Hydraulic hose clamps are essential components in any hydraulic system. They play a crucial role in ensuring the secure and leak-proof connection of hydraulic hoses, preventing fluid loss and system failure. In this comprehensive guide, we will delve into the world of hydraulic hose clamps, exploring their types, applications, and the factors to consider when selecting the right clamp for your specific needs.

Whether you’re a seasoned hydraulics professional or a DIY enthusiast, understanding the intricacies of hydraulic hose clamps is essential for maintaining the optimal performance and longevity of your hydraulic system.

What Are Hydraulic Hose Clamps

Hydraulic hose clamps are mechanical devices used to secure hydraulic hoses to fittings, preventing leaks and ensuring a secure connection. They are essential components in hydraulic systems, as they provide the necessary clamping force to hold hoses in place, even under high-pressure conditions.

What are Hydraulic Hose Clamps Made of?

Hydraulic hose clamps are constructed from a range of materials chosen for their strength, durability, and resistance to environmental factors like temperature, chemicals, and corrosion. The material selection is key to matching the clamp’s performance to the operational demands of the system.

We supply clamps made from high-grade materials that ensure long-term reliability and structural integrity in demanding applications.

- Steel and Stainless Steel: Steel is widely used for its superior strength and rigidity, making it suitable for high-vibration and heavy-duty environments. Stainless steel (like 304 or 316) offers excellent corrosion resistance, making it ideal for marine, chemical, or outdoor applications where moisture and harsh elements are present. We offer metallic clamps for maximum load bearing.

- Polypropylene and Polyamide (Nylon): These durable, lightweight plastics are often used for clamp bodies where vibration dampening and chemical resistance are necessary. Polypropylene offers good chemical stability, while Nylon provides greater mechanical strength. Both are non-conductive and frequently used in modular stacking systems. We manufacture polymer options for weight and corrosion advantages.

- Aluminum: Aluminum clamps are selected when a balance of strength and reduced weight is required, particularly in mobile equipment applications. They offer good resistance to rust and can be machined for precise fitting, providing a robust and lighter alternative to steel in certain hydraulic setups. We supply aluminum clamps to reduce overall system mass.

- Elastomers (Rubber/Thermoplastic): Many clamps, especially P-clips, feature an inner cushion or lining made of an elastomeric material like EPDM or rubber. This soft lining absorbs shock, reduces noise, and protects the hose’s outer cover from direct abrasion against the rigid clamp body. We provide cushioned clamps for enhanced protection and stability.

Hydraulic Hose Clamp Types

Here are some common types of hydraulic hose clamps:

Worm Gear Clamps

Worm gear clamps are the most common type of hydraulic hose clamp. They consist of a band with teeth that mesh with a worm gear. By turning the worm gear, the band tightens around the hose, providing a secure grip.

Worm gear clamps are versatile and can be used in a wide range of applications. They are relatively easy to install and remove, making them a popular choice for many hydraulic systems. However, they may not be suitable for high-pressure or high-vibration applications, as the clamping force can diminish over time.

T-Bolt Clamps

T-bolt clamps offer a high clamping force and are ideal for high-pressure applications. They consist of a band with a T-shaped bolt that passes through the band and is tightened with a nut.

T-bolt clamps provide a secure and reliable connection, but they can be more difficult to install and remove than worm gear clamps. They are often used in critical applications where a high level of safety and reliability is required.

Ear Clamps

Ear clamps, also known as Oetiker or pinch clamps, are a type of clamp that uses a crimping tool to create a secure and tamper-resistant connection. They are often used in automotive and aerospace applications, where reliability and safety are paramount.

Ear clamps offer excellent vibration resistance and can withstand high pressures. However, they require a specialized crimping tool for installation, which can limit their use in some applications.

Spring Clamps

Spring clamps use a spring mechanism to provide clamping force. They are often used in automotive applications, where they are easy to install and remove.

