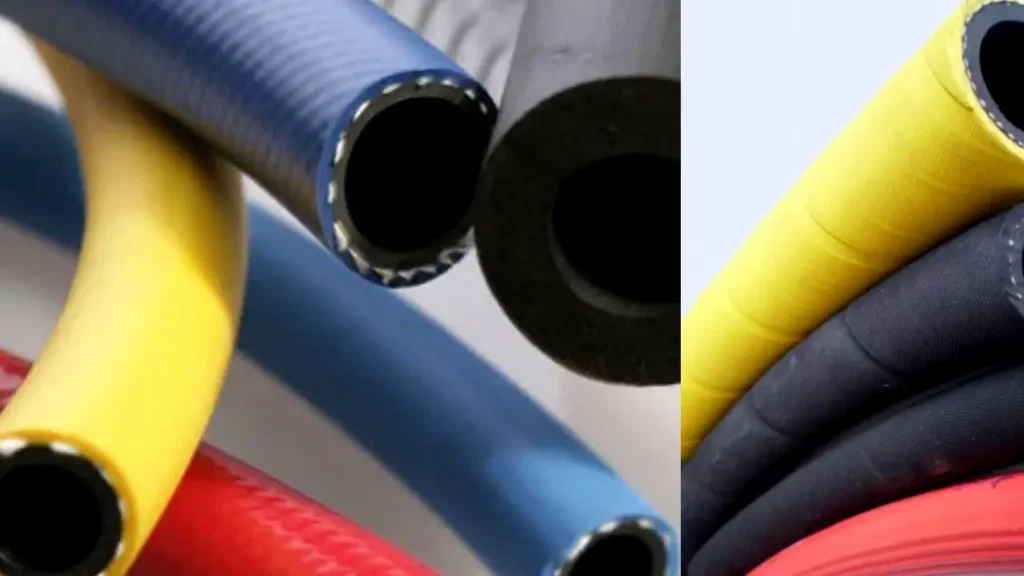

Rubber hoses are ubiquitous in modern life, serving as the crucial, flexible arteries that transport fluids and gases across countless applications. From the simple garden hose watering your plants to the high-pressure lines powering heavy machinery, these versatile components are essential for operational efficiency. Understanding what a rubber hose is, how it’s constructed, and its different varieties is key to selecting the right one for any job.

Despite their simple appearance, rubber hoses are engineered products designed to withstand specific pressures, temperatures, and chemical exposures. This ultimate guide will take you on a deep dive into the world of flexible piping, explaining the various types (like hydraulic, air, and water hoses), the materials that make them up, their core functions, and indispensable tips for proper selection and long-term maintenance.

What are Rubber Hoses?

A rubber hose is essentially a flexible, hollow tube designed to transport fluids, gases, or even fluidized solids from one point to another within a system. Made from either natural or various synthetic rubber compounds (like EPDM, Nitrile, or Silicone), their core function is to maintain an efficient, leak-free connection, often connecting rigid components like pumps and valves. The flexibility of rubber is key, allowing the hose to absorb vibrations, accommodate misalignments, and bend around corners where rigid piping cannot.

The construction of most rubber hoses is multilayered to ensure strength and durability. The innermost layer, or tube, is chemically resistant to the fluid being conveyed. This is surrounded by a reinforcement layer—typically braided, spiral, or woven fibers or wire—which provides the necessary pressure resistance to prevent bursting or collapsing. Finally, the cover is the outermost protective shield, guarding the hose against external damage, abrasion, weathering, and ozone exposure for long-lasting performance.

What are Rubber Hoses Made of?

A rubber hose is a complex, engineered assembly, not a simple piece of tubing. To ensure performance, durability, and safety, it is constructed in distinct layers, with the specific rubber compound chosen based on the fluid, temperature, and environment of its intended application.

Inner Tube Materials

- Nitrile (NBR): Nitrile is a synthetic rubber favored for its exceptional resistance to petroleum products, including oil, gasoline, and hydraulic fluids. This makes it an ideal, non-swelling liner material for fuel lines and high-pressure hydraulic hoses in various industrial equipment.

- EPDM (Ethylene Propylene Diene Monomer): EPDM offers superb resilience against weathering, ozone, steam, and high-heat water. It’s primarily chosen for outdoor applications, automotive cooling systems (radiator hoses), and industrial lines carrying hot water, due to its reliable thermal stability.

- Natural Rubber (NR): Derived from latex, natural rubber is unmatched in its elasticity and resistance to abrasion. This resilience makes it the material of choice for the inner tube in hoses transporting highly abrasive materials like sand, gravel, cement, or mining slurry.

Reinforcement Layer Materials

- Textile (Fibers): Reinforcement layers using braided or spiraled polyester, rayon, or synthetic fibers provide the structural integrity for low-to-medium pressure applications. These layers are cost-effective, offer good flexibility, and prevent the hose from kinking under normal operating conditions.

