From sprawling construction sites to bustling factory floors, and across vast agricultural lands, hydraulic cylinders are ubiquitous, silently transforming fluid power into the powerful linear motion that underpins our progress and development. They are the “muscles” of many machines, but it’s the network of high-pressure hoses and fittings that truly enables them, empowering these machines to lift, push, pull, and precisely control heavy loads.

In this comprehensive article, we will delve into the extensive applications of hydraulic cylinders, revealing how they drive the world around us.

What is a Hydraulic Cylinder

When we talk about the powerhouse components of modern machinery, the hydraulic cylinder inevitably comes to mind. Essentially, it’s a mechanical actuator that converts the energy of pressurized hydraulic fluid into linear mechanical force and motion. We often describe it as the “muscle” of a hydraulic system.

Its operation is elegantly simple: high-pressure fluid, typically oil, is directed into the cylinder, pushing a piston along its bore. This piston is connected to a rod, which then extends or retracts, delivering a powerful pushing or pulling force to an external load. This fundamental capability allows hydraulic cylinders to perform tasks requiring immense force with remarkable precision.

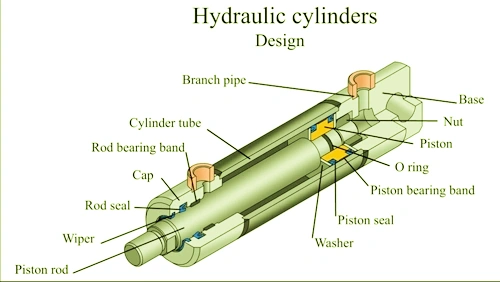

Main Components of Hydraulic Cylinder

When we look inside a hydraulic cylinder, we discover several critical parts working in perfect harmony to achieve its powerful function. Each component plays a vital and distinct role in ensuring efficient, reliable, and safe operation. Understanding these parts helps us appreciate the intricate engineering and precision involved in their design and manufacture.

At its core, we have the Cylinder Barrel, a precision-honed tube that forms the main body and contains the pressurized fluid and piston. Inside, the Piston is a disc-shaped component that fits snugly, dividing the barrel into two distinct chambers. Attached to the piston is the Piston Rod, a hardened and polished steel shaft that extends out of one end, transmitting the linear force to the external load.

End Caps, also known as heads or caps, securely close off both ends of the cylinder barrel. One end cap features a bore through which the piston rod passes, while the other seals the opposite end. Crucial for maintaining pressure and preventing fluid leakage are the various Seals—found around the piston, piston rod, and sometimes the end caps—made from durable materials like rubber or PTFE.

Ports are threaded openings in the cylinder body, serving as the entry and exit points for the hydraulic fluid, connecting the cylinder to the hydraulic pump and control valves. These components collectively enable the cylinder to convert hydraulic power into controlled linear motion.

How Does a Hydraulic Cylinder Work?

We often marvel at the seemingly effortless power exerted by heavy machinery. At the heart of this capability lies the hydraulic cylinder, a brilliant piece of engineering that transforms the quiet force of fluid pressure into robust linear motion. It’s a testament to the principles of fluid dynamics, specifically Pascal’s Principle, which dictates that pressure applied to an enclosed fluid transmits equally in all directions. This allows a relatively small input of pressure from a pump to generate an immense output force at the cylinder.

Imagine a sealed tube, the cylinder barrel, with a precisely fitted disc, the piston, dividing it into two chambers. When we introduce high-pressure hydraulic fluid, typically a specialized oil, into one of these chambers (say, the “cap end”), this incompressible fluid has nowhere to go but to exert force directly onto the face of the piston. Because the fluid cannot be compressed, it relentlessly pushes the piston.

As the piston is forced to move, it drives an attached piston rod linearly out of the cylinder. To retract the rod, we simply reverse the flow, directing the pressurized fluid into the opposite chamber (the “rod end”), which then pushes the piston back to its original position. This continuous cycle of fluid ingress and egress allows for precise control over the cylinder’s extension and retraction, converting the hydraulic energy into tangible mechanical work.

What is a Hydraulic Cylinder Used For

The sheer ubiquity of hydraulic cylinders is truly remarkable, and as those involved in the supply chain for hydraulic components, we see them at work almost everywhere in modern industrial and mobile equipment. Their unparalleled versatility allows them to power an incredibly diverse range of machinery across numerous sectors. It’s a profound testament to their fundamental utility in efficiently converting fluid power into precise and powerful mechanical work, enabling operations that would otherwise be impossible.

Here are just a few detailed examples of industries and applications where hydraulic cylinders are absolutely indispensable:

Construction and Earthmoving: Building the Future

In the construction industry, hydraulic cylinders are the very foundation of heavy machinery. We see them in:

- Excavators, Backhoes, and Loaders: Every articulation of the boom, stick, and bucket for digging, lifting, and dumping is powered by multiple hydraulic cylinders. Our high-pressure hoses ensure fluid reaches these cylinders even as the machine twists and turns.

- Cranes (Mobile and Tower): Cylinders extend and retract telescopic booms, raise and lower hooks, and deploy stabilizing outriggers, enabling safe and precise lifting of massive loads.

