Hydraulic hoses are the lifeblood of many industrial machines, powering everything from construction equipment to manufacturing processes. However, these essential components are susceptible to various forms of damage, including blistering. This seemingly minor issue can lead to significant problems, including hydraulic fluid leaks, reduced system performance, and even catastrophic failures.

In this blog, we will explore the world of hydraulic hose blistering, its causes, consequences, and prevention strategies.

What is Hydraulic Hose Blistering?

Hydraulic hose blistering is a condition where small bubbles or blisters form on the outer surface of a hydraulic hose.

This often indicates internal damage or deterioration of the hose material.

Causes of Hydraulic Hose Blistering:

- Incompatible fluids: If the hydraulic fluid used is not compatible with the hose material, it can cause the fluid to permeate the hose wall and form blisters.

- High temperatures: Excessive heat can degrade the hose material, leading to blistering and potential failure.

- Chemical exposure: Exposure to certain chemicals can weaken the hose material and cause blistering.

- Internal pressure: High internal pressure can force fluid or gas through the hose wall, resulting in blisters.

Consequences of Hydraulic Hose Blistering:

- Fluid leaks: Blisters can weaken the hose wall, leading to leaks and fluid loss.

- Reduced performance: A damaged hose can restrict fluid flow, affecting the performance of hydraulic systems.

- System failure: In severe cases, blistering can lead to complete hose failure, causing equipment downtime and potential safety hazards.

Prevention and Maintenance:

- Use compatible fluids: Ensure that the hydraulic fluid used is compatible with the hose material.

- Monitor temperatures: Avoid exposing hoses to excessive heat.

- Inspect regularly: Conduct regular inspections of hoses for signs of blistering, cracking, or other damage.

- Replace damaged hoses promptly: Replace any damaged or worn hoses immediately.

- Proper storage: Store hoses in a cool, dry place, away from direct sunlight and harmful chemicals.

By taking these preventive measures, you can significantly reduce the risk of hydraulic hose blistering and ensure the reliable operation of your hydraulic systems.

Why Is the Hydraulic Hose Blistering

Hydraulic hose blistering occurs due to a variety of factors, often related to the degradation or incompatibility of the hose material with the fluid or environmental conditions. Here are the primary causes:

1. Incompatible Fluids:

- Chemical Reaction: If the hydraulic fluid is incompatible with the hose material, it can cause a chemical reaction that weakens the hose wall.

- Fluid Permeation: The fluid may penetrate the hose wall, leading to the formation of blisters on the surface.

2. Excessive Heat:

- Thermal Degradation: High temperatures can accelerate the aging process of the hose material, making it more susceptible to blistering.

- Fluid Vaporization: Heat can cause the fluid to vaporize, creating pressure within the hose and leading to blistering.

3. Chemical Exposure:

- Chemical Attack: Exposure to certain chemicals, such as solvents or acids, can weaken the hose material and cause it to blister.

4. Internal Pressure:

- Pressure Fluctuations: Sudden pressure spikes or surges can stress the hose wall, leading to the formation of blisters.

- Gas Ingestion: If gas is introduced into the hydraulic system, it can accumulate within the hose and cause blistering.

5. Improper Installation and Maintenance:

- Kinking and Bending: Excessive bending or kinking of the hose can weaken the hose wall.

- Abrasion: Rubbing against other components can cause damage to the hose and lead to blistering.

- Neglect: Failure to inspect and replace hoses regularly can lead to premature failure and blistering.

By understanding these causes, you can take steps to prevent hydraulic hose blistering and ensure the reliable operation of your hydraulic systems.

How to Fix Hydraulic Hose Blistering

We must address hydraulic hose blistering immediately to maintain system safety and performance. These blisters usually indicate that the inner tube has failed, allowing pressurized fluid to seep into the reinforcement layers. By following our systematic approach, you can identify the source of the failure, replace the damaged components, and implement preventative measures to stop future issues.

Tools Needed

- Replacement hydraulic hose assembly

- Calibrated torque wrench

- Hose cutting tool or fine-tooth saw

- Cleaning rags and solvent

- Safety goggles and heavy-duty gloves

- Pin-pricking tool (if applicable)

Step 1: Inspect The Damage

We start by identifying every blister along the hose length to gauge the severity of the internal leak. You should look for small bubbles or large bulges that indicate fluid is trapped under the outer cover. This visual check helps us determine if the issue is localized or spread across the entire system.

