Hydraulic hose flow rate is a critical factor in ensuring your hydraulic system runs efficiently and safely. It measures the volume of fluid moving through a hose over a specific time, affecting equipment performance and responsiveness. Understanding flow rate helps prevent pressure drops, overheating, and potential system failures.

Accurate knowledge of hydraulic hose flow rate allows operators to choose the right hose size, material, and configuration for each application. It also impacts energy efficiency and the longevity of hydraulic components. By monitoring and maintaining proper flow, businesses can reduce downtime, improve productivity, and protect expensive machinery from unnecessary wear.

What is the Hydraulic Hose Flow Rate?

Hydraulic hose flow rate refers to the volume of hydraulic fluid that passes through a hose in a specific amount of time. It’s a critical factor in determining the performance and efficiency of a hydraulic system.

Factors Affecting Hydraulic Hose Flow Rate

Hydraulic hose flow rate depends on several key factors that influence system performance and efficiency. Understanding these variables helps prevent pressure drops, hydraulic hose damage, and equipment wear. Properly considering them ensures your hydraulic system operates smoothly, safely, and reliably under various working conditions.

- Hydraulic Hose Diameter: Larger diameters allow more fluid to pass, reducing pressure drop, while smaller diameters restrict flow. Choosing the correct hydraulic hose size ensures efficient operation and prevents overloading pumps or other system components.

- Hydraulic Hose Length: Longer hydraulic hoses create more resistance, reducing flow rate and increasing pressure loss, while shorter hydraulic hoses improve efficiency but may limit flexibility. Proper length selection balances system layout with optimal flow.

- Fluid Viscosity: Thicker fluids resist movement, slowing flow and increasing pressure. Selecting hydraulic hoses compatible with fluid type and temperature range prevents heat buildup, excessive wear, and reduced performance.

- System Pressure: Higher operating pressures can increase flow, but exceeding hydraulic hose ratings risks leaks or bursts. Matching hydraulic hose specifications to system pressure ensures safe and consistent operation.

- Bends and Fittings: Sharp bends, kinks, or restrictive fittings in hydraulic hoses obstruct flow and reduce efficiency. Proper routing, gradual curves, and compatible fittings minimize pressure loss while extending hydraulic hose life.

