Hydraulic hose pressure testing is a vital procedure for ensuring the safety and reliability of hydraulic systems. This process involves subjecting hydraulic hoses to controlled pressure levels to verify their integrity and performance under operational conditions. Understanding the nuances of pressure testing is crucial for industries relying on hydraulic equipment, from construction and mining to manufacturing and agriculture.

This comprehensive guide delves into the intricacies of hydraulic hose pressure testing, covering everything from the fundamental principles to advanced testing techniques.

We’ll explore the importance of adherence to industry standards, the diverse methods employed, and the critical role pressure testing plays in preventing catastrophic failures and ensuring efficient system operation.

What Is Hydraulic Hose Pressure Testing

Hydraulic hose pressure testing is a crucial procedure designed to evaluate the integrity and performance of hydraulic hoses under simulated operating pressures. This process involves subjecting the hoses to controlled pressure levels, often exceeding their rated working pressure, to identify any potential weaknesses, leaks, or failures. The testing ensures that the hoses can safely and reliably handle the pressures they will encounter in real-world applications.

The purpose of hydraulic hose pressure testing is to verify that the hoses meet industry standards and manufacturer specifications. This testing is essential for preventing catastrophic failures, which can lead to equipment damage, fluid leaks, and safety hazards. By rigorously testing hoses, manufacturers and users can ensure that hydraulic systems operate safely and efficiently.

Hydraulic Hose Pressure Testing Standards

Hydraulic hose pressure testing standards are crucial for ensuring the safety and reliability of hydraulic systems. These standards provide guidelines for conducting pressure tests, defining the parameters, procedures, and acceptance criteria.

Adherence to these standards guarantees that hydraulic hoses can withstand the pressures they’ll encounter in real-world applications, minimizing the risk of failures and leaks. Organizations like the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) publish these standards.

Here are some key aspects covered by hydraulic hose pressure testing standards:

- Proof Pressure Testing: Verifies the hose’s ability to withstand a pressure significantly higher than its working pressure without permanent deformation.

- Burst Pressure Testing: Determines the maximum pressure the hose can withstand before rupturing.

- Impulse Pressure Testing: Assesses the hose’s resistance to repeated pressure fluctuations, simulating cyclic loading.

- Leakage Testing: Checks for any leaks under pressure, ensuring the hose’s integrity.

- Temperature Testing: Evaluates the hose’s performance under extreme temperature conditions.

- Dimensional Stability: Checks for changes in hose dimensions after pressure testing.

- Materials and Construction Requirements: Specifies the quality and type of materials and construction methods for the hose.

Hydraulic Hose Pressure Test Procedure

Hydraulic hose pressure testing is essential for verifying the integrity and safety of hydraulic systems. Following a structured procedure ensures accurate results and minimizes the risk of failures. This guide outlines the steps on how to test hydraulic hose pressure:

Tools Needed for Hydraulic Hose Pressure Testing:

- Hydraulic pressure test bench

- Pressure gauges (calibrated)

- Adapters and fittings (compatible with hose and test bench)

- Hydraulic fluid (appropriate for hose and test conditions)

- Safety shields or enclosures

- Measuring tools (calipers, tape measure)

- Leak detection solution (soapy water or specialized fluid)

- Safety equipment (eye protection, gloves, etc.)

