Ptfe Braided Hose

A PTFE braided hose is a premium fluid transfer solution built for the most demanding applications. At its core is a polytetrafluoroethylene (PTFE) inner tube, a material celebrated for its extreme chemical resistance and ability to withstand high temperatures. This core is then fortified with a braided outer layer, typically made from high-tensile stainless steel. This reinforcement provides exceptional durability, protecting the hose from external damage and high pressures compromising flexibility. It is an indispensable component in industries such as automotive, aerospace, and chemical manufacturing, where safety and reliability are paramount.

Get Your Desired Ptfe Braided Hose

PTFE braided hose is a top-tier fluid transfer solution. Its PTFE core offers unmatched chemical and temperature resistance, while the stainless steel braid provides superior pressure and abrasion protection. Ideal for demanding applications, this hose ensures safety and long-lasting performance.

All Ptfe Braided Hoses

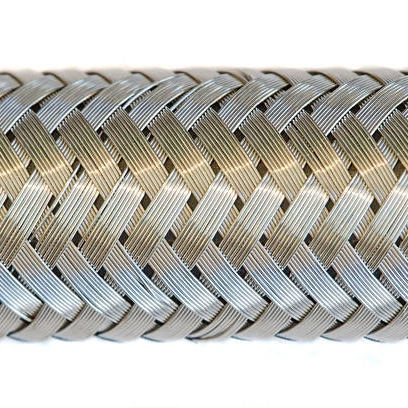

PTFE Stainless Steel Braided Hose

PTFE stainless steel braided hose represents the gold standard for high-performance fluid transfer. The hose core is a smooth, non-reactive PTFE tube that offers exceptional resistance to aggressive chemicals and extreme temperatures. This core is then reinforced with a tough stainless steel braid. This construction provides exceptional strength, protecting the hose from high pressure and external damage while preventing kinking.

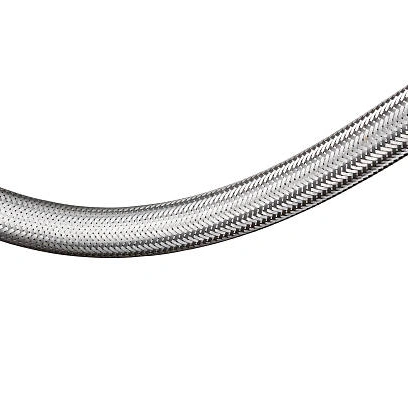

PTFE SS Braided Hose

PTFE SS Braided Hose consists of a PTFE liner and a stainless steel braid. The PTFE core is renowned for its inert properties, making it compatible with virtually any fluid, from harsh chemicals to high-purity substances. The “SS,” or stainless steel, braid provides critical support, enabling it to withstand high pressure, abrasion, and temperature fluctuations. This hose is a top choice for the automotive, pharmaceutical, and chemical industries, where reliability and long-term performance are crucial.

