Among the many components that make this possible, the hydraulic cylinder stands out as a true workhorse. If you’ve ever seen heavy machinery in action-whether it’s an excavator shoveling dirt, a forklift lifting a heavy pallet, or a dump truck raising its bed-you’ve witnessed the power of hydraulic cylinders.

In this comprehensive guide, we’ll delve into the fascinating world of these essential devices, exploring what they are, how they work, and why they’re so crucial to countless industries.

What is a Hydraulic Cylinder

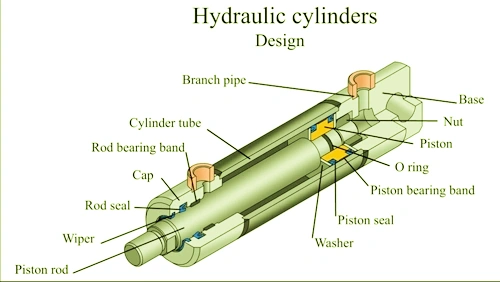

We often get asked about the basics, and it’s a great place to start. At its core, a hydraulic cylinder, also sometimes referred to as a hydraulic ram or linear hydraulic motor, is a mechanical actuator that converts hydraulic energy into linear mechanical force and motion.

It’s essentially a simple yet incredibly powerful device that uses pressurized hydraulic fluid to create a pushing or pulling force. This force is then used to move, lift, or press heavy loads with remarkable efficiency and control.

How Does a Hydraulic Cylinder Work?

Understanding the mechanism behind these powerful components is key to appreciating their versatility. We’ve always found it helpful to visualize the process. The operation of a hydraulic cylinder is based on Pascal’s Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. In a hydraulic cylinder, this principle is put to work to generate substantial force from a relatively small input of pressure.

- Fluid Input: High-pressure hydraulic fluid, typically oil, is pumped into one end of the cylinder by a hydraulic pump.

- Pressure Application: This fluid exerts pressure on the face of the piston, which is housed inside the cylinder barrel.

- Piston Movement: Because the fluid is incompressible, the pressure forces the piston to move linearly along the bore of the cylinder.

- Rod Extension/Retraction: The piston is connected to a piston rod, which extends out of one end of the cylinder, converting the hydraulic pressure into mechanical work. To retract the rod, fluid is typically directed to the opposite side of the piston, pushing it back.

Types of Hydraulic Cylinders

When we talk about hydraulic cylinders, it’s important to recognize that they aren’t a one-size-fits-all component. Different applications demand specific designs to optimize performance and efficiency. While the core principle of converting hydraulic pressure into linear force remains the same, the way this force is applied and controlled leads to several distinct types. Understanding these variations helps us appreciate their versatility across various industries.

Single-Acting Hydraulic Cylinders

We often encounter single-acting cylinders in simpler lifting or pressing applications. These cylinders are designed to receive hydraulic fluid on only one side of the piston. When pressurized fluid enters, it extends the piston rod. For the return stroke, the fluid pressure is released, and the piston retracts due to an external force, such as the weight of the load, a built-in spring, or gravity. This design makes them cost-effective for tasks where controlled retraction isn’t critical.

Double-Acting Hydraulic Cylinders

These are arguably the most common and versatile type we work with. Unlike single-acting cylinders, double-acting cylinders allow hydraulic fluid to be supplied to both sides of the piston. This means we can actively control both the extension and retraction of the piston rod. By directing fluid to the “cap end,” the rod extends; by directing it to the “rod end,” it retracts. This precise two-way control makes them indispensable for machinery requiring controlled movement in both directions, like excavators and forklifts.

Telescopic Hydraulic Cylinders

When we need a very long stroke from a compact retracted length, we turn to telescopic cylinders. These cylinders are characterized by multiple stages or sleeves, similar to a telescope, that extend one after another. This unique design allows them to achieve significantly longer extensions than conventional single or double-acting cylinders of the same retracted length. They are particularly useful in applications such as dump trucks, where the bed needs to be raised high, or cranes requiring extended reach.

Plunger Cylinders

Plunger cylinders represent a more specialized type, often used for high-force, short-stroke applications. In this design, the piston rod itself acts as the piston, meaning it has the same diameter as the cylinder bore. This eliminates the need for a separate piston head and seals on the piston, simplifying the construction. They are typically single-acting and are known for their robustness and ability to handle very heavy loads, making them suitable for certain types of presses or jacks.

Advantages of Using Hydraulic Cylinders

We’ve consistently observed the numerous benefits that hydraulic cylinders bring to various industries. Their widespread adoption isn’t by chance; it’s due to their inherent advantages in power transmission and control. These benefits make them indispensable for a vast array of heavy-duty applications.