You must never prick the blisters while the hose is under pressure as this causes dangerous fluid injection. We recommend checking the surrounding environment for heat sources or chemical spills that might have weakened the rubber. Understanding the external conditions allows us to choose a more durable replacement for your specific application.

Step 2: Relieve System Pressure

We must ensure the hydraulic system is completely powered down before you attempt any repairs or removals. You should cycle the control valves several times to bleed off any residual pressure trapped within the lines. This safety step prevents accidental fluid discharge that can cause serious injury or environmental contamination during work.

After the pressure is zero, we double-check the gauges to verify that the circuit is safe to open. You should place a collection container beneath the fittings to catch any draining oil as you loosen the connections. Keeping the workspace clean prevents slips and keeps contaminants from entering the open hydraulic ports.

Step 3: Remove The Failed Hose

We use two wrenches to loosen the fittings to prevent twisting the metal tubes or damaging the manifold ports. You should carefully pull the hose away from its routing, noting any tight bends or abrasive contact points that could have contributed to the failure. This removal process provides a clear view of the fittings.

Once the hose is out, we suggest inspecting the internal tube at the ends for signs of chemical erosion. You can compare the old hose specifications with your system requirements to ensure the original part was correctly rated. Documenting these findings helps us avoid installing another incompatible component that would blister again shortly.

Step 4: Install The Correct Replacement

We select a new hose that is fully compatible with your hydraulic fluid and the operating pressure of the pump. You should ensure the replacement has a perforated cover if you are transporting air or gases to prevent future gas accumulation. Proper selection is the most critical step in ensuring long-term reliability for you.

Align the new hose carefully to avoid any sharp bends or twisting during the final tightening of the end fittings. You should use a torque wrench to meet the manufacturer specifications, ensuring a leak-free seal without over-stressing the threads. A well-installed hose reduces the risk of vibration damage and premature outer cover wear.

Step 5: Test And Monitor Performance

We restart the system at low pressure to check for initial leaks around the new connections and the hose. You should gradually increase the load while watching the hose for any signs of abnormal expansion or heat buildup. This controlled startup phase confirms that the new assembly is handling the required hydraulic force.

Regular inspections should be scheduled to catch early signs of wear before another blister can form on the cover. You can add protective sleeves if the hose is exposed to high external temperatures or constant friction against the machine frame. Consistent monitoring ensures your equipment stays operational and avoids expensive emergency repairs in the future.

Guidelines For Hydraulic Hose Replacement

Proper hydraulic hose replacement is essential for system safety, efficiency, and longevity. Regular inspection, timely replacement, and correct installation prevent leaks, system failures, and downtime. Following clear procedures ensures hoses perform reliably under pressure, temperature, and environmental conditions in industrial, construction, agricultural, and mobile hydraulic applications.

- Inspect Hoses Regularly – Check for cracks, abrasion, leaks, or bulges. Regular inspections help identify worn or damaged hoses early, preventing unexpected failures and maintaining smooth hydraulic system operation.

- Select Compatible Hoses – Choose hoses that match pressure ratings, fluid type, temperature range, and length requirements. Correct selection ensures safe operation, prevents premature wear, and maintains fluid flow efficiency.

- Use Proper Fittings – Ensure fittings and connectors are compatible with the hose and system ports. Correct installation prevents leaks, maintains hydraulic pressure, and reduces the risk of hose detachment during operation.

- Follow Correct Installation Procedures – Avoid twisting, kinking, or stretching hoses during installation. Proper routing, bend radius, and support prevent damage, ensure smooth fluid flow, and extend hose service life.

- Test After Replacement – After installing a new hose, operate the system at low pressure first to check for leaks or abnormalities. This ensures safe and reliable performance before full operation.