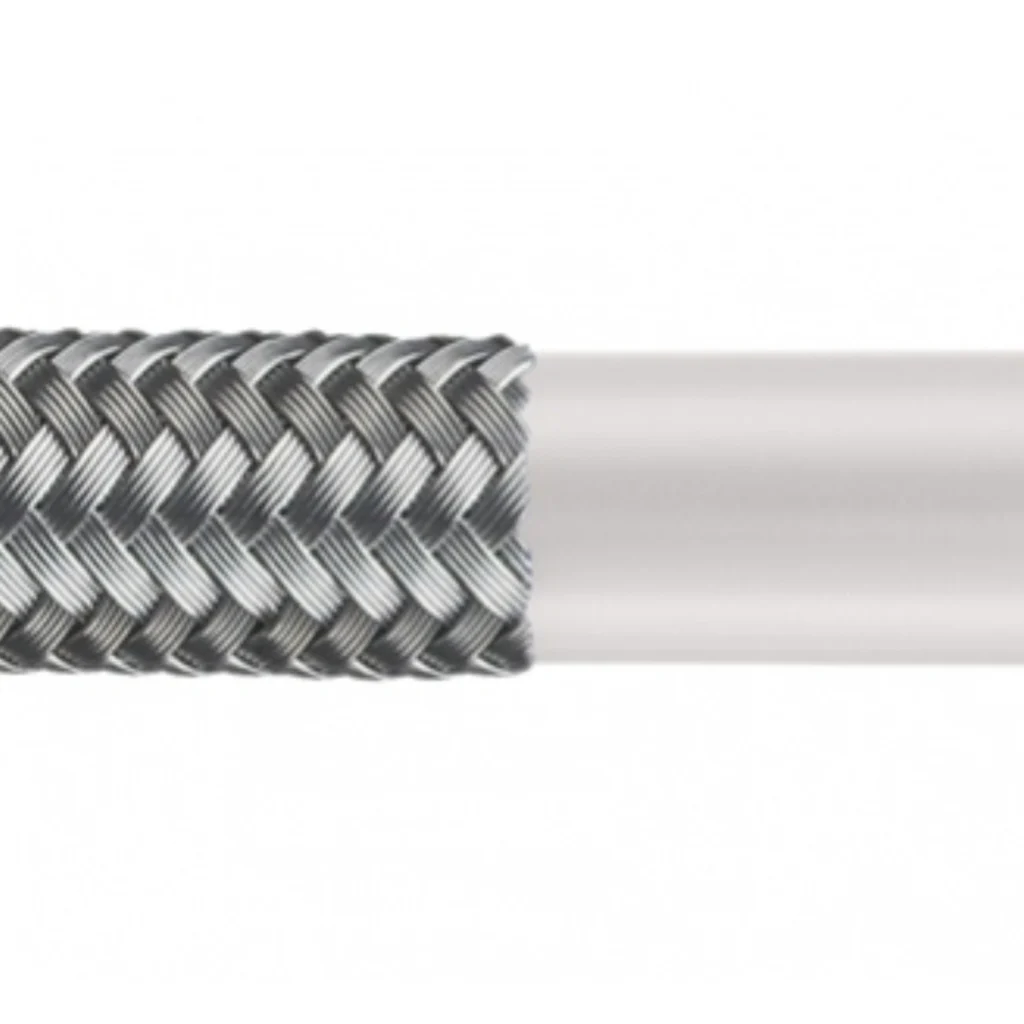

SS Braided Smooth Bore PTFE Hose

An SS braided smooth bore PTFE hose is engineered for high-purity and high-pressure applications. Its inner tube is made of smooth, non-stick PTFE, which is resistant to virtually all chemicals and high temperatures. The “SS” or stainless steel braid provides exceptional strength, preventing the hose from kinking or bursting. This design is ideal for industries like food and beverage, pharmaceuticals, and chemical manufacturing where sanitary, non-contaminating fluid transfer is a critical requirement.

PTFE Braided Fuel Hose

PTFE braided fuel hoses are ideal for modern fuel systems. The PTFE inner layer resists corrosion from ethanol, methanol, and other racing fuels, which can easily degrade traditional rubber hoses. The outer braid prevents kinking and abrasion, ensuring a secure, leak-free connection. Furthermore, these hoses effectively prevent fuel vapor permeation, which can lead to “fuel smell” in the vehicle cabin, making them an ideal upgrade for high-performance vehicles and racing applications.

PTFE Nylon Braided Hose

For a lightweight and flexible alternative to stainless steel, the PTFE nylon braided hose is an excellent option. The inner PTFE core provides the same unmatched chemical and temperature resistance. However, the outer braid is made from a durable nylon fiber. This design significantly reduces the hose’s weight while still providing good abrasion protection. It’s a popular choice in motorsport and other applications where weight savings are critical, offering a great balance of performance and flexibility.

PTFE Stainless Braided Fuel Oil Hose Line

PTFE stainless braided fuel oil hose line is a superior alternative to traditional rubber hoses for automotive and industrial fluid transfer. The PTFE inner core is chemically inert, making it completely resistant to the corrosive effects of modern fuels, oils, and other automotive fluids. The durable outer stainless steel braid prevents kinking and abrasion. This combination ensures a secure, leak-free connection, eliminates fuel vapor permeation, and provides a professional look for performance and racing applications.

