When choosing between nylon and stainless braided hoses, the decision hinges on performance, durability, and cost. At first glance, both materials seem similar—flexible, reinforced, and designed for fluid transfer. But dig deeper, and you’ll uncover critical differences that impact everything from installation to long-term reliability. In this guide, we’ll break down the key factors to help you decide which hose is best for your project.

What are Nylon Braided Hoses

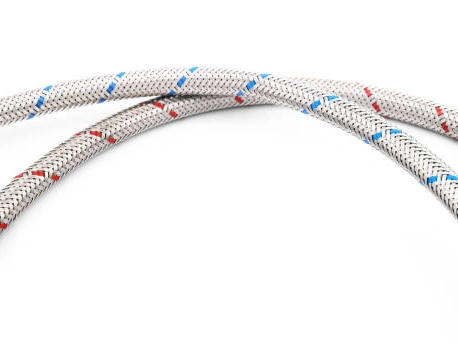

Nylon braided hose has become a highly popular option, and for good reason. These hoses typically feature an inner tube made from a synthetic rubber or advanced polymer like PTFE, which is then covered by a durable, lightweight nylon fiber braid. This construction offers a compelling balance of performance and practicality, making it a go-to for a wide range of applications.

- Weight Reduction: The primary advantage of nylon braid is its remarkably low weight. For projects where weight is a critical factor, such as in motorsports or aerospace, every gram counts. A complete fluid system with nylon hose can significantly reduce the overall mass of the vehicle or equipment.

- Aesthetic Customization: We offer nylon hoses in a variety of colors, allowing for a clean and customized aesthetic. This is a huge selling point for builders who want a visually cohesive and professional-looking engine bay or system layout.

- Flexibility and Installation: The lightweight and pliable nature of the nylon braid makes these hoses exceptionally flexible. This ease of bending and routing simplifies installation, especially in tight or complex spaces, saving valuable time and effort.

- Non-Marring Surface: Unlike its metallic counterpart, the smooth nylon exterior is less likely to scratch painted surfaces or other components during installation. This is a small detail that makes a big difference in the final quality of a build.

What are Stainless Braided Hoses

For decades, stainless braided hose has been the gold standard for high-stakes applications. These hoses feature a heavy-duty stainless steel wire braid woven tightly around a robust inner tube. This construction is engineered for maximum protection and durability, making it the preferred choice when failure is not an option.

- Extreme Durability: The stainless steel braid provides unmatched resistance to external physical threats. It can withstand severe abrasion, cuts, and impacts, making it ideal for environments where the hose might come into contact with sharp objects or road debris.

- Superior Pressure Handling: The sheer strength of the stainless steel braid reinforces the inner tube, allowing it to maintain integrity under extreme pressures. This is why it’s the standard for critical systems like brake lines, high-pressure fuel injectors, and power steering setups.

- Excellent Heat Resistance: Stainless steel itself is highly resistant to heat, and when combined with a quality inner liner, it provides exceptional thermal protection. This makes it the safe choice for lines running near high-temperature components like exhaust manifolds or turbochargers.

- Professional, Classic Look: The iconic metallic finish of a stainless steel braided hose provides a classic, professional, and industrial look that many builders prefer. It signifies a no-compromise approach to performance and reliability.

Nylon Braided vs. Stainless Braided

When advising our customers, we always present a clear comparison of the key performance metrics. This table summarizes the main differences to help you make an informed decision based on your priorities.

| Feature | Nylon Braided Hose | Stainless Braided Hose |

| Durability & Abrasion Resistance | Good; suitable for most applications. | Excellent; the industry standard for high-risk environments. |

| Weight | Lightweight; ideal for performance-focused builds. | Heavier; a consideration for weight-sensitive projects. |

| Flexibility | High; easy to route and install. | Low; more rigid and difficult to bend. |

| Pressure Rating | Very good; sufficient for many fluid systems. | Excellent; the best choice for high-pressure applications. |

| Aesthetic Options | Variety of colors for customization. | Classic, raw metallic look. |

| Cost | Typically more cost-effective. | Generally a higher price point. |

| Installation Risk | Low risk of marring surrounding components. | Higher risk of scratching surfaces if not handled carefully. |

Real-World Applications: Making the Right Choice

The ideal choice between nylon braided hose and stainless braided hose comes down to the specific system and its operating conditions. Here are a few examples based on my professional experience:

- Fuel Lines: For most standard fuel systems, a high-quality nylon braided hose is an excellent choice. It’s lightweight, flexible, and provides a clean, modern look. The weight savings and ease of installation are often major benefits here.

- Brake Lines: This is a non-negotiable application for stainless braided hose. The extreme pressure demands of a braking system require the unyielding strength of stainless steel to prevent hose expansion, which could lead to a spongy pedal feel or even catastrophic failure.

- Turbo Oil/Coolant Lines: These lines operate under both high temperature and moderate pressure. The superior heat resistance and durability of stainless braided hose make it a safer and more reliable option, protecting against potential failures in a critical area.

- Coolant & Vacuum Lines: For these lower-pressure, lower-heat applications, nylon braided hose is often a perfect fit. It offers a great balance of performance and cost-effectiveness, with the added benefit of aesthetic versatility.

How to Choose Braided Nylon Hose and Stainless Steel

When you’re ready to select a hose, consider these factors from a professional perspective.

- Choose the nylon braided hose if: Your project prioritizes weight savings, ease of installation, and a customized appearance, and the fluid system operates under moderate pressure and temperature conditions.

- Choose the stainless braided hose if: The application involves extreme pressure or heat, requires maximum durability against abrasion or physical damage, and reliability is the single most important factor.

Ultimately, both hose types are engineered for performance. Your choice should be a strategic decision based on the demands of your specific build.

Conclusion

As your supplier, we provide not only products but also the expertise to ensure your project is a success. If you have any questions or require personalized advice tailored to your specific application, we encourage you to contact our team.