Hydraulic Hose Size Flow Chart

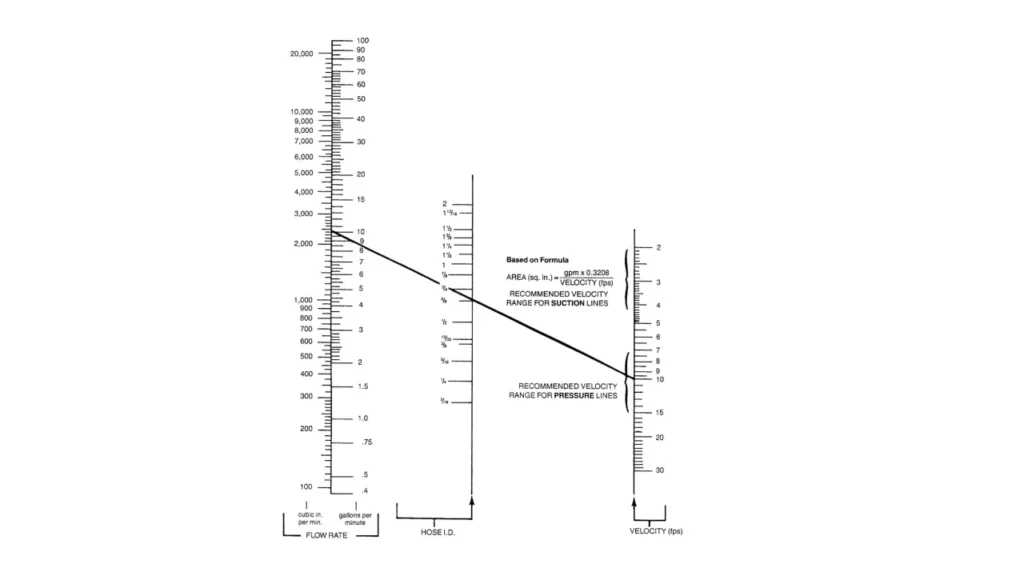

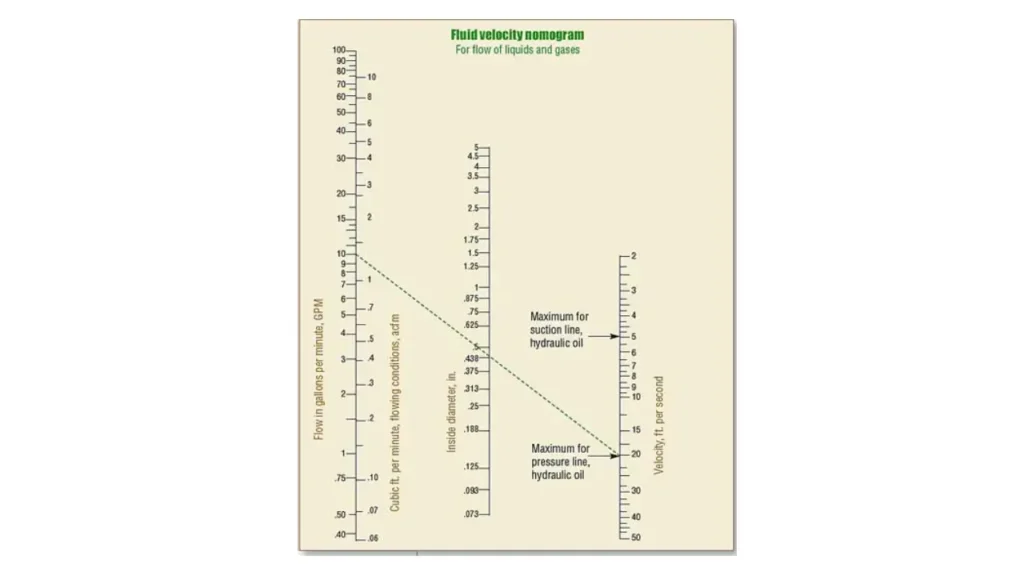

A hydraulic hose size flow chart, often referred to as a nomograph, is a visual tool used to determine the appropriate hose size based on the required flow rate and desired fluid velocity. It typically consists of three scales:

- Flow Rate: This scale represents the volume of fluid flowing through the hose per unit of time, usually measured in gallons per minute (GPM) or liters per minute (LPM).

- Hydraulic Hose Size: This scale indicates the inner diameter of the hose, often expressed in inches or millimeters.

- Fluid Velocity: This scale represents the speed at which the fluid is moving through the hose, measured in feet per second (FPS) or meters per second (m/s).

Approximate Flow Rates for Common Hydraulic Hose Sizes

Disclaimer: Actual flow rates can vary based on factors like fluid viscosity, system pressure, and hose length. This table provides a general estimate for typical hydraulic applications.

| Hydraulic Hose Size (in) | Approximate Flow Rate (GPM) |

|---|---|

| 1/2 hydraulic hose flow rate | 10-15 |

| 3/4 hydraulic hose flow rate | 20-30 |

| 3/8 hydraulic hose flow rate | 5-10 |

Note: For more precise calculations and specific applications, it’s recommended to consult hydraulic engineering resources or use specialized software tools.

Why the Variation?

- Fluid Viscosity: Thicker fluids, like hydraulic oil, will flow slower than thinner fluids.

- System Pressure: Higher pressure can increase flow rate, but it’s important to consider the hose’s pressure rating.

- Hose Length: Longer hoses can increase frictional losses, reducing flow rate.

- Bends and Fittings: These can create additional flow restrictions.

How to Use a Hydraulic Hose Size Flow Chart?

