When it comes to hydraulic hoses, there’s a vast array of types designed for different pressures, applications, and environments. Among the most common and versatile is the 2 wire hydraulic hose. But what is 2 wire hydraulic hose, and why is it so widely used across various industries, from construction to agriculture?

In this comprehensive guide, we’ll explore its construction, key characteristics, common applications, and why understanding its capabilities is crucial for anyone working with hydraulic systems.

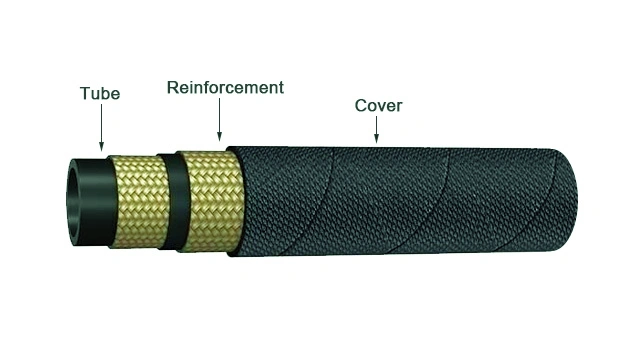

2-Wire Hydraulic Hose Structure

Unlike other hose types that might feature textile braids or spiraled wires, the defining characteristic of a 2 wire hydraulic hose lies in its reinforcement.

This specific design allows it to handle significant pressure while maintaining a good balance of flexibility and durability, making it a go-to choice for many medium to high-pressure hydraulic applications.

- Inner Tube: This innermost layer is made from a synthetic rubber material, such as nitrile or similar elastomers, chosen for its compatibility with various hydraulic fluids (petroleum-based, water-based, or synthetic). Its primary role is to ensure a leak-proof path for the fluid and to resist chemical degradation.

- Reinforcement Layers: This is where the “2 wire” comes into play. Immediately surrounding the inner tube are two braids of high-tensile steel wire. These layers are meticulously woven in opposing directions, providing the necessary strength to withstand the high internal pressures of hydraulic systems. This double-braided design offers excellent pressure containment without making the hose overly rigid.

- Outer Cover: The outermost layer is typically made from a synthetic rubber compound, like chloroprene or SBR, which is engineered to protect the reinforcement from external damage. This cover is designed to resist abrasion, ozone, UV radiation, oil, and various weather conditions, ensuring the hose’s longevity in harsh operating environments.

Key Characteristics of 2-Wire Hydraulic Hose

When evaluating the performance of dual-wire hydraulic hose, we discovered several outstanding characteristics that make it a top choice for many applications. These attributes contribute directly to its versatility and reliability in demanding hydraulic applications. Understanding these characteristics helps us make informed decisions when selecting the right hose for your equipment.

- Pressure Rating: 2-wire hydraulic hoses are designed for medium to high-pressure applications. While specific pressure ratings vary based on the hose’s inner diameter (ID) and manufacturer specifications, they typically comply with industry standards such as SAE 100R2 or EN 853 2SN. This makes them suitable for a wide range of machinery where consistent pressure delivery is crucial.

- Flexibility: Despite their robust steel wire reinforcement, 2-wire hoses offer a good degree of flexibility compared to multi-spiral hose types. This allows for easier routing in complex machinery and better absorption of system vibrations, reducing stress on fittings and other components.

- Durability: The double-braided steel wire provides excellent resistance to burst pressures and fatigue from impulse cycles. Coupled with a durable outer cover, these hoses are built to withstand tough operating conditions, including exposure to elements, chemicals, and physical abrasion.

- Temperature Range: Most 2-wire hydraulic hoses are designed to operate within a broad temperature range, typically from -40°F to +212°F (-40°C to +100°C) for petroleum-based fluids. This wide range ensures their reliability in various climates and operational environments.

- Fluid Compatibility: The inner tube material is selected for its broad compatibility with common hydraulic fluids, including mineral oils, water-glycol, and some synthetic esters. Always verify specific fluid compatibility with the manufacturer’s data sheet for critical applications.

- Compliance with Standards: 2-wire hydraulic hoses commonly adhere to international standards like SAE 100R2 and EN 853 2SN. These standards ensure consistent quality, performance, and interchangeability across different manufacturers. When we specify a hose, we always ensure it meets the required certifications.

