Hydraulic systems are the workhorses of many industries, from construction and agriculture to manufacturing and transportation. They provide the immense power needed to lift, push, and move heavy loads. This power comes with a significant risk: the potential for a hydraulic hose to fail.

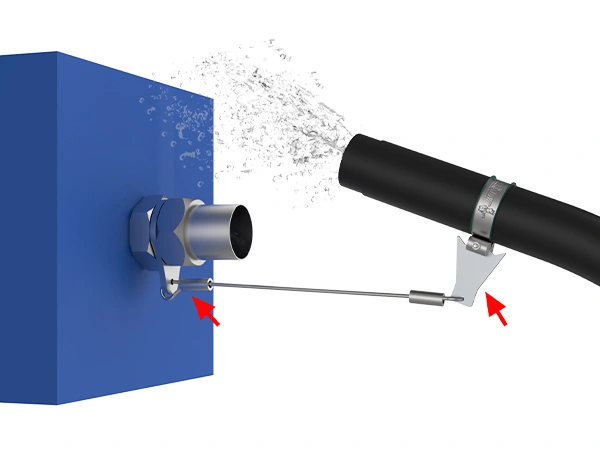

When a hose ruptures under high pressure, it can whip violently, posing a danger to anyone in the vicinity. This is where hydraulic hose safety restraints come in, and understanding them is crucial for maintaining a safe working environment.

What Are Hydraulic Hose Safety Restraints?

When I first started working with heavy machinery, we were always a bit wary of the hydraulic lines. We knew the pressure they contained and the force they exerted. That’s when I learned about hydraulic hose safety restraints.

In simple terms, these restraints are devices designed to contain a hydraulic hose in the event of a failure, preventing the dangerous “hose whip” that can occur when a hose bursts. They’re a simple yet incredibly effective safety measure that can mean the difference between a close call and a serious injury.

They typically consist of a strong sleeve or a series of cables that are attached to the hose and then anchored to a secure point on the machinery. Think of them as a leash for your hydraulic hoses. The most common types include:

- Nylon Sleeves: These are durable, woven sleeves that slide over the hose. They’re great for containing spray and small leaks, and some are even rated to restrain a full hose burst.

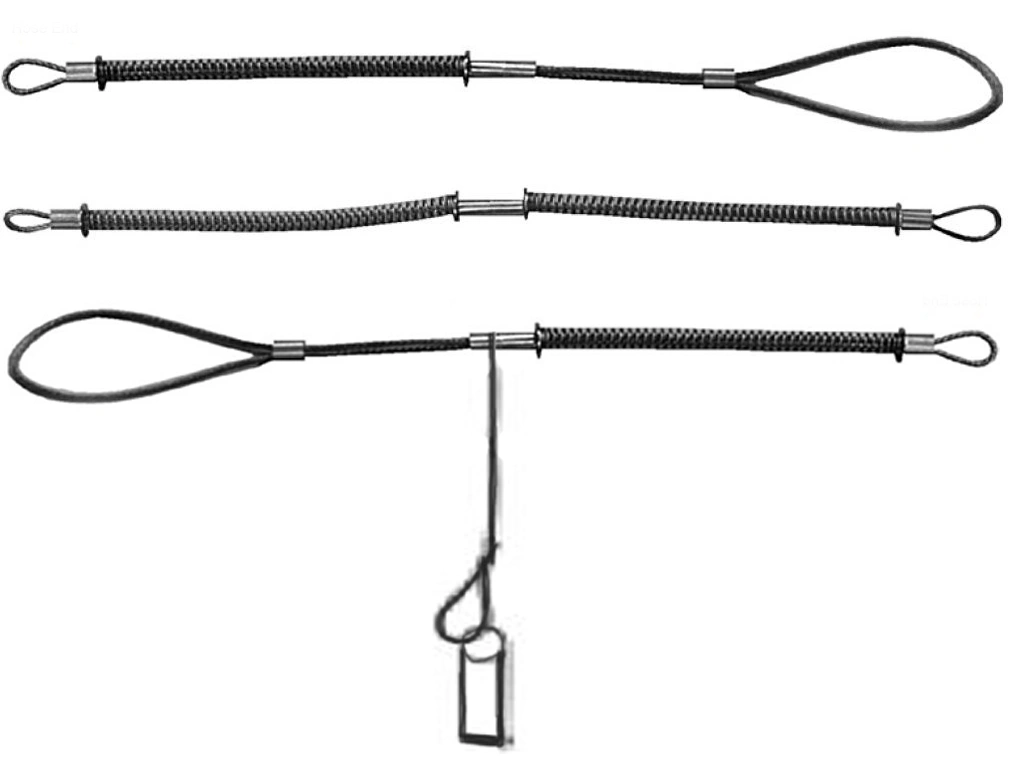

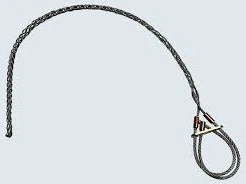

- Whip Socks: These are braided metal or high-strength textile socks that are installed over the hose and crimped at the ends. They’re specifically designed to absorb the force of a hose rupture and prevent whipping.