Step 1: Preparing the Hose and Test Setup

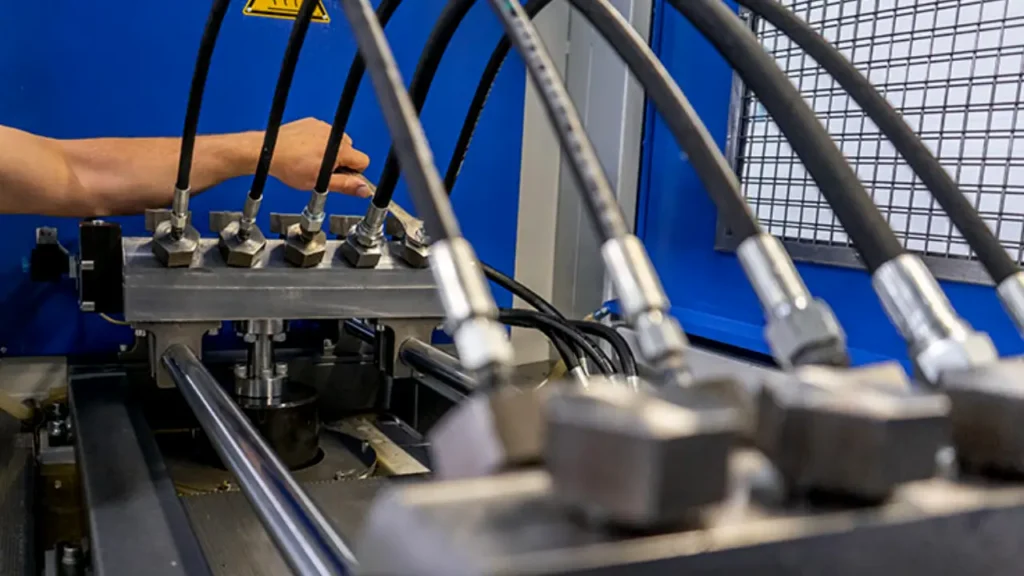

The initial step involves preparing the hydraulic hose for testing. This includes visually inspecting the hose for any damage, such as cuts, abrasions, or kinks. Ensure the hose is clean and free from debris. Connect the hose to the hydraulic pressure test bench using appropriate adapters and fittings. Verify all connections are secure to prevent leaks during testing.

Next, set up the hydraulic pressure test bench. This involves filling the system with the appropriate hydraulic fluid and calibrating the pressure gauges. Position safety shields or enclosures around the test area to contain any potential hose ruptures or fluid sprays. Ensure all safety equipment is in place and functioning correctly.

Accurate preparation is critical for obtaining reliable test results. Any flaw in the setup may cause an inaccurate reading or a dangerous failure.

Step 2: Conducting the Pressure Test

Once the hose and test setup are prepared, the pressure test can begin. Slowly increase the pressure in the hose to the specified test pressure, as defined by industry standards or manufacturer specifications. Hold the pressure for a predetermined duration, typically several minutes, to allow for thorough evaluation. Monitor the pressure gauges for any pressure drops, indicating leaks or hose expansion.

While the hose is under pressure, visually inspect it for any signs of leakage, bulging, or deformation. Use a leak detection solution, such as soapy water or a specialized fluid, to identify any leaks at the fittings or along the hose length. Record the pressure readings and any observations during the test.

Careful monitoring of the pressure is very important. Any sudden drop in pressure, or a change in the shape of the hose could mean a failure.

Step 3: Analyzing and Reporting Test Results

After completing the pressure test, carefully analyze the results. Compare the recorded pressure readings and observations to the acceptance criteria specified by industry standards or manufacturer specifications. Document any leaks, deformations, or failures observed during the test.

Prepare a comprehensive test report that includes details about the hose, test setup, procedure, and results. This report should include pressure readings, observations, and any deviations from the acceptance criteria. The test report is crucial for evaluating the hose’s performance and determining its suitability for its intended application.

Accurate reporting is crucial for proper record keeping, and to ensure that the hose tested, meets the standards required.

Hydraulic Hose Pressure Testing Equipment

Hydraulic hose pressure testing equipment ensures your hoses perform safely under high pressure conditions, preventing leaks and failures. Proper testing protects machinery, reduces downtime, and maintains workplace safety. Reliable equipment allows technicians to simulate real-world pressures and identify weak points before installation, extending hose life and improving overall system efficiency.

- Safety Assurance: Testing equipment verifies hose integrity under extreme pressures, preventing dangerous blowouts and system failures. Simulating operational conditions, it ensures hoses meet safety standards, protecting both operators and machinery. This step is critical in industries relying on high-pressure hydraulic systems.

- Performance Verification: Equipment measures a hose’s ability to withstand repeated pressure cycles without deforming or leaking. This helps detect manufacturing defects early and ensures consistent performance across all hoses, reducing maintenance costs and avoiding unexpected downtime.

- Efficiency Improvement: Regular testing identifies hoses that may underperform or fail prematurely. By addressing issues proactively, you maintain optimal hydraulic system efficiency, ensuring smooth operations, reducing energy losses, and extending the lifespan of connected components.