2-Wire Hydraulic Hose Applications

The versatility and robustness of Duplex Hydraulic Hose make it an indispensable material in numerous industries and machinery. When asked about the uses of Duplex Hydraulic Hose, we can name almost any equipment that relies on hydraulic power.

- Construction Equipment: This includes excavators, bulldozers, loaders, backhoes, and cranes. The hydraulic systems in these machines operate under significant pressure and require hoses that can withstand heavy use, abrasion, and exposure to dirt, debris, and extreme weather. 2 wire hydraulic hose is ideal for boom cylinders, bucket controls, and steering systems.

- Agricultural Machinery: Tractors, combines, planters, and other farm equipment rely heavily on hydraulics for implements like plows, cultivators, and loaders. 2 wire hose provides the necessary strength and flexibility for these intermittent but demanding applications.

- Material Handling: Forklifts, telehandlers, and other lifting equipment use hydraulics for raising and lowering loads. The hoses in these applications need to handle regular pressure cycles and provide consistent performance.

- Industrial Equipment: Many factory and manufacturing processes utilize hydraulic systems for pressing, clamping, cutting, and conveying. This can include anything from hydraulic presses to automated assembly lines. 2 wire hydraulic hose offers the durability required for continuous operation.

- Forestry Equipment: Log splitters, feller bunchers, and other logging machinery operate in rugged, abrasive environments. Hoses here need to be extremely durable and capable of handling high pressures associated with powerful cutting and gripping tools.

- Mining: In mining operations, equipment like drills, longwall miners, and roof supports depend on robust hydraulic systems. The harsh conditions in mines demand hoses that can withstand extreme pressures, constant abrasion, and often corrosive fluids.

- Trucking and Transportation: While not always the primary hydraulic system, many commercial vehicles use hydraulics for dump beds, power steering, and braking systems. 2 wire hose provides the reliability needed for road transport applications.

2 Wire Hydraulic Hose vs Other Hose Types

While dual-line hydraulic hoses are versatile, they aren’t always the best choice. We often compare them to other common constructions to help you choose the best hose for your specific application.

1 Wire Hydraulic Hose (SAE 100R1 / EN 853 1SN)

- Reinforcement: Single braid of steel wire.

- Pressure Rating: Lower than 2 wire hoses, suitable for low to medium-pressure applications.

- Flexibility: Generally more flexible and lighter than 2 wire hoses due to less reinforcement.

- Cost: Typically less expensive than 2 wire hose.

- Our Use: We recommend 1 wire hose for return lines, pilot lines, and other lower-pressure circuits where space or weight is a primary concern.

Multi-Spiral Hydraulic Hose (e.g., SAE 100R12, 100R13 / EN 856 4SP, 4SH)

- Reinforcement: Multiple (4 or 6) layers of spiraled high-tensile steel wire.

- Pressure Rating: Designed for extremely high and ultra-high pressure applications.

- Flexibility: Less flexible and heavier than 2-wire hoses due to more reinforcement.

- Cost: Significantly more expensive.

- Our Use: We specify multi-spiral hoses for very demanding applications like heavy construction machinery, large presses, and drilling rigs where continuous high pressure and pressure surges are expected. They offer superior performance in these extreme environments.

Textile Braided Hose (e.g., SAE 100R3, 100R6)

- Reinforcement: Textile (fiber) braid, not wire.

- Pressure Rating: Low pressure only.

- Flexibility: Very flexible and lightweight.

- Cost: Least expensive.

- Our Use: Primarily for very low-pressure applications, suction lines, or return lines where high flexibility and low cost are critical, and pressure is not a significant factor.

| Feature | 1 Wire Hose | 2 Wire Hose | Multi-Spiral Hose | Textile Braided Hose |

| Reinforcement | 1 Steel Wire Braid | 2 Steel Wire Braids | 4 or 6 Spiral Wire Layers | Textile Braid |

| Pressure | Low to Medium | Medium to High | High to Ultra-High | Low |

| Flexibility | Very Good | Good | Moderate | Excellent |

| Weight | Light | Medium | Heavy | Very Light |

| Cost | Low | Medium | High | Very Low |

| Typical Use | Return lines, Pilot | Construction, Industrial | Heavy Duty, Extreme Pr. | Suction, Low Pressure |