- Dump Trucks: Large telescopic cylinders effortlessly lift and tilt the truck beds for rapid material discharge.

- Concrete Pumps and Piling Rigs: Cylinders deploy support legs and articulate booms, or drive piles into the ground, ensuring stability and power for critical tasks.

Manufacturing and Industrial Processes: Precision and Force

In factories, hydraulic cylinders provide the brute force and fine control needed for mass production:

- Presses (Stamping, Forming, Forging): They apply immense, controlled force to shape metals, plastics, and other materials.

- Injection Molding Machines: Cylinders control mold clamping, opening, and the injection unit’s movement, crucial for producing complex plastic parts with high precision.

- Clamping Systems: Providing robust and consistent clamping force for workpieces during machining or assembly, ensuring accuracy and safety.

Agriculture: Cultivating Efficiency

Modern agriculture heavily relies on hydraulic power to boost productivity:

- Tractors and Implements: Cylinders control the three-point hitch for raising/lowering plows and planters, operate front-end loaders, and adjust various towed implements for precise farming. Our hoses are designed to withstand the harsh outdoor conditions.

- Combine Harvesters: They manage the header height, grain auger deployment, and other critical functions for efficient crop harvesting.

- Balers and Sprayers: Cylinders compress material in balers or extend wide booms for uniform spraying.

Material Handling and Logistics: Moving the World’s Goods

In warehouses, ports, and distribution centers, hydraulic cylinders are key to efficient movement:

- Forklifts and Scissor Lifts: Lifting and tilting loads, or elevating platforms for high-reach access.

- Container Handlers: Massive cylinders grip, lift, and stack multi-ton shipping containers in ports.

- Pallet Jacks and Conveyor Systems: Providing lifting for pallets or adjusting conveyor heights.

Marine and Offshore: Conquering Water Environments

The marine sector demands robust solutions for harsh conditions:

- Steering Gears: Large vessels use hydraulic cylinders to drive their rudders for precise navigation.

- Deck Cranes and Hatch Covers: Lifting cargo, launching lifeboats, or opening/closing massive cargo hold covers. Our marine-grade hoses resist saltwater corrosion.

- Offshore Drilling Platforms: Cylinders control drilling equipment, blowout preventers, and other heavy machinery in demanding environments.

Beyond these, hydraulic cylinders are also crucial in Automotive (car lifts, heavy vehicle braking), Aerospace (landing gear, flight control surfaces), Mining (drilling rigs, haul trucks), and Energy (wind turbine pitch control, dam gate operation). Their ability to deliver high force, precise control, and robust performance makes them truly indispensable across the industrial landscape.

How Do I Tell if My Hydraulic Cylinder is Bad?

Recognizing the early signs of a malfunctioning cylinder is crucial for preventing costly downtime and more severe damage. Here are some common indicators that can help us determine if a hydraulic cylinder is going bad:

1. External Fluid Leaks

This is usually the most obvious sign. If we notice hydraulic fluid pooling underneath the equipment or noticeable oil marks around the cylinder, piston rod, or joints, it usually indicates that the seals (for example, rod seals, piston seals, or O-rings) are worn, aged, or damaged. Leaks not only lead to oil loss and reduced system efficiency, but also introduce contaminants that accelerate internal wear.

2. Slow or Erratic Movement

A hydraulic cylinder should provide smooth, consistent motion. If we observe the equipment moving sluggishly, hesitating, or exhibiting “jerky” or “juddering” movements, it’s a clear signal of an internal issue. Common causes include internal leakage across the piston seal, air mixed into the hydraulic fluid (aeration or cavitation), increased friction due to fluid contamination, or even a bent piston rod.

3. Unusual Noises

Hydraulic systems are generally designed to operate quietly. If we start hearing knocking, banging, hissing, or excessive vibrations from the cylinder, these are warning signs. Such noises can stem from air bubbles collapsing within the fluid (cavitation), metal-on-metal friction from worn components, a bent rod rubbing against the cylinder wall, or loose mounting points.

4. Overheating

While cylinders generate some heat during operation, an abnormally high surface temperature on the cylinder barrel indicates a problem. Overheating is often a symptom of inefficiency, potentially caused by internal or external leakage forcing the pump to work harder, excessive friction (e.g., worn seals), contaminated or low fluid levels, or inadequate system cooling.

5. Failure to Hold Load (Drift)

If a hydraulic cylinder fails to maintain its position under load, slowly retracting or extending when it should be stationary, this is known as “drift.” This is a strong indicator of internal leakage past the piston seal, meaning pressure cannot be effectively maintained within the cylinder’s chambers.

If any of these signs are observed, we recommend prompt professional inspection and diagnosis to prevent escalation of the problem and ensure safe and efficient equipment operation.

Conclusion

In concluding our exploration of what a hydraulic cylinder is used for, it becomes abundantly clear that these powerful components are far more than mere mechanical parts; they are the very heart of countless machines that shape our modern world.

As suppliers of the critical hoses that enable these systems, we witness daily how these robust actuators, seamlessly connected by high-quality fluid pathways, drive progress across virtually every industry. Their continuous evolution promises an even more pivotal role in the innovations of tomorrow.