Choosing the right hose is critical to system performance and safety. In demanding, high-pressure applications, the discussion often comes down to two key points: 4SP and 4SH hydraulic hoses. These are not random names, but rather unique engineering marvels designed to withstand specific levels of pressure and impulse, making their selection critical for both engineers and operators.

In this blog post, we’ll take a deep dive into the differences between 4SP and 4SH hydraulic hoses, their applications, and considerations when choosing one to help you make an informed decision for your next project.

What Do 4SP and 4SH Stand For?

Before we get into the nitty-gritty of their differences, let’s clarify what these abbreviations mean. Understanding the nomenclature is the first step in differentiating between 4SP vs 4SH hydraulic hoses.

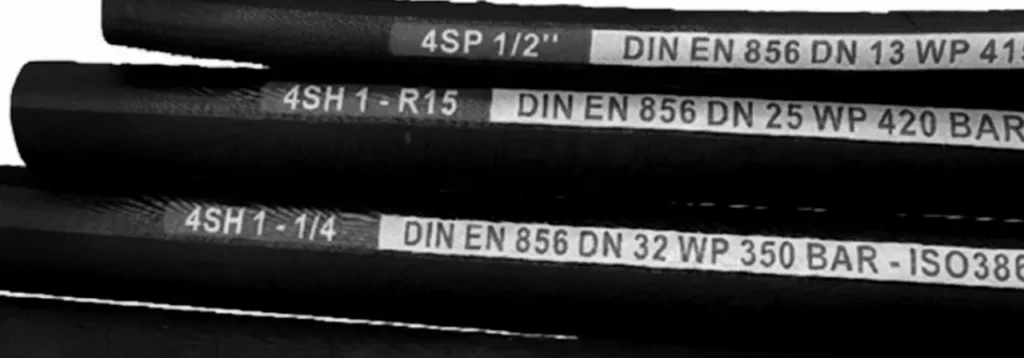

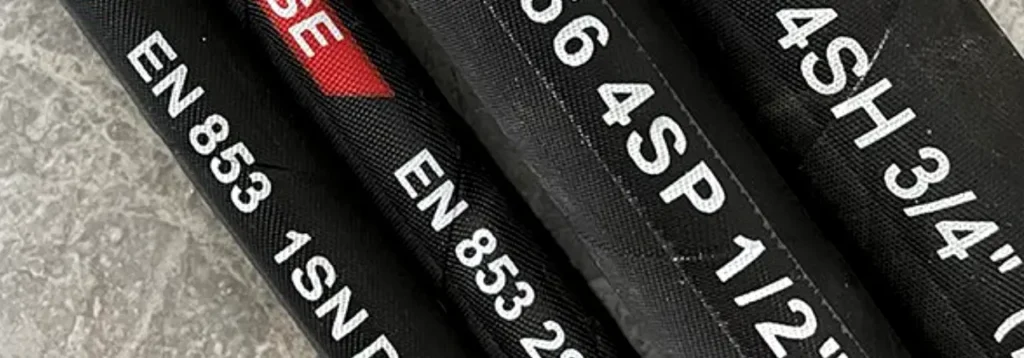

These designations come from the European Standard EN 856, which sets the guidelines for rubber hoses reinforced with spiral wire.

Decoding the EN 856 Standard

The EN 856 standard is a comprehensive guide to hydraulic rubber hoses. When we see “4SP” or “4SH”, the “4” clearly indicates that the hose is reinforced with four layers of high-strength steel wire spirals. This spiral reinforcement is essential for hoses that withstand high pressures and impulse cycles, and it performs better than braided reinforcement in certain harsh environments.

The primary difference between the two types lies in the “SP” and “SH” suffixes, which denote their expected pressure capabilities and structural nuances that impact their suitability for application and overall performance characteristics in various hydraulic systems.

Construction Differences: 4SP vs 4SH Hydraulic Hoses

The root cause of the difference in performance characteristics between 4SP and 4SH hydraulic hoses lies in their differences in construction. While both feature four layers of spiraled steel wire, the subtle and significant engineering design makes them stand out in terms of pressure rating, flexibility, and overall durability.