Spring clamps are suitable for low-pressure applications and are often used to secure hoses to fittings in engine compartments and under the hood. However, they may not be suitable for high-pressure or high-vibration applications, as the spring tension can diminish over time.

Quick-Release Clamps

Quick-release clamps allow for rapid connection and disconnection of hoses. They are often used in applications where frequent assembly and disassembly are required.

Quick-release clamps are convenient and can save time, but they may not be as durable as other types of clamps. They are typically used in low-pressure applications and may not be suitable for high-pressure or high-vibration environments.

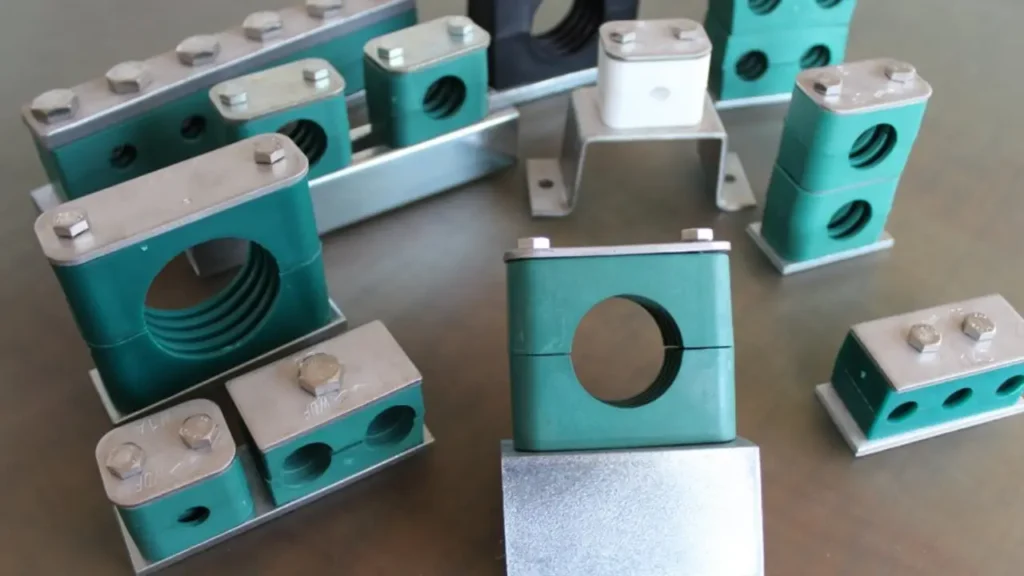

Hydraulic Hose Routing Clamps

Hydraulic hose routing clamps are specifically designed to secure and route hydraulic hoses in a specific way. They are often used to prevent hose chafing, kinking, and interference with other components.

Key Functions of Hydraulic Hose Routing Clamps:

- Protect Hoses: They shield hoses from damage caused by vibration, abrasion, and heat.

- Maintain Hose Integrity: By keeping hoses organized and secure, they help maintain their structural integrity.

- Improve System Aesthetics: They can help to tidy up the appearance of a hydraulic system.

Types of Hydraulic Hose Routing Clamps:

- Strap Clamps: These clamps use a strap or band that is tightened around the hose to secure it to a surface.

- Cable Ties: While not specifically designed for hydraulic hoses, cable ties can be used to bundle and route hoses, especially in low-pressure applications.

- Hose Clips: These clips are designed to attach hoses to specific surfaces, such as engine blocks or chassis frames.

- Hose Clamps with Integrated Routing: Some hose clamps have built-in features to guide and route hoses, such as channels or clips.

Factors to Consider When Choosing Hydraulic Hose Routing Clamps:

- Hose Size and Type: The clamp must be compatible with the size and type of hose.

- Environmental Conditions: The clamp should be resistant to the specific environmental conditions, such as temperature, humidity, and chemical exposure.

- Vibration and Shock: The clamp should be able to withstand vibration and shock, especially in mobile applications.

- Ease of Installation: The clamp should be easy to install and remove.

- Aesthetics: The clamp should be visually appealing and not detract from the overall appearance of the machine or equipment.