A hydraulic hose size flow chart helps you match flow rate, velocity, and hydraulic hose diameter for safe and efficient system performance. Using the chart correctly prevents excessive pressure drop, overheating, and premature hydraulic hose failure. Understanding how to read and apply the data ensures your hydraulic system runs smoothly and reliably.

- Identify the Required Flow Rate: Start by determining your system’s flow rate, usually measured in gallons per minute (GPM) or liters per minute (LPM). This value typically comes from pump specifications or system design documents. Accurate flow rate data is essential before referencing the hydraulic hose size flow chart.

- Locate the Recommended Velocity Range: Hydraulic systems have recommended fluid velocity ranges for pressure lines, return lines, and suction lines. Using the hydraulic hose size flow chart, find the velocity band that matches your application to prevent turbulence, noise, excessive heat generation, and long-term hydraulic hose wear.

- Match Flow Rate to Hydraulic Hose Diameter: Once flow rate and velocity range are known, follow the chart to identify the correct hydraulic hose inside diameter. Selecting a diameter that keeps velocity within acceptable limits ensures balanced performance, energy efficiency, and reduced stress on system components.

- Check Pressure Rating Compatibility: After selecting the hydraulic hose diameter from the flow chart, confirm that the hydraulic hose pressure rating meets or exceeds your system’s maximum operating pressure. This step ensures safety, prevents hydraulic hose rupture, and maintains reliable system operation.

- Verify Installation Conditions: Finally, consider hydraulic hose length, routing, bend radius, and fittings. Even if the hydraulic hose size flow chart indicates the correct diameter, poor installation can restrict flow and reduce efficiency. Proper routing supports optimal flow and extends hydraulic hose service life.

Hydraulic Hose Flow Rate Calculator

Before we delve into the calculation, it’s crucial to grasp the fundamental factors influencing hydraulic hose flow rate:

- Hose Diameter: A larger diameter allows for higher flow rates.

- Fluid Viscosity: Thicker fluids flow slower than thinner ones.

- System Pressure: Higher pressure can increase flow rate, but it’s important to consider the hose’s pressure rating.

- Hose Length: Longer hoses can increase frictional losses, reducing flow rate.

The Formula

While a precise calculation often requires specific hydraulic system data and fluid properties, a simplified formula can provide a general estimate:

Flow Rate (GPM) = (π/4) × (Diameter²) × Velocity

Where:

- GPM: Gallons per minute

- π: Pi (approximately 3.14159)

- Diameter: Inner diameter of the hose in inches

- Velocity: Fluid velocity in feet per second

Using Online Calculators

For more accurate calculations, consider using online tools provided by hydraulic component manufacturers or engineering software. These tools often incorporate additional factors like fluid viscosity, pressure drop, and hose material to provide more precise results.

Important Considerations

- Hose Material: Different hose materials have varying flow characteristics.

- Bends and Fittings: These can significantly impact flow rate, especially with sharp bends.

- Fluid Contamination: Contaminants can increase fluid viscosity and reduce flow rate.

- Temperature: Temperature affects fluid viscosity, which in turn affects flow rate.

Remember:

While these calculations and online tools can provide valuable insights, it’s always recommended to consult with hydraulic experts or refer to specific manufacturer‘s guidelines for precise calculations tailored to your specific application.

Would you like to use a specific online calculator or do you have a particular hydraulic system in mind that you’d like to calculate the flow rate for?