Custom Ptfe Braided Hose Wholesale

Unmatched Chemical and Temperature Resistance

The core of a PTFE braided hose is its outstanding chemical and thermal properties. PTFE is a remarkably inert material that resists a wide range of corrosive acids, bases, and solvents. This makes the hose an excellent choice for transferring aggressive chemicals. Furthermore, it can operate reliably in a broad temperature range, from freezing conditions to extremely high heat, without losing its structural integrity.

Versatile Applications of R1 Hydraulic Hose

From aerospace to pharmaceutical manufacturing, a PTFE braided hose is a go-to solution for fluid transfer. Its non-stick inner surface ensures a pure flow and makes cleaning easy. The combination of its inertness, high-pressure rating, and temperature resistance makes it an invaluable component for hydraulic systems, fuel lines, steam transfer, and various food and beverage applications where purity is non-negotiable.

Structural Integrity and Durability

The signature feature of a PTFE braided hose is its robust construction. The outer stainless steel braid provides crucial protection, preventing the hose from collapsing under vacuum, kinking during bends, or bursting under high pressure. This reinforcement also shields the inner PTFE tube from external abrasions and cuts, ensuring a long and reliable service life, even in harsh industrial environments.

A Focus on Safety and Purity

Safety and purity are paramount when dealing with critical fluids. PTFE braided hoses excel in this regard due to their non-reactive PTFE inner core. This material won’t leach chemicals into the transferred fluid and is non-flammable. The secure, braided design minimizes the risk of leaks, providing a safer working environment and ensuring the integrity of the conveyed medium, a key concern in sensitive operations.

What is a PTFE braided hose?

A PTFE braided hose is a specialized hose with a polytetrafluoroethylene (PTFE) inner tube and a reinforcing outer braid, typically made of stainless steel. The PTFE core offers superior resistance to chemicals and temperature extremes, while the braiding provides the necessary strength to handle high pressure.

This construction makes the hose ideal for demanding applications. It ensures both a clean, pure flow of fluids and the durability to operate in harsh industrial, automotive, and aerospace environments.

What are the key advantages of using PTFE?

The primary advantages of using PTFE are its chemical inertness and its wide operating temperature range. PTFE is a highly stable material that does not react with most corrosive chemicals, acids, and solvents. This makes the hose exceptionally versatile.

Additionally, PTFE’s ability to perform reliably from sub-freezing temperatures to very high heat levels makes it suitable for a diverse set of applications. This thermal stability and chemical resistance make it a top choice for safety and long-term reliability.

Can these hoses handle both high temperature and high pressure?

Yes, PTFE braided hoses are specifically designed for both high temperature and high pressure. The PTFE core is inherently capable of withstanding extreme heat without degradation. The outer stainless steel braid provides the structural integrity to contain high internal pressures, preventing the hose from bulging or bursting.

This combination of thermal and pressure resistance makes them a superior choice compared to traditional rubber or plastic hoses. They are a go-to solution for critical applications like steam transfer and hydraulic systems.

What is the difference between smooth-bore and convoluted hoses?

The difference lies in the design of the inner PTFE tube. Smooth-bore PTFE braided hoses have a straight, flat inner surface, which allows for minimal flow restriction and is easier to clean, making them ideal for high-purity applications.

Convoluted PTFE braided hoses have a ribbed, corrugated inner surface. This design gives the hose extraordinary flexibility and a tight bend radius, making it perfect for applications with complex routing in tight spaces.

best way to cut ptfe braided hose

The best way to cut a PTFE braided hose is with a specialized hose cutting tool or a fine-tooth hacksaw. Before cutting, wrap the area with electrical tape to prevent the braid from fraying. A dedicated hose cutter, often with a razor-sharp blade, provides the cleanest, most precise cut. If using a hacksaw, a blade with 32 teeth per inch or more works best. Remember to secure the hose in a vise to ensure a straight, clean cut and to prevent the braid from unraveling.

Quote Ptfe Braided Hose Wholesale

Is your project held back by unsuitable hydraulic hoses? Don’t compromise on performance or struggle with ill-fitting components. We offer 3/16 hydraulic hose wholesale, custom-tailored to your exact specifications. Get precise lengths, ideal pressure ratings, and the perfect fittings for seamless integration, ensuring your systems operate with maximum efficiency and reliability, every time.