Skiving hydraulic hoses is a crucial process in ensuring secure and reliable connections in high-pressure hydraulic systems. This technique involves removing the outer cover, and sometimes the inner tube, of a hydraulic hose before attaching the fittings. Proper skiving creates a direct metal-to-metal contact, vital for preventing leaks and maintaining system integrity in demanding applications.

This blog post will delve into the step-by-step process of skiving hydraulic hoses, outlining the necessary tools and techniques. We’ll explore the importance of precise measurements and consistent execution to achieve optimal results, ensuring your hydraulic systems operate safely and efficiently.

What Is Hydraulic Hose Skiving

Hydraulic hose skiving is the process of removing a portion of the outer cover, and sometimes the inner tube, of a hydraulic hose before attaching fittings. This preparation is essential for creating a secure, metal-to-metal connection between the fitting and the hose’s reinforcement layers, typically steel wire braids. This direct contact ensures a robust seal, particularly crucial in high-pressure hydraulic systems where leaks can lead to significant operational issues and safety hazards.

The hydraulic hose skiving process allows the fitting to grip the reinforcement layers directly, preventing the hose from slipping or the fitting from detaching under extreme pressure. By removing the cover, the fitting can achieve a more reliable mechanical connection, enhancing the overall integrity and longevity of the hydraulic system. Skiving is a critical step in assembling high-performance hydraulic hoses, ensuring they can withstand the rigorous demands of their applications.

How to Skive Hydraulic Hoses

Skiving hydraulic hoses is a crucial process for ensuring reliable, leak-free connections in high-pressure hydraulic systems. Proper skiving techniques are essential for creating a strong bond between the hydraulic hose and fitting, preventing premature failures and maintaining system integrity. Here’s a step-by-step guide on how to skive hydraulic hoses:

Step 1. Measure and Mark the Hydraulic Hose

Before skiving, accurately measure the length of hydraulic hose cover that needs to be removed. Consult the fitting manufacturer’s specifications for the required skive length. Use a measuring tape or ruler and mark the hydraulic hose clearly with a marker or tape. Ensure the mark is perpendicular to the hydraulic hose axis to create a clean, even skive.

Accurate measurements are critical for a proper fit. An incorrect skive length can result in leaks or fitting failures. Double-check your measurements and markings before proceeding. Precision at this stage prevents costly errors and ensures the integrity of the hydraulic connection.

Step 2. Secure the Hydraulic Hose

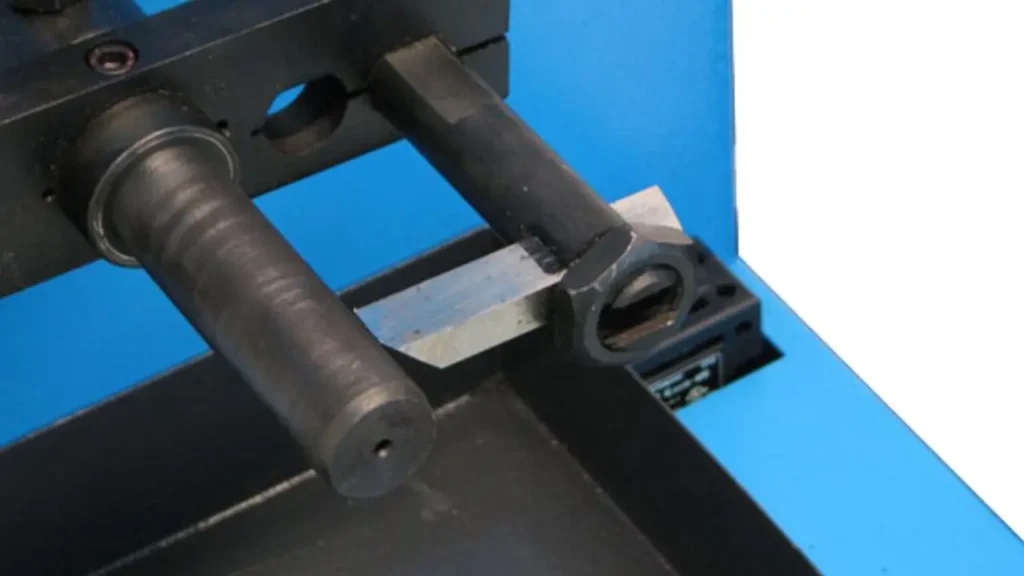

Secure the hydraulic hose firmly in a vise or hydraulic hose skiving machine. Ensure the hydraulic hose is held tightly to prevent movement during the skiving process. A stable hydraulic hose is essential for achieving a clean and accurate skive. Use soft jaws or protective covers on the vise to avoid damaging the hydraulic hose reinforcement layers.