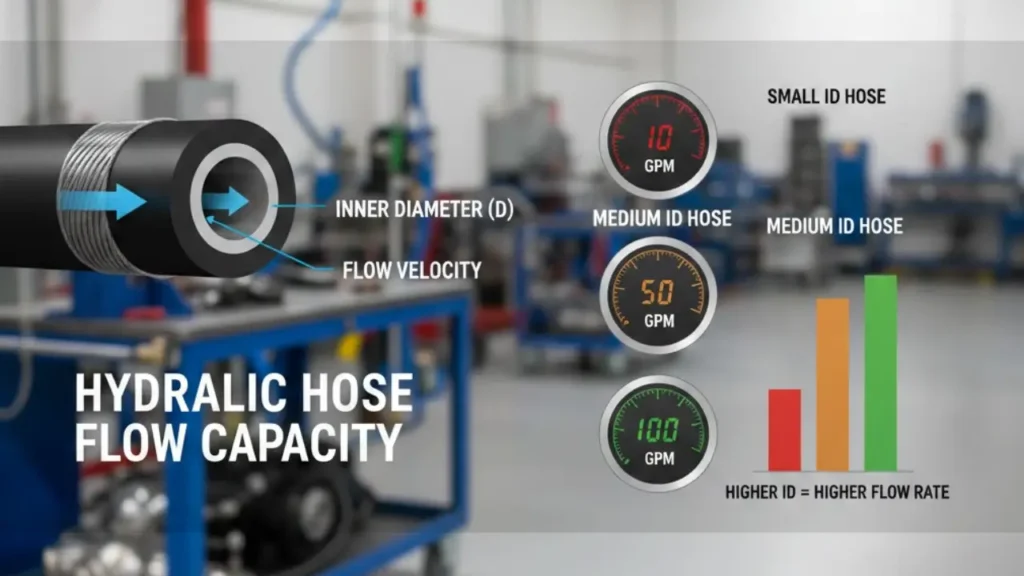

Hydraulic Hose Flow Capacity

The flow capacity of a hydraulic hose, often measured in gallons per minute (GPM) or liters per minute (LPM), is determined by several factors:

- Hose Diameter: A larger diameter hose can accommodate a higher flow rate.

- Fluid Viscosity: Thicker fluids (higher viscosity) flow more slowly than thinner fluids.

- System Pressure: Higher pressure can increase flow rate, but it’s essential to consider the hose’s pressure rating.

- Hose Length: Longer hoses can increase frictional losses, reducing flow rate.

- Bends and Fittings: These can create additional flow restrictions.

Factors Affecting Flow Capacity:

- Fluid Velocity: High fluid velocity can cause turbulence, leading to increased pressure drop and energy loss.

- Hose Material: Different hose materials have varying flow characteristics.

- Fluid Contamination: Contaminants can increase fluid viscosity and reduce flow rate.

- Temperature: Temperature affects fluid viscosity, which in turn affects flow rate.

Calculating Flow Capacity:

While a simplified formula can provide a general estimate, for accurate calculations, it’s best to use online tools or consult with hydraulic experts. These tools often incorporate additional factors like fluid viscosity, pressure drop, and hose material to provide more precise results.

Online Calculators:

- Gates Fluid Flow Pressure Calculator: https://www.gates.com/us/en/knowledge-center/calculators/fluid-flow-pressure-calculator.html

- Copley Developments Flow Rate Calculator: https://www.copely.com/tools/flow-rate-calculator/

- OneHydraulics Line Sizing Calculator: https://www.onehydraulics.com/pages/hydraulic-line-sizing-calculator-page

Important Considerations:

- Hose Selection: Choose a hose with a suitable diameter and pressure rating for your specific application.

- Installation: Proper installation, including minimizing bends and using appropriate fittings, is crucial.

- Maintenance: Regular maintenance, including cleaning and inspection, can help maintain optimal flow capacity.

By carefully considering these factors and selecting the appropriate hose, you can ensure the efficient and reliable operation of your hydraulic system.

Conclusion

Understanding the hydraulic hose flow rate is crucial for optimizing the performance and efficiency of your hydraulic systems. By carefully considering factors like hose diameter, fluid viscosity, and pressure, you can select the right hose for your specific application.

Ready to upgrade your hydraulic systems with high-quality, high-performance hydraulic hoses?

Contact us today to explore our extensive range of wholesale hydraulic hoses. Our expert team is dedicated to providing you with the best products and services to meet your unique needs.

Don’t compromise on performance. Choose [Your Company Name] for all your hydraulic hose requirements.