Hydraulic Oil Hose

Hydraulic oil hoses are the critical conduits that carry hydraulic fluid within a power system, enabling the transmission of energy to perform work. These hoses are engineered to withstand the demanding conditions of hydraulic applications, including high pressures, varying temperatures, and exposure to various petroleum-based or synthetic fluids. Their construction is vital for ensuring system integrity, efficiency, and safety across a wide array of industries, from heavy machinery to manufacturing equipment. Selecting the right hydraulic oil hose is paramount for reliable operation and preventing costly downtime.

Get Your Desired Hydraulic Oil Hose

Our factory specializes in high-performance hydraulic oil hoses, essential for transferring power in countless industrial and mobile applications. These hoses are expertly engineered to handle extreme pressures, diverse temperatures, and various hydraulic fluids, ensuring reliable and safe operation.

All Hydraulic Oil Hoses

High-Pressure Hydraulic Oil Hose

A high-pressure hydraulic oil hose is specifically engineered to operate safely and efficiently under immense fluid pressures, typically ranging from thousands of PSI up to tens of thousands. These hoses are critical components in heavy machinery and industrial systems where significant power transmission is required. Their robust construction, featuring multiple layers of high-tensile reinforcement, ensures unparalleled durability and burst resistance, minimizing the risk of leaks and catastrophic failures in the most demanding environments.

Low-Pressure Hydraulic Oil Hose

Low-pressure hydraulic oil hoses are designed for applications that require the transfer of hydraulic oil at lower pressures, typically down to a few hundred PSI. These hoses are commonly used in return, suction, and drain lines in hydraulic systems where the fluid can flow back to the tank without experiencing a significant pressure buildup. While they are not as rugged as high-pressure hoses, they are designed for durability, flexibility, and resistance to common hydraulic fluids, which is critical to maintaining system efficiency and preventing leaks in less demanding components in the circuit.

Hydraulic Oil Hose for Low-Temperature

Operating machinery in frigid climates requires hydraulic oil hoses that retain their flexibility and performance even in extreme cold. Our low-temperature hoses are manufactured with compounds specifically formulated to resist stiffening and embrittlement at sub-zero temperatures. This ensures that the hose remains pliable for easy installation and maintains its pressure rating without becoming brittle, which is crucial for equipment operating in arctic regions, cold storage facilities, or outdoor winter construction sites.

High-Temperature Hydraulic Oil Hose

In applications where hydraulic fluid or ambient conditions reach elevated temperatures, our specialized high-temperature hydraulic oil hoses are indispensable. These hoses feature inner tubes and outer covers made from materials designed to withstand prolonged exposure to heat without degrading, cracking, or losing structural integrity. Essential for engine compartments, steel mills, and other heat-intensive industrial settings, they ensure consistent performance and extend the lifespan of the hydraulic system, even under thermal stress.

Flexible Oil Resistant Hydraulic Hose

A flexible oil resistant hydraulic hose is specifically engineered to offer exceptional pliability while maintaining full integrity when exposed to various hydraulic fluids and oils. This type of hose is crucial in applications requiring tight bends, constant movement, or complex routing where traditional, stiffer hoses would fail or be impractical. Its advanced construction ensures superior flexibility without compromising its crucial resistance to oil degradation, thereby extending service life and providing reliable, adaptable performance in dynamic hydraulic systems.

Hydraulic Oil Hose for Flame Resistance

In environments with potential fire hazards, such as welding operations, foundries, or underground mining, our flame-resistant hydraulic oil hoses provide an added layer of safety. These hoses are constructed with materials that are self-extinguishing or designed to resist the propagation of flames. Meeting stringent safety standards, they help to prevent the spread of fire and protect personnel and equipment, making them a crucial choice in high-risk industrial settings where fire prevention is paramount.

Custom Hydraulic Oil Hose Wholesale

Hydraulic Oil Hose for Efficient Fluid Transfer

The primary function of any hydraulic oil hose is to facilitate the efficient transfer of hydraulic fluid from one point to another within a system. This fluid, under pressure, is the medium through which power is transmitted. A well-designed hose minimizes pressure drop and ensures smooth, consistent flow, which directly translates to responsive and powerful machinery operation. Our hoses are meticulously crafted with smooth inner bores to optimize flow characteristics, reducing energy loss and enhancing overall system efficiency in diverse applications from construction to agriculture.

