Hydraulic hoses are essential components in countless industrial, agricultural, and automotive applications. They are responsible for transporting high-pressure hydraulic fluid to various components, powering everything from heavy machinery to delicate precision tools. When it comes to hydraulic systems, selecting the right hose size is crucial for optimal performance, safety, and longevity.

In this blog post, we will delve into the world of hydraulic hose sizes, exploring factors such as hydraulic hose diameter, length, pressure ratings, and compatibility with different fluids.

We will also discuss the importance of proper hose selection and provide practical tips for making informed decisions. By the end of this guide, you will have a solid understanding of how to choose the perfect hydraulic hose for your specific needs.

What is Hydraulic Hose Sizing

Hydraulic hose sizing refers to the process of selecting the appropriate size of hydraulic hose for a specific application. The size of a hydraulic hose is typically determined by its inner diameter (ID), which is the measurement of the empty space inside the hose. The ID affects the flow rate of the fluid within the hose, while the outer diameter (OD) helps to determine appropriate fittings and system components.

Several factors need to be considered when sizing a hydraulic hose, including:

- Flow rate: The volume of fluid that needs to be transported through the hose per unit of time.

- Pressure rating: The maximum pressure that the hose can withstand without failing.

- Temperature range: The temperature range that the hose will be exposed to during operation.

- Fluid compatibility: The type of fluid that will be flowing through the hose and its compatibility with the hose material.

- Hose length: The distance between the two end points of the hose.

Hydraulic hose sizing is typically done using a nomograph, which is a chart that helps to determine the appropriate hose size based on the flow rate, pressure, and other factors. It is important to consult with a hydraulic hose expert or refer to manufacturer guidelines for precise recommendations.

Incorrect hose sizing can lead to several problems, including:

- Reduced system performance: If the hose is too small, it can restrict the flow of fluid, leading to reduced system performance.

- Increased pressure drop: A smaller hose can also cause a significant pressure drop, which can affect the operation of hydraulic components.

- Hose failure: If the hose is not sized correctly, it may fail prematurely, leading to leaks, spills, and potential injuries.

By properly sizing hydraulic hoses, you can ensure the optimal performance and safety of your hydraulic system.

What Causes Incorrect Hydraulic Hose Sizes

Several factors can lead to incorrect hydraulic hose sizing:

Human Error:

- Miscalculations: Incorrect calculations of flow rate, pressure, or other parameters can lead to the selection of an inappropriate hose size.

- Misreading specifications: Misinterpreting system specifications or manufacturer guidelines can result in incorrect hose selection.

- Lack of expertise: Insufficient knowledge or experience in hydraulic systems can lead to poor sizing decisions.

System Changes:

- Modifications: Changes to the hydraulic system, such as adding components or increasing pressure, may require a different hose size.

- Wear and Tear: Over time, hydraulic components can wear out, leading to increased pressure or flow requirements that may necessitate a larger hose size.

Supply Chain Issues:

- Availability: If the correct hose size is not readily available, a substitute with a different size may be used as a temporary solution.

- Cost considerations: In some cases, cost-saving measures may lead to the selection of a smaller or less expensive hose, even if it’s not the ideal size.

Incorrect Assumptions:

- Overestimating or underestimating requirements: Assuming that a particular hose size will be sufficient without proper calculations can lead to issues.

- Neglecting factors: Ignoring factors like temperature, fluid compatibility, and vibration can result in premature hose failure.

To avoid incorrect hydraulic hose sizing, it is crucial to:

- Consult with our hydraulic hose experts: Seek advice from our hydraulic system engineers or experienced technicians.

- Use accurate calculations: Employ reliable formulas and software to determine the appropriate hose size.

- Consider system requirements: Account for all relevant factors, including pressure, flow rate, temperature, and fluid compatibility.

- Verify manufacturer specifications: Ensure that the selected hose meets or exceeds the system’s requirements.

- Regularly inspect hoses: Monitor the condition of hoses and replace them as needed to prevent failures.

By taking these precautions, you can minimize the risk of incorrect hydraulic hose sizing and ensure the optimal performance and safety of your hydraulic system.