- Steel Wire: High-pressure hydraulic and steam hoses require layers of braided or spiral-wound steel wire. This metallic reinforcement is crucial for maintaining the hose’s form and ensuring it can safely withstand the extreme high impulse pressures common in heavy machinery and demanding industrial systems.

Outer Cover Materials

- Neoprene (CR): The outer cover of Neoprene is a balanced compound providing resistance against moderate oil exposure, flame, and general wear. It’s a versatile and cost-effective choice for general-purpose hoses that may encounter mild industrial chemicals or external grime.

- Synthetic Rubber Blends: Manufacturers use specialized synthetic blends, often incorporating EPDM or SBR, to create covers with exceptional abrasion, ozone, and UV resistance. These blends protect the inner layers from cutting, scraping, or cracking when the hose is routinely dragged across harsh factory floors or construction sites.

Types of Rubber Hoses

Rubber hoses are not one-size-fits-all; they are meticulously categorized and engineered to handle specific media and operational demands. The material of the tube, the type of reinforcement, and the thickness of the cover all determine a hose’s suitability for a given task. Here are the primary types you will encounter in industrial and commercial settings, each designed for a unique application environment.

Hydraulic Rubber Hoses

Hydraulic Rubber Hoses are among the most robust types, specifically engineered to transmit power in fluid-based systems by carrying highly pressurized hydraulic fluid, typically oil. Found extensively in heavy machinery, construction equipment, and manufacturing plants, these hoses feature heavy-duty wire braiding or spiral-wrapped reinforcement layers to withstand extreme internal pressures, ensuring the reliable operation of cylinders, motors, and other hydraulic components.

Air and Pneumatic Rubber Hoses

Designed to convey compressed air from a source, such as a compressor, to a tool or system, Air and Pneumatic Rubber Hoses are essential in workshops, construction sites, and assembly lines. These hoses require high burst pressure ratings and excellent abrasion resistance since they are often dragged across rough floors. Materials like EPDM or PVC/rubber blends are common, offering a balance of flexibility for easy handling and sufficient strength for the consistent delivery of pressurized air.

Water and Coolant Rubber Hoses

Water and Coolant Rubber Hoses are generally designed for lower pressure applications compared to hydraulic lines, focusing instead on chemical and temperature compatibility. Automotive cooling systems rely on molded rubber hoses to carry hot coolant, requiring resistance to heat and antifreeze chemicals. General water transfer hoses, used for washdown or irrigation, prioritize flexibility and resistance to weathering and kinking, often utilizing durable rubber compounds like EPDM or SBR.

Material Handling Rubber Hoses

Material Handling Rubber Hoses are built to transfer abrasive media, including dry bulk solids like grain, sand, cement, or slurries. The key feature of this type is an exceptionally thick and wear-resistant inner tube to prevent rapid deterioration from friction. These hoses are used extensively in mining, agriculture, and chemical industries, designed to be robust enough to withstand the continuous punishment of conveying heavy, abrasive materials over long distances.

Chemical Rubber Hoses

Used to safely transfer a broad spectrum of corrosive acids, solvents, and chemicals, Chemical Rubber Hoses feature specialized inner tube materials—often highly engineered synthetic rubbers or polymers—selected for their inertness and non-reactivity with the transported substance. The stringent safety requirements for these applications necessitate a hose that can maintain its integrity and prevent leakage under various concentrations and temperatures, protecting both personnel and the environment.

Suction and Discharge Rubber Hoses

Suction and Discharge Rubber Hoses are dual-purpose lines designed to operate under both negative pressure (suction) to draw in fluids and positive pressure (discharge) to push them out. These hoses are often reinforced with a helical wire embedded in the hose wall to prevent collapse under vacuum conditions, making them ideal for applications like dewatering, waste removal, and tanker loading/unloading where fluid is both pulled and pushed.

Steam Rubber Hoses

Steam Rubber Hoses are highly specialized for safely conveying saturated and superheated steam in industrial cleaning, heating, and processing applications. Due to the extreme temperatures involved, these hoses utilize high-grade synthetic rubber compounds like EPDM in the inner tube and cover, which offer superior heat resistance. They also incorporate multiple layers of high-tensile reinforcement to handle the high pressures associated with steam systems.

Food-Grade Rubber Hoses

Food-Grade Rubber Hoses are designed specifically for the food, beverage, and pharmaceutical industries, adhering to strict sanitary standards (such as FDA approval). Their inner tubes are non-toxic, tasteless, and odorless to prevent contamination of edible products. These hoses often feature smooth inner bores for easy cleaning and sterilization (CIP/SIP) and are resistant to common cleaning chemicals and high washdown temperatures.

How Long Do Rubber Hoses Last?