- Compliance with Standards: Advanced pressure testing devices help meet industry regulations and quality standards. They provide documented proof that hoses comply with pressure ratings, supporting audits, certifications, and customer confidence in your hydraulic products.

Hydraulic Hose Working Pressure and Burst Pressure

Hydraulic hose working pressure and burst pressure are two critical specifications that define a hose’s performance and safety limits.

Working Pressure:

This is the maximum pressure a hydraulic hose is designed to handle continuously during normal operation. It’s the pressure at which the hose can reliably function without failure or significant degradation over its intended lifespan. Operating a hose above its working pressure can lead to premature wear, leaks, or catastrophic ruptures.

Burst Pressure:

This is the maximum pressure a hydraulic hose can withstand before it bursts or fails catastrophically. It’s a significantly higher pressure than the working pressure, providing a safety margin. Importantly, as you mentioned, it is a common industry standard that the burst pressure is often designed to be at least four times the working pressure. This safety factor is essential to account for pressure spikes, surges, and other unexpected events in a hydraulic system.

Here’s why this distinction is important:

- Safety: The 4:1 safety factor helps prevent accidents and equipment damage.

- Reliability: Operating within the working pressure ensures a long and reliable hose lifespan.

- Performance: Choosing the right hose with appropriate working and burst pressures is critical for optimal system performance.

Therefore, when selecting a hydraulic hose, it’s essential to consider both the working pressure and the burst pressure, ensuring they meet the specific requirements of the application.

Hydraulic Hose Testing Standards

Hydraulic hoses are essential in fluid power systems, and testing ensures safety, reliability, and compliance with industry standards. Regular testing prevents leaks, bursts, and system failures while maintaining consistent performance. Knowing hydraulic hose testing standards helps engineers, manufacturers, and maintenance teams ensure optimal operation.

- SAE Standards – SAE (Society of Automotive Engineers) defines testing for hydraulic hoses, including pressure ratings, burst tests, and environmental resistance, ensuring hoses perform safely under high-pressure conditions while meeting rigorous industry expectations for durability, reliability, and consistent performance in demanding industrial applications.

- ISO Standards – ISO 1436 and related standards provide global testing benchmarks for hose dimensions, pressure, and performance. Adhering to ISO standards guarantees hoses can be used internationally, delivering consistent operational safety, high reliability, and long-term durability across various hydraulic systems and industrial environments.

- Pressure Testing – Pressure tests, including proof and burst tests, evaluate a hose’s ability to handle maximum operating pressures without failure. This ensures system reliability, prevents leaks or ruptures, and helps avoid costly downtime, protecting equipment and personnel in critical hydraulic applications.

- Environmental and Flexibility Tests – Hoses undergo testing for temperature extremes, chemical exposure, abrasion, and repeated bending cycles. These tests ensure hoses maintain integrity under harsh conditions, extending their service life, ensuring reliable performance, and maintaining safety in demanding industrial and mobile hydraulic systems.

- Certification and Documentation – Manufacturers provide certified test reports documenting compliance with all relevant standards, including performance results. This documentation is essential for quality assurance, regulatory adherence, and customer confidence, proving that hydraulic hoses meet required specifications for safe and reliable operation.

Conclusion

Hydraulic hose pressure testing is an indispensable process for verifying the safety and reliability of hydraulic systems. By subjecting hoses to pressures exceeding their rated capacity, potential weaknesses and defects are identified, preventing catastrophic failures. Understanding the various testing methods and industry standards ensures informed decisions, safeguarding both equipment and personnel.

Adhering to rigorous testing protocols guarantees that hydraulic systems operate efficiently and safely. Regular pressure testing extends hose lifespan, minimizes downtime, and ultimately reduces operational costs. Prioritizing quality and compliance in hose selection and maintenance is crucial for maintaining system integrity.

For dependable, hydraulic hoses that meet stringent pressure testing standards, choose Gushan Rubber. We offer a wide range of wholesale options designed to enhance your hydraulic system’s performance and safety. Contact us today to discuss your specific needs and receive a tailored quote.