperature Damage: We inspect for heat or cold damage, which can reduce hose lifespan or compromise performance.

- Wear at Bend Points: We examine areas near bends or clamps for excessive wear due to repeated flexing.

- Abrasion Sleeves Condition: We check protective sleeves for wear, ensuring they continue to shield hoses from friction.

- Label and Marking Visibility: We verify that hose identification markings are intact for correct usage and replacement tracking.

- End Cap Condition: We inspect end caps to ensure no damage, contamination, or leaks exist.

- Swelling or Soft Spots: Soft areas on hoses may indicate internal material breakdown or fluid saturation.

- Vibration Damage: We check hoses exposed to vibration for wear or loosening, preventing premature failure.

- Chemical Exposure Signs: We identify hoses exposed to incompatible fluids or chemicals that may degrade material.

- Abrasion from Adjacent Components: We look for rubbing against equipment or surfaces that could erode the hose.

- Twist Direction Consistency: We verify hoses are installed according to manufacturer’s twist recommendations to prevent stress.

- Connector Wear: We examine threaded or quick-connect fittings for wear or damage.

- Crimped Area Integrity: We inspect crimped ends for secure attachment and no deformities.

- Fluid Contamination: We check hoses for signs of internal fluid contamination that can damage the system.

- Hose Length Consistency: We ensure hoses are the correct length without stretching or sagging.

- Protective Coverings: We inspect sleeves or wraps for damage to maintain hose protection.

- Compliance with Standards: We verify hoses meet industry standards for safety, pressure, and temperature requirements.

Hydraulic Hose Inspection Procedure

1. Visual Inspection:

Hose Surface:

- Check for cuts, cracks, abrasions, or other signs of physical damage.

- Look for evidence of heat damage, such as discoloration or blistering.

- Inspect for any signs of chemical exposure, such as swelling or softening.

Hose Fittings:

- Verify that all fittings are securely tightened.

- Check for leaks at the connections.

- Inspect for corrosion or damage to the fittings.

Hose Clamps:

- Ensure that clamps are secure and not damaged.

- Verify that clamps are properly positioned.

- Check for any sharp bends or kinks in the hose.

- Ensure that the hose is routed away from heat sources and sharp edges.

- Verify that the hose is not excessively stretched or compressed.

2. Functional Inspection:

Pressure Testing:

- Use a pressure gauge to verify that the hose can withstand the required operating pressure.

- Check for any leaks during pressure testing.

Flex Testing:

- Bend the hose to assess its flexibility and resistance to fatigue.

- Look for any signs of cracking or weakening in the hose.

Additional Considerations:

Hose Age:

Consider the age of the hose and its expected lifespan.

Replace hoses that have exceeded their recommended service life.

Operating Environment:

Take into account the harshness of the operating environment, such as exposure to extreme temperatures, chemicals, or vibration.

Maintenance Records:

Keep detailed records of all inspections and maintenance performed on hydraulic hoses.

Frequency of Inspection:

The frequency of inspection depends on several factors, including:

- Operating Environment: Harsh environments may require more frequent inspections.

- Hose Age: Older hoses may need more frequent checks.

- Usage: Heavy-duty applications may necessitate more frequent inspections.

General guidelines:

- Monthly Inspections: For most applications, monthly visual inspections are recommended.

- Annual Inspections: Annual pressure testing and flex testing are typically sufficient.

Remember:

- Trained Personnel: Ensure that inspections are performed by trained and qualified personnel.

- Corrective Action: Take immediate corrective action for any identified issues.

- Replacement: Replace damaged or worn hoses promptly to prevent further damage and downtime.

By following this procedure and conducting regular inspections, you can help ensure the safety and reliability of your hydraulic systems.

Hydraulic Hose Inspection Criteria

Regular hydraulic hose inspection is vital for maintaining system safety, preventing leaks, and ensuring optimal performance. By identifying wear, damage, and potential failures early, you can schedule timely replacements and reduce downtime. We provide a comprehensive checklist to help you inspect hoses effectively and efficiently.

- Surface Cracks or Cuts: We examine hoses for visible cracks, splits, or cuts that compromise integrity. Early detection allows prompt replacement, preventing leaks, system failures, and costly downtime while ensuring safe hydraulic operation.