By using hydraulic hose routing clamps, you can improve the reliability and lifespan of your hydraulic system, reduce maintenance costs, and enhance the overall performance of your equipment.

What Are Hydraulic Hose Clamps Used for

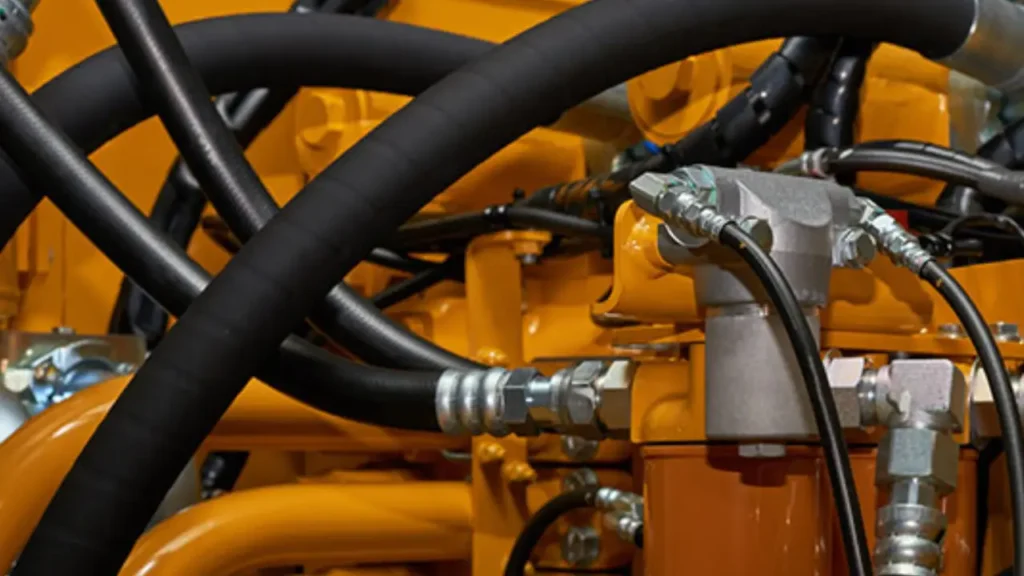

Hydraulic hose clamps are essential components used across virtually all fluid power systems to manage and protect flexible hoses. Their primary function is to secure lines and ensure they are routed correctly, which is vital for preventing premature wear and operational failure in demanding applications.

By maintaining proper spacing and position, these clamps keep your machinery running efficiently and safely. We supply these robust components for optimal system integrity.

- Prevents Abrasion and Wear By isolating the hose from contact with other components, sharp edges, or moving parts, the clamp eliminates chafing. This prevents the outer cover from wearing down, which exposes the reinforcement layers and can lead to a costly, sudden hose burst. We offer protection that drastically extends the hose’s service life and reliability.

- Ensures Correct Routing and Alignment The clamp guides the hose along its intended path, guaranteeing the bend radius limits are respected and preventing kinking or excessive stress on the line. Correct alignment reduces strain on fittings, preserving the seal integrity and stopping potential leaks. We manufacture reliable accessories to maintain system safety and efficiency.

- Reduces Vibration and Movement In heavy-duty applications, constant vibration and motion can loosen fittings and accelerate material fatigue. Hose clamps firmly secure the lines, dampening movement and minimizing dynamic stress on the hose structure. This stability contributes to a more reliable and quieter operation. We provide solutions for enhanced operational stability and safety.

- Organizes and Protects the System Using clamps leads to a cleaner, more organized hose layout, making inspection and maintenance simpler and quicker. They keep hoses out of harm’s way, protecting them from external impact damage from debris or machinery. We supply components that safeguard your valuable investment in hydraulic hoses.

How to Clamp Hydraulic Hoses

Clamping hydraulic hoses correctly is essential for system safety, preventing line movement, abrasion, and premature failure. The right clamping procedure ensures the hose maintains its intended routing and bend radius, maximizing its service life. We provide the following steps to ensure you install our clamps properly and achieve optimal, reliable hose management in your fluid power systems.