Hydraulic Hose Size Components

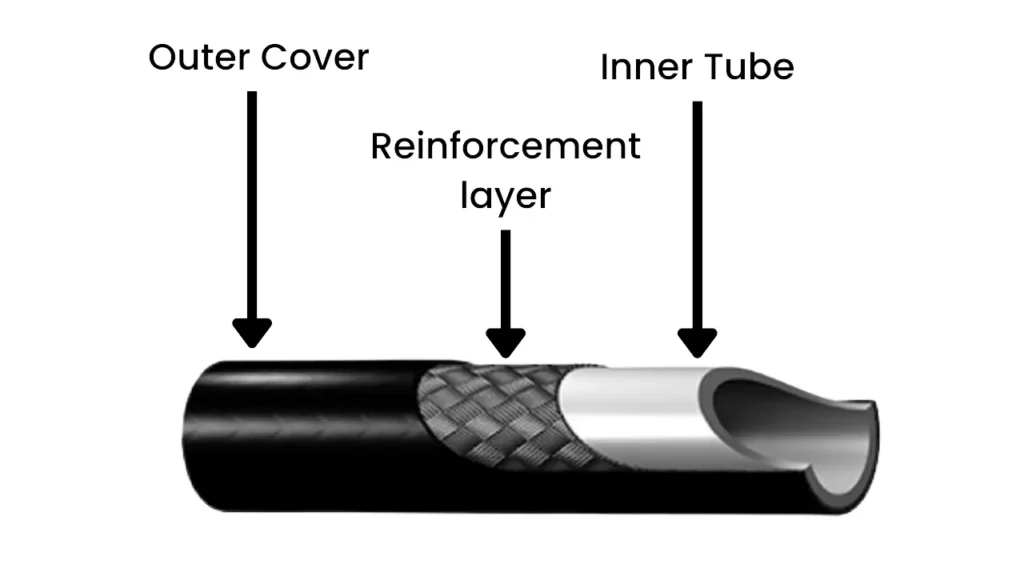

When considering the size of a hydraulic hose, two primary hydraulic hose dimensions are crucial:

1. Inner Diameter (ID)

- Fluid Flow Capacity: The inner diameter directly influences the volume of fluid that can pass through the hose per unit of time.

- Pressure Drop: A larger ID can reduce pressure drop, ensuring efficient fluid delivery to hydraulic components.

- Flow Velocity: The ID affects the velocity of the fluid, which can impact factors like erosion and turbulence.

2. Outer Diameter (OD)

- Fitting Compatibility: The outer diameter determines the size of fittings that can be used to connect the hose to other components in the hydraulic system.

- Mechanical Strength: A larger OD often indicates a stronger hose, capable of withstanding higher pressures and external forces.

- Bend Radius: The OD influences the minimum bend radius of the hose, which is important for routing the hose in confined spaces.

In addition to these two primary dimensions, other factors can also influence hose size selection:

- Pressure Rating: The maximum pressure the hose can withstand without failing.

- Temperature Range: The operating temperature range of the fluid.

- Fluid Compatibility: The type of fluid being used and its compatibility with the hose material.

- Hose Length: The required length of the hose.

- Bend Radius: The minimum radius the hose can be bent without damage.

- Environmental Factors: Exposure to UV light, ozone, chemicals, or abrasion.

By carefully considering these factors, you can select the appropriate hydraulic hose size to ensure optimal performance and longevity of your hydraulic system.