The Inner Workings of a 4SP Hose

The construction of a 4SP hydraulic hose typically includes an inner tube made of oil-resistant synthetic rubber to ensure compatibility with the fluid. Surrounding the outer tube are four layers of spiraled high-strength steel wire. These layers of steel wire are typically precisely wound in alternating directions to provide great strength and resistance to internal pressure.

The outer layer is typically made of abrasion-resistant and weather-resistant synthetic rubber, protecting the inner core from external damage. This design provides a good balance between pressure-bearing capacity and flexibility, making it suitable for a variety of heavy-duty applications.

The Rugged Construction of a 4SH Hose

In contrast, the 4SH hydraulic hose is designed for the highest pressure applications. While it also features four layers of spiraled high-strength steel wire, the key difference is usually the wire gauge or density of the spiral wrap. The wire used in 4SH hoses is typically heavier or more tightly wound, which increases burst pressure resistance and pulse fatigue life.

This makes the 4SH hose inherently stronger than the same-sized 4SP hose. Like the 4SP hose, it features an oil-resistant synthetic rubber inner tube and a rugged cover, but its reinforcement is specially designed to handle the most severe pressure spikes and sustained high-pressure service.

Performance Metrics: Pressure, Temperature, and Flexibility

Understanding the technical specifications of 4SP vs 4SH hydraulic hoses goes beyond just their construction. It involves a close look at their performance metrics, particularly their working pressure, temperature ranges, and relative flexibility. These factors are critical when I’m assessing which hose is the best fit for a client’s demanding hydraulic system.

Working Pressure and Burst Pressure

The most significant differentiator when comparing 4SP vs 4SH hydraulic hoses is their pressure rating. 4SH hoses are designed for higher working pressures than 4SP hoses of the same nominal bore. For instance, a 1-inch 4SH hose will generally have a higher maximum working pressure than a 1-inch 4SP hose. This is directly attributable to the heavier-duty wire or denser spiraling in the 4SH construction.

The burst pressure, which is the pressure at which the hose is expected to fail, is also proportionally higher for 4SH hoses, providing an increased safety margin in extreme conditions. This superior pressure handling is why 4SH hoses are often preferred for ultra-heavy machinery.

Temperature Range Considerations

While both 4SP vs 4SH hydraulic hoses are built for demanding environments, there can be subtle differences in their specified temperature ranges. Generally, both types are designed to operate within a wide temperature spectrum, typically from -40°C to +100°C (-40°F to +212°F) for their standard synthetic rubber compounds.

Some 4SP variants might offer a slightly higher maximum temperature rating (e.g., up to +125°C or +257°F) due to less material mass in their reinforcement, leading to less heat retention. It’s always crucial to check the specific manufacturer’s specifications for the exact temperature limits, as exceeding these can severely degrade hose performance and lifespan.

Flexibility and Bend Radius

The inherent trade-off with increased pressure rating is often reduced flexibility. When comparing 4SP vs 4SH hydraulic hoses, the 4SH hose, with its more robust spiral wire reinforcement, is generally less flexible and has a larger minimum bend radius than a 4SP hose of the same size. This is an important consideration during installation, especially in confined spaces or where tight routing is unavoidable.

While 4SP hoses offer a good balance of pressure resistance and flexibility, 4SH hoses prioritize ultimate strength. Understanding these flexibility differences helps avoid kinking or stressing the hose beyond its limits, which could lead to premature failure.

4SP vs 4SH Hydraulic Hoses Applications

Knowing the technical differences between 4SP vs 4SH hydraulic hoses is one thing; understanding where each excels in real-world applications is another. My experience has shown that selecting the right hose is about matching its capabilities to the specific demands and environment of the hydraulic system.

Applications for 4SP Hydraulic Hoses

We often recommend 4SP hydraulic hoses for applications that demand high pressure but aren’t necessarily subjected to constant, extreme pressure spikes. Their balance of strength and flexibility makes them incredibly versatile. Common applications include:

- Medium-Duty Construction Equipment: Such as excavators, loaders, and dozers, where they handle main hydraulic lines for boom, bucket, and track movements.