- Abrasion and Wear: Hoses exposed to rubbing, friction, or sharp edges can develop abrasions. We check for wear patterns to maintain strength and durability, addressing weak spots before they lead to catastrophic failure.

- Kinks or Twists: Hoses with kinks or twists reduce fluid flow and increase stress. We inspect installation and alignment to ensure smooth bends, preventing pressure buildup, premature wear, and potential ruptures.

- Bulges and Blisters: Bulges or blistering indicate internal damage or overpressure. We identify these early to replace or repair hoses, avoiding sudden bursts and ensuring safe, reliable hydraulic operation.

- Loose or Damaged Fittings: Connectors, couplings, or threaded ends can loosen or corrode over time. We inspect fittings to maintain secure connections, prevent leaks, and guarantee proper system functionality.

- Leaks or Fluid Residue: Any signs of fluid leakage indicate worn hoses, damaged fittings, or internal failure. We detect leaks early to maintain system efficiency, reduce environmental hazards, and prevent equipment damage.

- Flexibility and Stiffness: Loss of hose flexibility signals aging or material degradation. We assess hose pliability to ensure it can handle pressure, movement, and vibration without failure.

- Temperature or Chemical Damage: Exposure to extreme heat, cold, or chemicals can weaken hoses. We inspect for discoloration, brittleness, or material breakdown to maintain system safety and longevity.

- Protective Sleeves and Covers: We check abrasion sleeves, wraps, or protective coatings for wear or damage. Proper protective layers extend hose life and prevent external damage from contact with surfaces or other components.

- Compliance with Industry Standards: Hoses must meet pressure, temperature, and safety requirements. We verify compliance with manufacturer and industry standards, ensuring operational safety and reliability in hydraulic systems.

How Often Should Hydraulic Hoses Be Tested

The frequency of hydraulic hose testing depends on several factors, including:

- Operating Environment: Harsh environments may require more frequent inspections.

- Hose Age: Older hoses may need more frequent checks.

- Usage: Heavy-duty applications may necessitate more frequent inspections.

General guidelines:

- Monthly Inspections: For most applications, monthly visual inspections are recommended.

- Annual Inspections: Annual pressure testing and flex testing are typically sufficient.

However, it’s important to note that these are general guidelines, and the specific inspection frequency should be determined based on a risk assessment and the manufacturer‘s recommendations.

Additional Tips:

- Keep detailed records of all inspections and maintenance performed on hydraulic hoses.

- Replace damaged or worn hoses promptly to prevent further damage and downtime.

- Consult with a hydraulic hose specialist to determine the optimal inspection frequency for your specific application.

By following these guidelines and conducting regular inspections, you can help ensure the safety and reliability of your hydraulic systems.

How to Inspect a Hydraulic System

Regular inspection of a hydraulic system is essential to ensure safety, efficiency, and long-term performance. By following a systematic approach, you can detect wear, leaks, or component failures early and maintain optimal operation of your equipment.

Step 1: Check Fluid Levels

We start by inspecting the hydraulic fluid level to ensure it is within the recommended range. Low fluid levels can cause pump cavitation, reduce system efficiency, and increase wear, leading to potential system failure if not addressed promptly.

We also examine the fluid for contamination, discoloration, or unusual odor. Maintaining clean, high-quality hydraulic fluid is crucial for smooth system operation, preventing damage to pumps, valves, and cylinders, and extending the overall lifespan of the hydraulic system.

Step 2: Inspect Hoses and Lines

We examine all hydraulic hoses and lines for cracks, bulges, kinks, or signs of abrasion. Detecting these issues early helps prevent leaks, ruptures, or sudden system failure, ensuring safe and reliable operation under pressure.

We also check hose fittings and connectors for looseness, corrosion, or wear. Properly secured connections prevent fluid leaks, maintain system pressure, and enhance the overall performance and longevity of the hydraulic system, reducing maintenance costs.