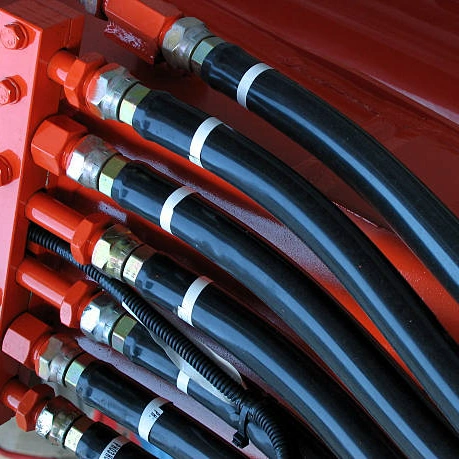

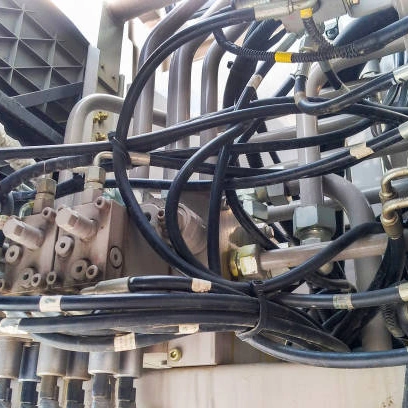

Hydraulic Oil Hose for Flexibility and Routing

Unlike rigid piping, a hydraulic oil hose offers essential flexibility, allowing for movement between components, absorbing vibrations, and simplifying installation in complex or confined spaces. This flexibility is crucial in dynamic applications where machinery parts move relative to each other. Our hoses are designed to accommodate tight bend radii without kinking or compromising performance, making them adaptable for diverse routing requirements in equipment where space is limited and movement is constant, ensuring smooth operation.

Hydraulic Oil Hose for Pressure Containment

One of the most critical aspects of a hydraulic oil hose is its ability to safely contain high internal pressures. Hydraulic systems often operate at thousands of PSI, and the hose must be robust enough to withstand these forces without bulging, leaking, or bursting. Our factory employs advanced reinforcement techniques, utilizing high-tensile materials, to ensure our hydraulic oil hoses maintain their structural integrity under extreme pressure fluctuations, providing a vital safety barrier and ensuring reliable power transmission in demanding environments.

Hydraulic Oil Hose for Environmental Resistance

A high-quality hydraulic oil hose must endure not only internal pressures but also external environmental challenges. This includes resistance to abrasion from external contact, resilience against temperature extremes, and protection from chemicals, UV radiation, and ozone. Our hoses feature durable outer covers that shield internal components from these harsh elements, extending their service life and ensuring consistent performance in challenging conditions, whether in an outdoor construction site or an indoor manufacturing plant.

What is the primary function of a hydraulic oil hose?

The main purpose of a hydraulic oil hose is to safely and efficiently transmit hydraulic fluid under pressure. This fluid acts as the medium for transferring power throughout a hydraulic system, enabling various components like cylinders and motors to perform work.

It’s engineered to withstand high pressures and maintain fluid integrity, ensuring reliable and precise operation of machinery and equipment in demanding industrial environments.

How do I choose the correct hydraulic oil hose for my application?

Selecting the right hydraulic oil hose requires considering several key factors: the system’s maximum operating pressure and temperature, the type of hydraulic fluid being used (for chemical compatibility), and the environmental conditions the hose will face (e.g., abrasion, UV exposure).

You also need to account for the required minimum bend radius and ensure proper fitting compatibility. Consulting with our technical team can help you make the optimal choice.

What causes a hydraulic oil hose to fail?

Common causes of hydraulic oil hose failure include exceeding the recommended working pressure or temperature, incorrect fluid compatibility leading to material degradation, and external damage such as severe abrasion, cuts, or kinking.

Improper installation, including twisting the hose or using incompatible fittings, can also significantly reduce its lifespan. Regular inspection and adherence to operating limits are crucial for prevention.

Can hydraulic oil hoses be repaired?

While minor external damage on some hydraulic oil hoses might seem repairable, it’s generally not recommended to repair high-pressure hydraulic hoses. The internal integrity of the hose, especially the reinforcement layers, can be compromised even without visible external signs.

For safety and system reliability, we strongly advise replacing a damaged hydraulic oil hose with a new one to prevent catastrophic failures and potential injuries.

What is the difference betweenhydraulic oil hose and hydraulic air hose?

The fundamental difference between a hydraulic oil hose and a hydraulic air hose (more commonly known as a pneumatic hose) lies in the medium they are designed to transport and the pressures they are built to withstand.

Hydraulic oil hoses are engineered for high-pressure applications, specifically designed to carry incompressible liquids like hydraulic oil. Their robust construction typically involves multiple layers of reinforcement (often braided or spiraled wire or synthetic fibers) to safely contain pressures that can reach several thousand PSI. This strength ensures efficient power transmission in heavy machinery.

In contrast, pneumatic hoses are designed to transport compressible gases, primarily compressed air, at much lower pressures, typically in the range of 100-200 PSI. While they also feature reinforcement, it’s generally less robust, focusing more on flexibility and lighter weight. Using a pneumatic hose in a high-pressure hydraulic oil system would lead to catastrophic failure due to its inability to contain the extreme forces involved.

Quote Hydraulic Oil Hose Wholesale

Is your project held back by unsuitable hydraulic hoses? Don’t compromise on performance or struggle with ill-fitting components. We offer 3/16 hydraulic hose wholesale, custom-tailored to your exact specifications. Get precise lengths, ideal pressure ratings, and the perfect fittings for seamless integration, ensuring your systems operate with maximum efficiency and reliability, every time.