Tools Needed:

- Drill and appropriate bits

- Wrenches or sockets

- Measuring tape

- Torque wrench

Step 1: Determine Clamp Location and Spacing

Begin by determining the precise location and spacing needed for each clamp along the hose’s path. Clamps should be placed near fittings, bend points, and at regular intervals (typically every 18-24 inches) on straight runs. This ensures consistent support, prevents hose slack, and minimizes dynamic movement under pressure changes. We recommend following manufacturer guidelines for maximum stability and support.

Step 2: Prepare the Mounting Surface

The mounting surface must be clean, flat, and structurally sound to accept the clamp. Mark the mounting holes according to the clamp’s size and design, then drill the holes if necessary. Ensure that any mounting hardware (like bolts or screws) is the correct length and strength to secure the clamp firmly against the frame. We advise using quality hardware for a secure and lasting installation.

Step 3: Install the Clamp and Secure the Hose

Place one half of the clamp (or the base of a P-clip) onto the prepared surface and loosely install the mounting hardware. Position the hydraulic hose correctly within the clamp body, ensuring it’s not twisted or strained. Then, install the second half of the clamp (if applicable), making sure the hose sits snugly within the groove. We manufacture clamps for an ideal hose fit.

Step 4: Tighten the Mounting Hardware

Finally, securely tighten all mounting bolts or screws. Use a torque wrench to apply the manufacturer’s specified torque rating to prevent overtightening, which can damage the clamp or the hose, or undertightening, which allows slippage. The hose must be held firmly but should not be deformed. We provide specifications to achieve maximum holding power and safety.

How to Choose the Right Hydraulic Hose Clamps?

Choosing the right hydraulic hose clamp is a crucial decision that directly impacts the safety and longevity of your hydraulic system. The selection process must carefully consider the operating environment, the hose specifications, and the mechanical forces the clamp must manage.

We guide our clients through these factors to ensure they select the most appropriate and durable solution for their specific applications, guaranteeing system integrity.

- Consider the Hose Size and Quantity: The clamp must match the hose’s outer diameter precisely to ensure a secure, firm grip without causing undue compression or allowing slippage. If your setup requires managing multiple lines in proximity, opting for modular or stackable clamp systems is the best choice. We supply clamps with accurate dimensions for a perfect fit and enhanced stability.

- Evaluate the Operational Environment: Hose clamps must withstand the conditions of use, including temperature extremes, exposure to corrosive fluids, and moisture. We recommend materials like stainless steel or specific chemical-resistant polymers for harsh settings to ensure the clamp maintains its strength and functionality. We manufacture materials for maximum resistance and long-term performance.

- Assess Vibration and Dynamic Stress: For systems experiencing high vibration, shock, or repetitive movement, selecting a cushioned clamp (like a P-clip with an elastomer lining) is necessary. The cushioning absorbs impact, protects the hose cover from abrasion, and provides superior noise reduction. We provide dampening solutions for challenging mobile equipment applications.

- Check Mounting Surface and Accessibility: Determine the type of surface the clamp will attach to and the installation method required (e.g., bolting, welding). Consider future maintenance—some locations benefit from easy-access clamps. Choose a style that allows for secure, hassle-free mounting while optimizing space. We offer various styles for flexible installation needs and reliability.

Conclusion

Hydraulic hose clamps play a crucial role in ensuring the safety and reliability of hydraulic systems. By understanding the different types of clamps, their applications, and proper installation techniques, you can significantly reduce the risk of leaks, failures, and accidents.

Ready to optimize your hydraulic systems?

Explore our extensive range of high-quality wholesale hydraulic hoses, designed to meet the demands of diverse industries. From construction and agriculture to manufacturing and mining, our hoses offer exceptional durability, flexibility, and resistance to extreme pressures and temperatures.

Contact us today to discuss your specific needs and discover how our hydraulic hoses can empower your operations.