It’s easy to focus on the big, moving parts—the pumps, cylinders, and valves—but in my experience, the true magic lies in the invisible force that drives them: hydraulic fluid. This specialized liquid is more than just oil; it’s the lifeblood of your system, and its health is directly tied to the performance and longevity of your hydraulic hoses. We want to take you on a deep dive into the world of hydraulic fluid.

What is Hydraulic Fluid?

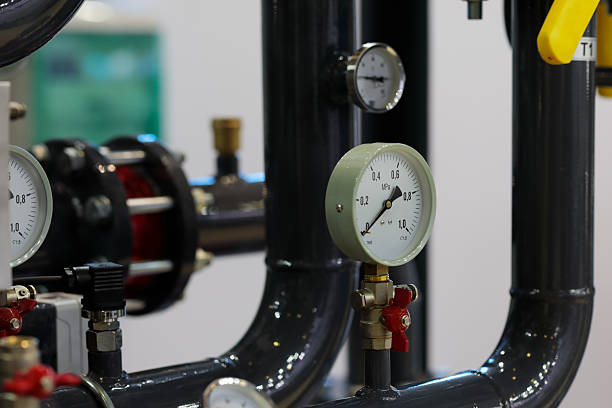

When you see a forklift lifting a heavy pallet or an excavator digging into the earth, you’re witnessing the power of fluid dynamics at work. At its core, hydraulic fluid is a non-compressible liquid used to transmit power within a hydraulic system. It transforms mechanical energy into fluid energy, which is then directed to perform work. But its job doesn’t stop there.

This versatile fluid also acts as a lubricant for moving parts, dissipates heat generated during operation, and seals gaps between components. It’s the single most important element in ensuring your system runs smoothly and efficiently.

What is Hydraulic Fluid Made Of?

While the term “hydraulic oil” is often used interchangeably, the truth is that modern hydraulic fluid is a sophisticated blend, not a simple oil. Its properties are carefully engineered to meet the demanding conditions of hydraulic systems, which often involve high pressures and extreme temperatures. The composition is what gives the fluid its specific characteristics, allowing it to perform multiple functions simultaneously. Understanding these components is key to appreciating what makes a high-quality fluid so effective.

The Two Core Components of Hydraulic Fluid:

- Base Oil: This is the primary constituent, forming the bulk of the fluid. It determines the fluid’s fundamental properties like viscosity, thermal stability, and flash point. Common base oil types include mineral oil (the most common), synthetic oil, and water-based fluids.

- Additives: These are the performance enhancers. They are mixed into the base oil to boost specific properties and protect the system components. Without these additives, the fluid would break down quickly and fail to protect your expensive machinery.

| Additive Type | Primary Function | Benefit to the System |

| Anti-Wear Agents | Creates a protective film on metal surfaces | Reduces friction and component wear in high-pressure applications |

| Antioxidants | Slows down the fluid’s oxidation process | Extends fluid life, prevents sludge and acidic buildup |

| Rust & Corrosion Inhibitors | Forms a protective barrier on metal surfaces | Prevents rust and corrosion, especially in wet environments |

| Viscosity Index Improvers | Stabilizes viscosity across a wide temperature range | Ensures consistent performance in both hot and cold conditions |

| Anti-Foaming Agents | Allows trapped air bubbles to quickly dissipate | Prevents cavitation, spongy operation, and fluid damage |

What Type of Hydraulic Fluid for Hydraulic Hoses?

Choosing the correct hydraulic fluid for your system is paramount, and a major part of that decision hinges on the type of hydraulic hoses you’re using.

An incompatible fluid can lead to catastrophic hose failure—a swollen inner tube, a delaminated lining, or a complete rupture. It’s a classic case of knowing your components to ensure they work together harmoniously. Here are the most common types of hydraulic fluids and their corresponding hose compatibility.

- Mineral-Based Hydraulic Fluid: This is the most widely used and cost-effective fluid, derived from crude oil. It’s ideal for a vast range of industrial and mobile equipment. Hoses with Nitrile (NBR) rubber or certain synthetic rubber inner tubes are typically compatible with this type of fluid.

- Synthetic Hydraulic Fluid: Known for its superior performance, synthetic fluid offers a wider operating temperature range and a longer service life than mineral oil. It’s often used in high-performance or extreme-temperature applications. These fluids require hoses with specialized linings, such as fluorocarbon (Viton) or specific synthetic rubbers designed for chemical resistance.

- Water-Based Hydraulic Fluid: The key advantage of this fluid is its fire-resistant property, making it a critical choice for environments with a high risk of fire, such as steel mills or foundries. Due to the high water content, it requires hoses with inner tubes made of materials like Butyl rubber or EPDM rubber, which can withstand the fluid’s unique chemical makeup.