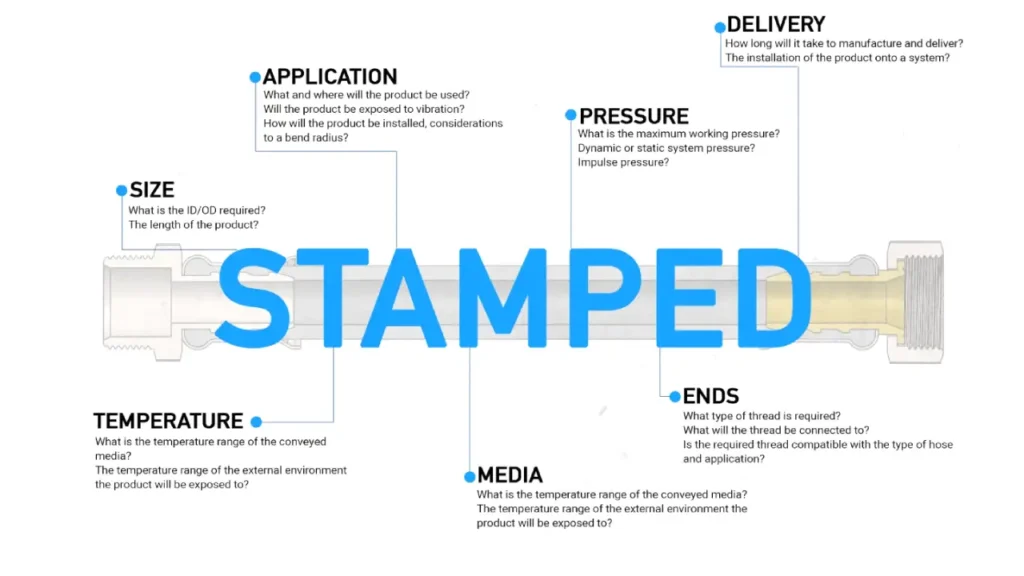

How to Choose the Right Hydraulic Hoses

Choosing the correct hydraulic hose is critical for the safety and efficiency of your fluid power system. A simple method, often remembered by the acronym STAMPED, guides the selection process by considering seven key factors for every application, ensuring optimal performance and longevity.

- Size (S): The Inner Diameter (I.D.) must be adequate for the required flow rate. If the I.D. is too small, flow restrictions cause a pressure drop and generate excessive heat, which can damage the hose and reduce system efficiency. Length is also key; too long increases pressure drop, while too short can cause strain.

- Temperature (T): You must account for both the maximum fluid temperature and the ambient operating temperature. Hoses have specific maximum temperature ratings, and exceeding them will rapidly degrade the materials. Check if the hose’s temperature rating is compatible with the fluid type for safe, long-term operation.

- Application (A): The hose must be suitable for the machine and its operating environment. This includes checking for required industry standards (SAE, ISO), the minimum bend radius to prevent kinking or stress, and external factors like abrasion, vibration, or potential chemical exposure on the cover.

- Material (M): The hose’s inner tube and cover materials must be chemically compatible with the fluid being conveyed. Incompatible materials will lead to deterioration of the hose’s interior tube or cover, causing swelling, leaks, and eventual catastrophic failure of the hose assembly.

- Pressure (P): The hose’s maximum working pressure must be equal to or greater than the maximum system pressure, including any high-pressure spikes or surges (impulse pressure). For safety, the burst pressure rating is often four times the working pressure. Do not mix components with different ratings.

- Ends or Couplings (E): The fittings and couplings must be physically and pressure-rated for the specific hose and application. Improperly matched or crimped fittings are a leading cause of hydraulic hose failure. Always use components designed to work together to ensure a secure, leak-free connection.

- Delivery (D): This factor primarily relates to flow volume and velocity through the hose, which ties back into the size selection (I.D.). It also refers to the availability and lead time of the required hose assembly components for maintenance and replacement needs.

Conclusion

Understanding the structure, performance, and typical applications of dual-line hydraulic hoses enables us to make informed decisions, ensuring the efficiency, safety, and longevity of our hydraulic systems.

Are you developing a hydraulic system and considering dual-line hydraulic hoses? Please let us know your specific application requirements; we’ll be happy to help you make the best choice!