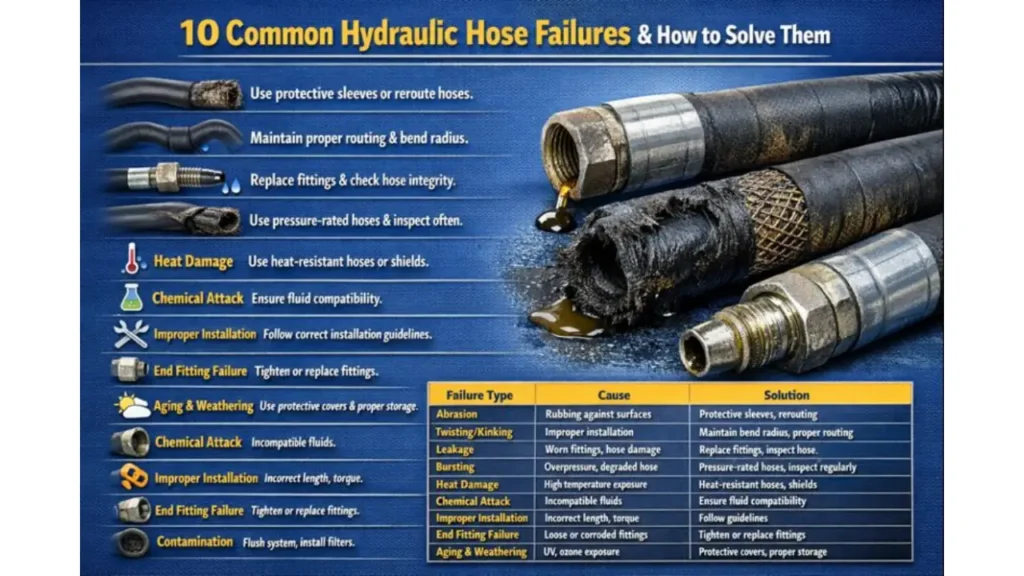

10 Common Hydraulic Hose Failures & How to Solve Them

Hydraulic hoses are critical for safe and efficient system operation, but failures can occur due to wear, improper installation, or environmental factors. Identifying common issues and applying correct solutions helps prevent downtime, reduce maintenance costs, and extend hose life in industrial, construction, agricultural, and mobile hydraulic systems.

- Abrasion – Caused by rubbing against surfaces; solved by adding protective sleeves or rerouting hoses.

- Twisting/Kinking – Occurs during installation or operation; prevent by maintaining proper bend radius and hose routing.

- Leakage – Due to worn fittings or damaged hydraulic hoses, replace fittings and inspect hose integrity.

- Bursting – From overpressure or degraded hose; choose hoses rated for system pressure and inspect regularly.

- Heat Damage – Exposure to high temperatures; use heat-resistant hoses or shields.

- Chemical Attack – Incompatible fluids can degrade hose material; ensure fluid compatibility.

- Improper Installation – Incorrect length or fitting torque; follow manufacturer installation guidelines.

- End Fitting Failure – Loose or corroded fittings; tighten or replace with corrosion-resistant options.

- Aging and Weathering – UV or ozone exposure; store hoses properly and use protective covers.

- Contamination – Dirt or debris inside the hydraulic hose; flush system regularly and install proper filters.

| Failure Type | Cause | Solution |

|---|---|---|

| Abrasion | Rubbing against surfaces | Protective sleeves, rerouting |

| Twisting/Kinking | Improper installation or routing | Maintain bend radius, correct routing |

| Leakage | Worn fittings or hose damage | Replace fittings, inspect hose |

| Bursting | Overpressure or degraded hose | Use proper pressure-rated hoses, inspect regularly |

| Heat Damage | High temperature exposure | Heat-resistant hoses or shields |

| Chemical Attack | Incompatible fluids | Ensure fluid compatibility |

| Improper Installation | Wrong length, incorrect torque | Follow installation guidelines |

| End Fitting Failure | Loose or corroded fittings | Tighten or replace fittings |

| Aging and Weathering | UV, ozone, environmental exposure | Protective covers, proper storage |

| Contamination | Dirt or debris inside hose | Flush system, install filters |

Conclusion

While often overlooked, hydraulic hose blistering is a serious issue that can lead to significant problems for your machinery. By understanding the causes and consequences of this condition, you can take proactive steps to prevent it and extend the life of your hydraulic hoses.

- Regular inspections: Conduct routine inspections of your hydraulic hoses for signs of blistering and other damage.

- Proper installation: Ensure that your hoses are installed correctly to avoid stress and strain.

- High-quality hoses: Invest in high-quality hydraulic hoses from reputable manufacturers.

- Avoid excessive heat and cold: Extreme temperatures can accelerate the aging process of hoses.

- Proper storage: Store hoses in a cool, dry place, away from direct sunlight and harmful chemicals.

Ready to upgrade your hydraulic system with blister-resistant hoses?

Contact us today to explore our extensive range of wholesale hydraulic hoses. Our expert team can help you select the right hoses for your specific application and provide valuable advice on maintenance and best practices.

Don’t let blistering compromise your machinery’s performance. Take action now and safeguard your investment.