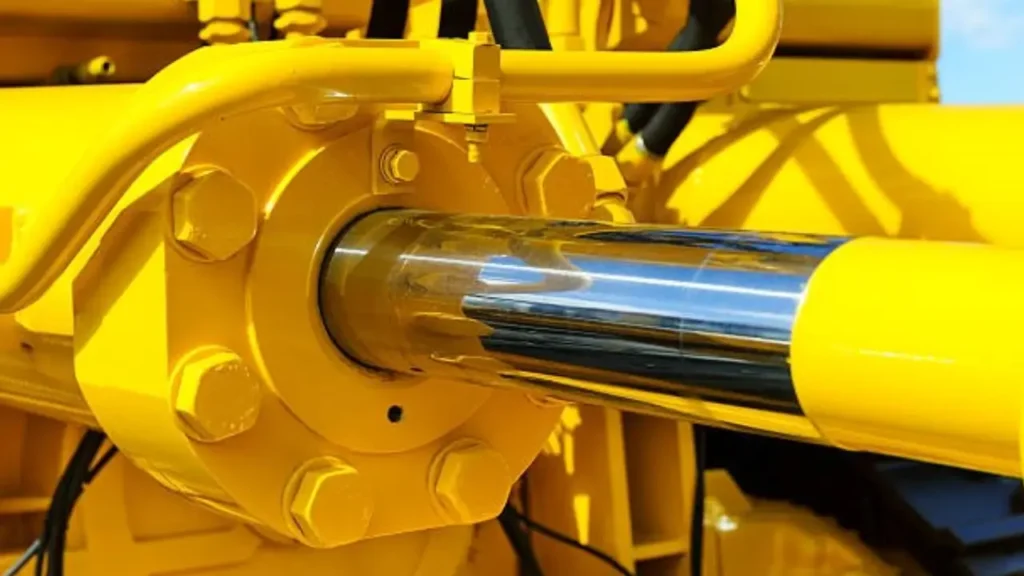

Step 3: Examine Cylinders and Actuators

We inspect hydraulic cylinders and actuators for leaks, dents, or unusual wear on rods and seals. Proper cylinder function is critical for consistent system performance and preventing sudden operational issues or failures.

We also check alignment and mounting points to avoid stress or bending on the cylinder components. Correct alignment reduces wear, ensures smooth movement, and maintains the efficiency of the hydraulic system under load.

Step 4: Test System Pressure

We measure hydraulic system pressure using appropriate gauges to confirm it meets manufacturer specifications. Low or high pressure may indicate pump issues, leaks, or blockages that can reduce system efficiency and cause component damage.

We also observe pressure fluctuations under load to detect irregular performance. Monitoring pressure ensures the system operates within safe limits, preventing overloading, excessive wear, and potential catastrophic failures during operation.

Step 5: Inspect Filters and Strainers

We examine hydraulic filters and strainers for dirt, debris, or clogging that may restrict fluid flow. Clean filters maintain fluid quality, prevent contamination, and ensure smooth operation of pumps, valves, and other hydraulic components.

We also replace or clean filters as needed according to maintenance schedules. Regular filter inspection reduces wear, prevents system damage, and prolongs the service life of critical hydraulic equipment.

Step 6: Check Valves and Control Components

We inspect directional, pressure, and flow control valves for proper operation, leaks, or sticking. Malfunctioning valves can cause erratic system behavior, reduced efficiency, or even damage to connected components if not addressed.

We also ensure control components, including levers and actuators, function smoothly without excessive force. Properly maintained valves and controls enhance operational safety, accuracy, and the overall reliability of the hydraulic system.

Step 7: Monitor Temperature and Noise

We check system temperature during operation to detect overheating, which can indicate excessive friction, fluid issues, or component malfunction. Maintaining the correct temperature prevents fluid degradation and reduces component wear.

We also listen for unusual noises, such as knocking or whining, which may signal cavitation, pump wear, or misalignment. Early detection allows prompt corrective action, ensuring safe and efficient hydraulic system performance.

Conclusion

You can significantly reduce the risk of unexpected failures, costly downtime, and potential safety hazards by diligently inspecting your hydraulic hoses for signs of wear and tear. Remember, a small investment in preventative maintenance can save you substantial costs in the long run.

Ready to upgrade your hydraulic system with top-quality hoses? Contact us today to explore our extensive range of wholesale hydraulic hoses. Our expert team is dedicated to providing you with reliable and durable solutions tailored to your specific needs.

Don’t compromise on the health of your hydraulic system. Choose [Your Company Name] for premium hydraulic hoses and expert advice.