The operational lifespan of a rubber hose varies drastically, ranging from a few months in severe industrial applications to over a decade in mild use scenarios. While a general guideline for many industrial and automotive rubber hoses is approximately 4 to 8 years, this figure is heavily influenced by several critical factors, primarily relating to the conditions of use and environmental exposure. Understanding these variables is key to setting an effective replacement schedule and preventing costly, unexpected failures.

- Temperature and Pressure: Extreme operating temperatures, both ambient and media-related, accelerate the degradation of the rubber polymers, causing them to harden and crack sooner. High pressure and frequent pressure spikes constantly stress the reinforcement layers, greatly shortening the hose’s effective service life.

- Media and Chemical Compatibility: The type of fluid or gas being transferred must be perfectly matched to the hose’s inner tube material (e.g., Nitrile for oil, EPDM for coolant). Using an incompatible medium causes the rubber to swell, soften, or dissolve, leading to premature failure and potentially dangerous leaks.

- Environmental Exposure and Abrasion: Outdoor hoses are constantly degraded by UV light and ozone, which cause the outer cover to crack (ozone checking). Hoses subjected to physical dragging, crushing, or rubbing against machinery quickly lose the protective integrity of their cover and reinforcement.

- Manufacturing Quality and Material: The inherent quality of the rubber compounds, the strength of the reinforcement, and the precision of the manufacturing process (including the proper crimping of fittings) are fundamental. Higher-quality hoses and those made from durable synthetics like Silicone or EPDM generally offer a longer service life.

How to Choose Suitable Rubber Hoses?

Selecting the correct rubber hose is a critical process that directly impacts operational safety, efficiency, and system longevity. Misapplication can lead to premature wear, costly failures, and potential environmental hazards. Industry experts simplify this complex decision using the mnemonic S.T.A.M.P.E.D., which outlines the seven vital criteria that must be evaluated for every hose assembly.

- S – Size (ID, OD, and Length): The inner diameter (ID) determines the flow rate and velocity of the media; an undersized ID creates excessive pressure drop and heat. You must also specify the correct overall length and outside diameter (OD) to ensure proper routing and prevent kinking or abrasion.

- T – Temperature (Media and Ambient): The hose must be rated to handle the maximum and minimum temperatures of the conveyed substance and the surrounding environment. Exceeding a hose’s temperature limit, especially with steam or hot fluids, quickly degrades the rubber polymer and drastically shortens its lifespan.

- A – Application (Conditions of Use): This refers to how the hose is actually used. Considerations include the minimum required bend radius, whether the pressure is static or dynamic (impulse/shock), and if the hose is subjected to severe external abuse, such as constant dragging or crushing forces.

- M – Media (Type of Substance): Chemical compatibility is paramount. You must identify the exact substance (oil, acid, air, slurry), its concentration, and state (liquid, gas, abrasive solid). The inner tube and fittings must be chemically inert to the media to prevent degradation, swelling, or contamination.

- P – Pressure (Working and Surge): The hose’s published maximum working pressure (MWP) must be equal to or greater than the maximum system pressure, including any momentary pressure spikes (surges). For applications involving vacuum, the hose must be reinforced to prevent the inner wall from collapsing.

- E – Ends (Fittings and Connections): The required end style (e.g., flange, camlock, threaded), material, and method of attachment (crimped or clamped) must be specified. The fittings must be compatible with both the hose material and the conveyed media to ensure a secure, leak-free, and pressure-rated connection.

- D – Delivery (Volume and Requirements): This refers to the volume of flow (GPM) and whether any special testing, certification, or packaging is required. Understanding the delivery needs helps confirm the inner diameter is correct for flow rate and ensures the hose assembly meets all regulatory and safety standards.

Conclusion

We’ve thoroughly explored the complex world of the rubber hose, demonstrating that it is far more than just a flexible tube. It is an expertly engineered component whose multilayered construction, material composition, and specific end-fittings are precisely tailored to handle rigorous demands across diverse industries, from automotive and manufacturing to construction and agriculture. Recognizing the subtle but significant differences between a hydraulic line and a simple water hose is critical for safety and efficiency.

The durability and performance of your operation are directly tied to the quality of the rubber hoses you employ. Investing in robust, properly rated hoses ensures maximum uptime, minimizes the risk of catastrophic failure, and secures the integrity of your fluid and gas transfer systems. Always verify that your chosen hose meets or exceeds the industry standards and pressure ratings for its intended application.

For all your wholesale rubber hose needs, look no further than our trusted expertise. At Gushan Rubber, we offer a comprehensive catalog of high-quality, certified rubber hoses designed to meet the toughest specifications. Whether you need standard industrial hoses or custom-engineered hydraulic lines, get wholesale rubber hoses from our Gushan Rubber to guarantee reliability and performance for your business.