- Cables or Lanyards: Often used in conjunction with other restraints, these are simple but effective cables that attach the hose to the machine’s frame, limiting its movement in the event of a failure.

Why Do We Use Hydraulic Hose Safety Restraints?

The question isn’t so much “why” but “why wouldn’t you?” I’ve seen firsthand the destructive power of a whipping hydraulic hose. It’s not just a minor inconvenience; it’s a genuine hazard that can cause severe injuries or even death. The primary purpose of these restraints is to protect personnel and equipment from this kind of catastrophic failure.

High-pressure hydraulic hoses store immense energy. A sudden rupture can release this energy in a split second, causing the hose to flail uncontrollably with incredible force. Here’s a quick breakdown of why they are so vital:

- Personnel Safety: This is the most important reason. A whipping hose can strike a worker, causing blunt force trauma, lacerations, or even death. Hydraulic hose safety restraints contain this danger, ensuring that if a hose fails, it doesn’t become a lethal weapon.

- Equipment Protection: The force of a whipping hose can also damage surrounding equipment, wiring, and other hoses. By containing the failed hose, you minimize the risk of a domino effect of failures and costly repairs.

- Environmental Protection: A hose rupture can spray hydraulic fluid over a wide area. This fluid can be hot and can cause burns, but it also poses an environmental hazard. The sleeve-type restraints can help contain the fluid, making cleanup easier and reducing the environmental impact.

How to Install Hydraulic Hose Safety Restraints

Proper installation is key to ensuring that hydraulic hose safety restraints do their job effectively. It’s not a complicated process, but it requires attention to detail. I always follow the manufacturer’s instructions to the letter, as each type of restraint can have specific requirements. However, there are some universal best practices that I always adhere to.

A Step-by-Step Installation Guide

- Inspect the Hose: Before you even think about installing a restraint, make sure the hose itself is in good condition. Check for cracks, abrasions, or any signs of wear. A faulty hose should be replaced, not just restrained.

- Choose the Right Restraint: The type of restraint you choose should match the size and pressure rating of the hose. A small whip sock won’t be effective on a large, high-pressure hose. Consult the manufacturer’s charts to ensure a proper fit.

- Position the Restraint: For whip socks or cable restraints, they should be attached as close as possible to the connection points (fittings). This is where the highest concentration of pressure and stress occurs, and it’s the most common failure point.

- Secure the Restraint: Use the provided fasteners, clamps, or crimps to secure the restraint firmly to the hose. Make sure there’s no slack. The restraint should be snug but not so tight that it pinches the hose.

- Anchor the Restraint: This is a critical step. The restraint must be anchored to a strong, stationary part of the machine’s frame. A weak anchor point will fail just as easily as the hose itself. Use a secure bolt or clamp to attach the restraint to the anchor point.

When to Use Hydraulic Hose Safety Restraints

Determining when to use these restraints isn’t a complex puzzle. In my experience, if a hydraulic hose is under high pressure and poses a risk to people or equipment, it requires a safety restraint. The rule of thumb we use is simple: if the hose operates at pressures above 1000 psi (69 bar), a restraint is a non-negotiable safety measure. However, there are other factors to consider.

| Condition | Recommendation |

| High-Pressure Applications | Always use a restraint on hoses operating at pressures over 1000 psi (e.g., excavators, cranes, hydraulic presses). |

| Close Proximity to Personnel | If the hose is near a machine operator, maintenance worker, or anyone else, a restraint is essential to protect them from a potential failure. |

| Hoses in High-Traffic Areas | If the hose runs through an area where other equipment or people move, a restraint prevents a failure from causing wider damage or injury. |

| Hoses with a History of Failures | If a specific type of hose or application has a known history of failures, restraints should be mandatory. |

| High-Vibration or High-Movement Applications | Hoses on moving parts or in high-vibration environments are more prone to fatigue failure. Restraints offer an extra layer of protection. |

| Environmental or Property Damage Concerns | If a hose failure would cause significant environmental contamination or damage to expensive equipment, a restraint is a wise investment. |

Conclusion

Hydraulic hose safety restraints are a perfect example of this shift. They’re not a luxury; they’re a necessity for anyone operating high-pressure hydraulic equipment. By understanding what they are, why we use them, and how to install them correctly, we can create a safer and more reliable working environment.

Making safety a priority isn’t just about following regulations; it’s about protecting ourselves, our colleagues, and our investments. Next time you’re inspecting your equipment, take a moment to check if your hydraulic hoses are properly restrained. Your safety might just depend on it.