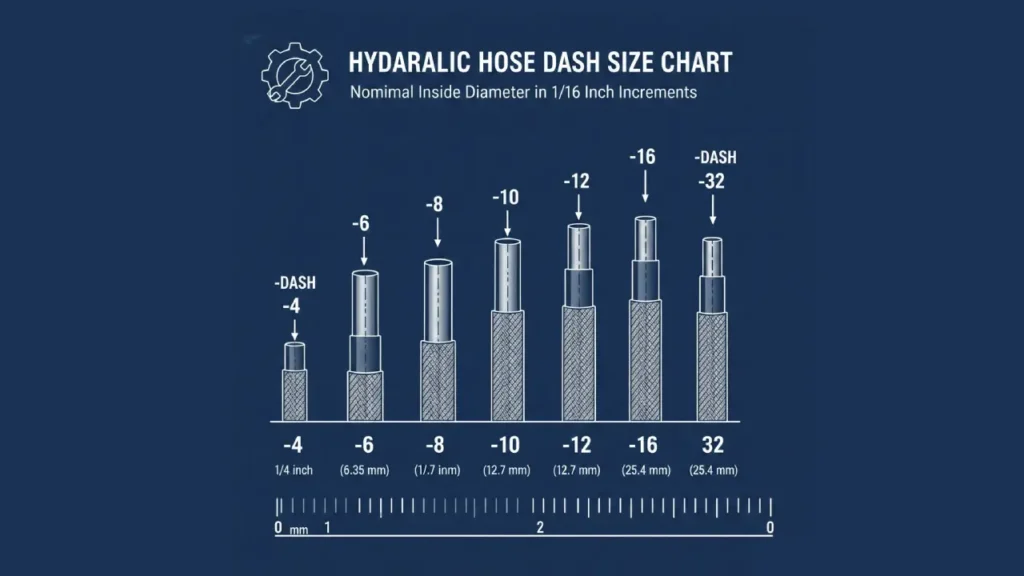

Hydraulic Hose Dash Size

Dash size is a common measurement system used to denote the diameter of hydraulic hoses, tubes, and fittings. It represents the inside diameter (ID) in increments of 1/16th of an inch.

For example:

- -6 hose: This indicates a hose with an inside diameter of 6/16th of an inch, or 3/8 inch.

- -10 fitting: This refers to a fitting with a 10/16th inch or 5/8 inch inside diameter.

Why Hydraulic Hose Dash Size Matters

The correct dash size is crucial for several reasons:

- Flow Rate: A larger dash size allows for greater fluid flow, improving system performance.

- Pressure Rating: The dash size influences the hose’s pressure rating, ensuring it can withstand the required operating pressures.

- Fitting Compatibility: The dash size determines the appropriate fittings that can be used to connect the hose to other components.

- Hose Life: Proper sizing helps prevent excessive stress and wear on the hose, extending its lifespan.

Factors to Consider When Selecting Dash Size

- Flow Rate: The required volume of fluid to be transported per unit of time.

- Pressure: The maximum pressure the system will experience.

- Temperature: The operating temperature range of the fluid.

- Fluid Compatibility: The type of fluid being used and its compatibility with the hose material.

- Bend Radius: The minimum radius the hose can be bent without damage.

- Environmental Factors: Exposure to UV light, ozone, chemicals, or abrasion.

To ensure accurate hose sizing, consult with a hydraulics expert or refer to manufacturer‘s guidelines.

By understanding dash sizes and the factors influencing hose selection, you can optimize your hydraulic system’s performance and reliability.

How to Determine Hydraulic Hose Size

Determining the correct hydraulic hose size is crucial for optimal system performance and safety. Here are the key factors to consider and steps to follow:

Key Factors:

The volume of fluid that needs to be transported per unit of time.

A higher flow rate requires a larger hose size.

The maximum pressure the hose must withstand. Higher pressure demands a hose with a thicker wall and higher pressure rating.

Temperature Range:

The operating temperature range of the fluid. Extreme temperatures can affect hose material and performance.

The type of fluid being used and its compatibility with the hose material. Incompatible fluids can damage the hose.

The minimum radius the hose can be bent without damage. Tight bends require more flexible hoses.

Environmental Factors:

Exposure to UV light, ozone, chemicals, or abrasion. These factors can accelerate hose degradation.

Steps to Determine Hydraulic Hose Size:

Selecting the right hose size ensures your machinery operates with peak efficiency and safety. We need to focus on the inner diameter to maintain proper flow velocity and avoid pressure drops. By following these specific measurement steps, we can guarantee that your equipment handles the required fluid volume without overheating.

Tools Needed

- Caliper or measuring tape

- Nomogram chart

- Manufacturer specification sheet

- Safety glasses and gloves

Step 1 Identify The Inner Diameter

We start by measuring the inside of the hose rather than the outside shell. You should use a precise caliper to get an exact reading of the opening where fluid flows. This internal dimension is critical because it dictates the velocity of the liquid as it moves through your entire system.

Standard industry practice uses dash sizes to represent these measurements in sixteenths of an inch. We convert your decimal or fraction reading into these specific units to match available parts. Accurate sizing prevents turbulence and excessive heat buildup, which helps extend the overall lifespan of your hydraulic components and seals.