Some of the key advantages include:

- High Force Output: They can generate immense forces, making them suitable for lifting, pushing, and pressing extremely heavy loads that other actuators cannot handle.

- Precision Control: With the right control valves, hydraulic cylinders offer precise control over speed, direction, and position. This is critical for delicate operations as well as heavy-duty tasks.

- Durability and Robustness: Built from strong materials and designed to withstand high pressures and harsh environments, they are incredibly durable and have a long operational lifespan with proper maintenance.

- Efficiency: They are highly efficient in converting hydraulic power into linear motion, with minimal energy loss when properly designed and maintained.

- Compact Design (Power Density): Despite their immense power, hydraulic cylinders are relatively compact, offering high power density – a significant amount of force from a small package.

- Smooth Operation: The use of incompressible fluid results in smooth and consistent motion, minimizing shock and vibration.

What is a Hydraulic Cylinder Used For

The ubiquity of hydraulic cylinders is truly remarkable, and we see them at work almost everywhere in modern industrial and mobile equipment. Their versatility allows them to power a diverse range of machinery across numerous sectors. It’s a testament to their fundamental utility in converting fluid power into mechanical work.

- Construction: Excavators, bulldozers, loaders, cranes, backhoes, dump trucks, concrete pumps – virtually every piece of heavy construction equipment relies on hydraulic cylinders for movement and operation.

- Manufacturing: Presses (stamping, forming), injection molding machines, robotic arms, clamping systems, material handling equipment.

- Agriculture: Tractors, combines, plows, loaders, balers – essential for controlling implements and performing various tasks.

- Material Handling: Forklifts, scissor lifts, pallet jacks, conveyor systems.

- Marine: Steering gears, deck cranes, hatch covers, winches on ships and offshore platforms.

- Automotive: Car lifts, brake systems (in some heavy vehicles), suspension systems in specialized vehicles.

- Aerospace: Landing gear retraction, flight control surfaces (in some aircraft).

- Mining: Drilling rigs, crushing equipment, shovels, haul trucks.

- Energy: Wind turbine pitch control, dam gate control, and oil and gas drilling equipment.

Relationship between Hydraulic Cylinders and Hydraulic Hose

The relationship between hydraulic cylinders and hydraulic hoses is fundamental to the proper functioning of hydraulic systems. We can understand their synergy as follows:

Power Transmission Medium: Hydraulic hoses are the “channels” through which high-pressure hydraulic fluid (usually hydraulic oil) is delivered from the hydraulic pump (power source) to the hydraulic cylinder. Without the hose, the hydraulic cylinder cannot receive the pressurized fluid needed to drive its movement.

Connection and Flexibility: Hydraulic hoses connect hydraulic cylinders to other parts of the hydraulic system, such as pumps, valves, and tanks. Due to their flexibility, hoses allow hydraulic cylinders to make relative movements when the machine is in operation, such as the extension and retraction of an excavator bucket or the raising and lowering of a crane arm, without damaging the piping system. If rigid piping is used, these movements will cause the pipes to break.

System Integrity: High-quality hydraulic hoses and appropriate fittings ensure the sealing of the hydraulic system, prevent high-pressure fluid leakage, thereby maintaining system pressure and ensuring that the hydraulic cylinder can output the required force and speed.

In short, the hydraulic cylinder is the component that performs the work, and the hydraulic hose is the lifeline that delivers the energy (in the form of pressurized hydraulic oil) required to drive this work to the hydraulic cylinder. They are an indispensable partner in hydraulic systems, together enabling the powerful functions and precise control of heavy machinery.

Common Troubleshooting Tips

| Problem | Possible Cause(s) |

| Slow Operation | Low fluid level, contaminated fluid, worn pump, internal leakage, restricted lines. |

| Loss of Power | Internal leakage (worn seals), low system pressure, relief valve malfunction, air in the system. |

| Jerky Movement | Air in the hydraulic system, insufficient fluid, worn seals, binding components. |

| External Leaks | Damaged seals, loose fittings, cracked cylinder barrel/hoses. |

| Overheating | Excessive friction, contaminated fluid, undersized components, continuous heavy load. |

| No Movement | No fluid supply, pump failure, blocked lines, control valve malfunction, major internal failure. |

Conclusion

In conclusion, the hydraulic cylinder is far more than just a simple mechanical component; it is the heart of countless machines that shape our modern world. From construction sites to manufacturing plants, and from farms to freight yards, these powerful actuators enable us to harness immense force with precision and reliability. As we continue to push the boundaries of engineering, we’re confident that the hydraulic cylinder will remain an indispensable tool, constantly evolving to meet the demands of an increasingly complex and automated future.