How to Check Hydraulic Fluid?

Regular fluid checks are one of the easiest and most effective preventative maintenance tasks you can perform. It can alert you to potential issues before they cause costly damage. Don’t wait until your equipment starts acting up—make fluid checks a routine part of your maintenance schedule.

Here’s a quick guide to checking your hydraulic fluid:

- Visual Inspection: Start by looking at the fluid in the reservoir. Healthy hydraulic fluid should be clear and have a consistent amber color. If you see a milky, cloudy appearance, it likely indicates water contamination. If the fluid is dark and opaque, it’s probably oxidized and needs to be changed.

- Smell Test: This might sound basic, but it can be surprisingly revealing. A healthy fluid should have a faint, petroleum-like smell. If you detect a burnt or sour odor, it’s a strong indicator of overheating or chemical breakdown.

- Level Check: Always ensure the fluid level is within the designated range on the reservoir’s sight glass or dipstick. An overfilled reservoir can cause foaming and pressurization issues, while a low fluid level can lead to cavitation and pump damage.

- Oil Analysis (for Critical Systems): For mission-critical equipment, a professional oil analysis is invaluable. A lab can test for wear particles, contamination, and additive levels, giving you a comprehensive health report of your hydraulic fluid.

The Crucial Relationship Between Hydraulic Fluid and Hydraulic Hoses

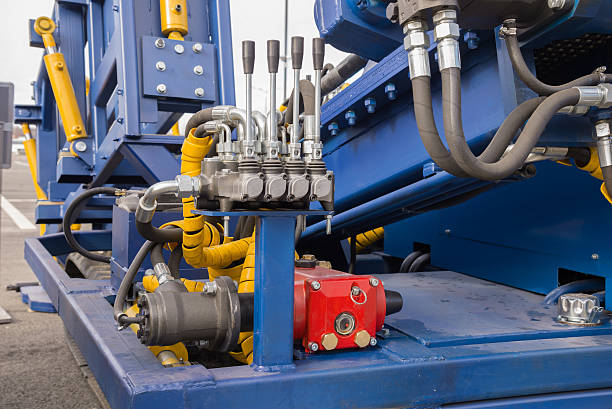

The connection between hydraulic fluid and hydraulic hoses is more than just a passing acquaintance—it’s a critical, symbiotic relationship. The hose’s inner tube, designed to contain the fluid, must withstand not only high pressures but also the fluid’s chemical composition. When this relationship breaks down, the results can be catastrophic.

- How Fluid Affects the Hose: A fluid that’s chemically incompatible with the hose’s inner tube can cause it to swell, harden, or become brittle over time. This reduces the hose’s flexibility and strength, making it vulnerable to bursts. Furthermore, degraded fluid with acidic properties can slowly erode the inner wall, leading to microscopic tears and eventual failure.

- How the Hose Affects the Fluid: An aging or damaged hose can contribute to fluid contamination. As the inner tube material breaks down, tiny rubber particles can flake off and enter the fluid stream. These contaminants can clog filters, wear down seals, and accelerate the wear of precision-fit components like valves and pumps.

How to Know if Hydraulic Fluid is Compatible for Hydraulic Hoses?

Ensuring compatibility between hydraulic fluid and hydraulic hoses is not a matter of guesswork; it’s a matter of due diligence. Failing to do so can result in system inefficiency, premature hose failure, and unnecessary downtime. I always follow a simple, three-step process to guarantee I’m making the right choice.

- Consult the Manufacturer’s Specifications: This is your most reliable source of information. Both the fluid and hose manufacturers provide detailed data sheets that list compatible materials. Before you buy, check the hose’s inner tube material and cross-reference it with the fluid’s compatibility table.

- Match the Hose Material to the Fluid Type: As a general rule of thumb, you need to match the hose’s inner tube material to the fluid type. For example, most standard Nitrile hoses are designed for petroleum-based fluids, while Fluorocarbon (Viton) is a go-to for many synthetic fluids. When in doubt, always default to a hose with a lining designed for universal or broad chemical resistance.

- Seek Expert Advice: If you’re working with a specialized system or an unusual fluid, don’t hesitate to reach out to a hydraulics expert. Your fluid distributor or hose manufacturer’s technical support team can provide invaluable guidance and ensure you’re not taking any risks.

Conclusion

Hydraulic fluid is the core of any hydraulic system, serving as the medium for power, lubrication, and cooling. Its crucial relationship with hydraulic hoses dictates the overall health and safety of your machinery.

By understanding what it is, what it’s made of, and how to check for its health, you empower yourself to make smarter maintenance decisions.