- Agricultural Machinery: Used in combines, tractors, and other heavy-duty farm equipment for various hydraulic functions.

- General Industrial Hydraulics: Found in manufacturing plants, presses, and large stationary machinery requiring reliable high-pressure fluid transfer.

- Forestry Equipment: Operating in challenging outdoor conditions, these hoses are used in log skidders and harvesters.

The 4SP hose provides excellent performance in these settings, offering durability and a manageable bend radius for installation.

Applications for 4SH Hydraulic Hoses

When the pressure is truly on, figuratively and literally, that’s when I turn to 4SH hydraulic hoses. These are built for the most arduous conditions, where consistent extreme pressure and high impulse cycles are the norm. Their primary applications include:

- Ultra-Heavy Construction and Mining Equipment: Think massive excavators, large dump trucks, and underground mining machinery, where hydraulic systems operate under immense loads and constant pressure fluctuations.

- High-Impulse Systems: Applications where pressure spikes are frequent and severe, requiring a hose with superior fatigue resistance.

- Large Industrial Hydraulic Systems: Such as forging presses, metal forming machinery, and other applications that generate extreme hydraulic forces.

- Offshore and Marine Equipment: Used in harsh environments where reliability under very high pressure is critical for safety and operation.

The robust nature of the 4SH hose ensures longevity and safety in these incredibly demanding scenarios.

How to Choose 4SP vs 4SH Hydraulic Hoses

| Feature | EN 856 4SP Hydraulic Hose | EN 856 4SH Hydraulic Hose |

| Reinforcement | 4 layers of high-tensile steel wire spirals | 4 layers of high-tensile steel wire spirals (often heavier gauge/denser) |

| Pressure Rating | High pressure (e.g., 250-450 bar for various sizes) | Very high pressure (e.g., 280-500 bar for various sizes, higher than 4SP for same ID) |

| Flexibility | Good, more flexible than 4SH | Less flexible, larger minimum bend radius |

| Impulse Life | Very good | Excellent, superior for extreme impulse |

| Typical Use | General heavy-duty construction, agriculture, industrial applications | Ultra-heavy construction, mining, extreme high-pressure industrial systems |

| Cost | Generally more cost-effective | Higher cost due to robust construction |

| Temperature | Typically -40°C to +100°C (some up to +125°C) | Typically -40°C to +100°C |

How to Choose 4SP and 4SH Hydraulic Hoses?

Selecting the right 4SP or 4SH hydraulic hoses is essential for high-pressure applications. These hoses differ in construction, flexibility, and operating pressure. Understanding their specifications ensures safe, efficient fluid transfer and prolongs equipment life, minimizing downtime and maintenance issues.

- Pressure Rating: 4SP hoses are designed for medium pressure, while 4SH handles higher pressure demands. Choosing according to system requirements prevents hose failure and ensures safety. Accurate pressure matching protects both the hose and connected equipment.

- Construction: 4SP hoses have textile-reinforced layers, whereas 4SH hoses use multiple steel wire braids. Steel-reinforced hoses provide superior strength, durability, and resistance to wear, making them ideal for heavy-duty machinery and harsh operating environments.

- Flexibility & Application: 4SP hoses are more flexible, suitable for tight bends and mobile equipment. 4SH hoses are less flexible but perfect for high-pressure industrial systems. Selecting based on the application ensures optimal performance, efficiency, and longevity of the hydraulic system.

Conclusion

Comparing 4SP and 4SH hydraulic hoses, the core difference lies in their pressure resistance and rugged construction.

Both feature four layers of spiral wire, but the 4SH hose features thicker wire or more dense windings, allowing it to withstand much higher operating pressures and more extreme pressure pulses than the 4SP hose.

4SP offers a good balance between high pressure and flexibility for general heavy-duty applications, while 4SH prioritizes maximum strength and durability for the toughest, high-pulse environments. For more information, please contact us.