Properly securing the hydraulic hose is vital for safety and precision. An unsecured hydraulic hose can move during skiving, leading to uneven cuts and potential injury. Use a skiving machine when available, as it provides consistent and accurate results.

Step 3. Use the Skiving Tool

Insert the skiving tool into the hydraulic hose end, aligning it with the marked line. Follow the tool manufacturer’s instructions for adjusting the cutting depth. Slowly rotate the tool, applying even pressure to remove the hydraulic hose cover. Maintain a consistent speed and pressure to ensure a uniform skive.

The choice of skiving tool depends on the hydraulic hose size and type. Select a tool designed for the specific hydraulic hose material and reinforcement. Incorrect tool usage can damage the hydraulic hose or create an uneven skive.

Step 4. Remove Skived Material and Inspect

Once the cover is removed, carefully remove any loose debris or rubber particles from the skived area. Inspect the exposed reinforcement layers for any damage or irregularities. Ensure the skive is clean and even, with no frayed edges or tears.

A clean skive is essential for a proper seal. Any debris or damage can compromise the connection and lead to leaks. If any damage is found, cut the hydraulic hose back and repeat the skiving process.

Step 5. Attach the Fitting

Insert the fitting into the skived hydraulic hose end, ensuring it is fully seated against the reinforcement layers. Follow the fitting manufacturer’s instructions for assembly and tightening. Use the appropriate tools and torque specifications to secure the fitting.

Proper fitting installation is critical for a leak-free connection. Ensure the fitting is correctly aligned and torqued to prevent leaks and ensure the hydraulic system’s reliability.

Why Skiving Hydraulic Hoses

Skiving hydraulic hoses is essential for creating secure and reliable connections, particularly in high-pressure hydraulic systems. This process involves removing a portion of the outer cover (and sometimes the inner tube) to allow the fitting to directly contact the hydraulic hose’s reinforcement layers. This direct contact ensures a robust mechanical connection, minimizing the risk of leaks and fitting detachment under extreme pressure.

Key reasons for skiving include:

- Enhanced Sealing: Metal-to-metal contact creates a superior seal, preventing fluid leaks.

- Improved Fitting Retention: Direct contact with reinforcement layers reduces the chance of fitting slippage or detachment.

- Increased System Integrity: Ensures the hydraulic system can withstand high pressures and demanding operating conditions.

- Longer Hydraulic Hose Lifespan: Proper skiving prevents premature hydraulic hose failure by creating a strong connection.

Skive Hydraulic Hose vs Non Skive Hydraulic Hose

Skive hydraulic hoses require the removal of the outer cover, and sometimes the inner tube, before fittings are attached. This process creates a direct metal-to-metal contact between the fitting and the hydraulic hose’s reinforcement layers, ensuring a highly secure connection. This is crucial for high-pressure applications where leaks are unacceptable.

- High-Pressure Applications: Ideal for systems operating under extreme pressure.

- Enhanced Sealing: Metal-to-metal contact provides a superior seal.

- Robust Connection: Minimizes the risk of fitting slippage or detachment.

Non-skive hydraulic hoses eliminate the need for skiving, simplifying the assembly process. The fittings are designed to grip the hydraulic hose directly, reducing labor time and costs. These hoses are commonly used in medium to lower pressure systems where ease of installation is a priority.

- Simplified Assembly: No need for skiving, reducing labor.

- Faster Installation: Fittings grip the hydraulic hose directly.

- Medium to Lower Pressure: Suitable for less demanding applications.

Conclusion

Mastering the skiving process is vital for ensuring reliable high-pressure hydraulic connections. Proper skiving, including accurate measurements and precise cover removal, prevents leaks and extends hose lifespan. Incorrect skiving can lead to premature failure, compromising system integrity.

Understanding the tools and techniques involved is crucial for any technician working with hydraulic systems. Practice and attention to detail are key to achieving consistent, high-quality skives.

For top-tier wholesale hydraulic hoses, including those designed for optimal skiving, contact Gushan Rubber. We provide a wide range of durable and reliable hoses to meet your specific needs. Get a quote today and experience the Gushan Rubber advantage.