Step 2 Consult A Nomogram Chart

We use a nomogram to find the relationship between flow rate and velocity. You simply draw a straight line between the known flow rate and the recommended velocity for your specific application. This visual tool shows exactly which inner diameter we need to select for the most efficient fluid transfer possible.

The chart helps us stay within the safe operating limits for suction or pressure lines. We look for the intersection point on the center scale to confirm our size choice is correct. Following these engineering standards ensures your system remains reliable and avoids the risk of premature hose failure during use.

How to Measure Hydraulic Hose Size

To accurately measure a hydraulic hose size, you’ll need to measure its inner diameter (ID).

Here’s how:

1. Locate the two ends of the hose you want to measure.

2. Use a ruler or tape measure to measure the distance across the inside of the hose from one inner edge to the other.

Important: Do not include the outer cover or sheath in your measurement.

3. Record the measurement in inches or millimeters.

Note: Hydraulic hose sizes are often expressed in “dash sizes,” which are increments of 1/16th of an inch. For example, a -6 hose has an inner diameter of 6/16th of an inch, or 3/8 inch.

Additional tips:

- If you’re unsure about the measurement, consult a hydraulic hose specialist or refer to the manufacturer‘s specifications.

- When replacing a hose, it’s important to use a hose with the same ID and pressure rating as the original hose.

- Always consider the hose’s length, bend radius, and environmental factors when selecting a replacement hose.

By following these steps, you can accurately measure your hydraulic hose size and ensure that you select the correct replacement hose.

Using a Nomogram to Determine Hydraulic Hose Size

A nomogram is a graphical tool that allows you to determine a value based on two other known values. In the case of hydraulic hose sizing, a nomogram can help you determine the appropriate hose size based on the desired flow rate and velocity.

How to Use a Nomogram:

Identify the Known Values:

- Flow Rate: The volume of fluid you need to transport per unit of time (e.g., gallons per minute, liters per minute).

- Velocity: The desired speed of the fluid flowing through the hose (e.g., feet per second, meters per second).

Locate the Scales:

Find the scales on the nomogram that correspond to flow rate and velocity.

Draw a Straight Line:

Use a straight edge to connect the values for flow rate and velocity on their respective scales.

Read the Hose Size:

The point where the straight line intersects the hose size scale indicates the appropriate hose size.

Important Considerations:

- Accuracy: Ensure you are reading the scales accurately.

- Fluid Compatibility: Choose a hose material compatible with the fluid being used.

- Pressure Rating: Select a hose with a pressure rating that exceeds the maximum system pressure.

- Temperature Range: Consider the temperature range the hose will be exposed to.

- Bend Radius: Ensure the hose can be routed without excessive bending.

Hydraulic Hose Size Selection

Hydraulic hose size, often expressed in “dash sizes,” refers to the inner diameter (ID) of the hose. A “-6” hose, for instance, has an ID of 6/16th of an inch, or 3/8 inch.

Key Factors for Hydraulic Hose Selection

When selecting a hydraulic hose, several factors must be considered:

Flow Rate:

- The volume of fluid that needs to be transported per unit of time.

- Higher flow rates require larger hose sizes to avoid excessive pressure drops and maintain efficient system performance.

Pressure Rating:

- The maximum pressure the hose must withstand.

- Higher pressure applications demand hoses with thicker walls and higher pressure ratings.

Temperature Range:

- The operating temperature range of the fluid.

- Extreme temperatures can affect hose material and performance.

Fluid Compatibility:

- The type of fluid being used and its compatibility with the hose material.

- Incompatible fluids can damage the hose.

Bend Radius:

- The minimum radius the hose can be bent without damage.

- Tight bends require more flexible hoses.

Environmental Factors:

- Exposure to UV light, ozone, chemicals, or abrasion.

- These factors can accelerate hose degradation.

Selecting the Right Size

Consult Manufacturer‘s Specifications:

- Refer to the hydraulic hose manufacturer’s catalog or website for specific recommendations.

- Consider factors like hose material, reinforcement, and fittings.

Use a Hydraulic Hose Nomograph:

A nomograph is a graphical tool that helps determine hose size based on flow rate, pressure, and other factors.

Consider Safety Factors:

- Always select a hose with a higher pressure rating than the maximum expected pressure.

- Factor in potential pressure surges or fluctuations.

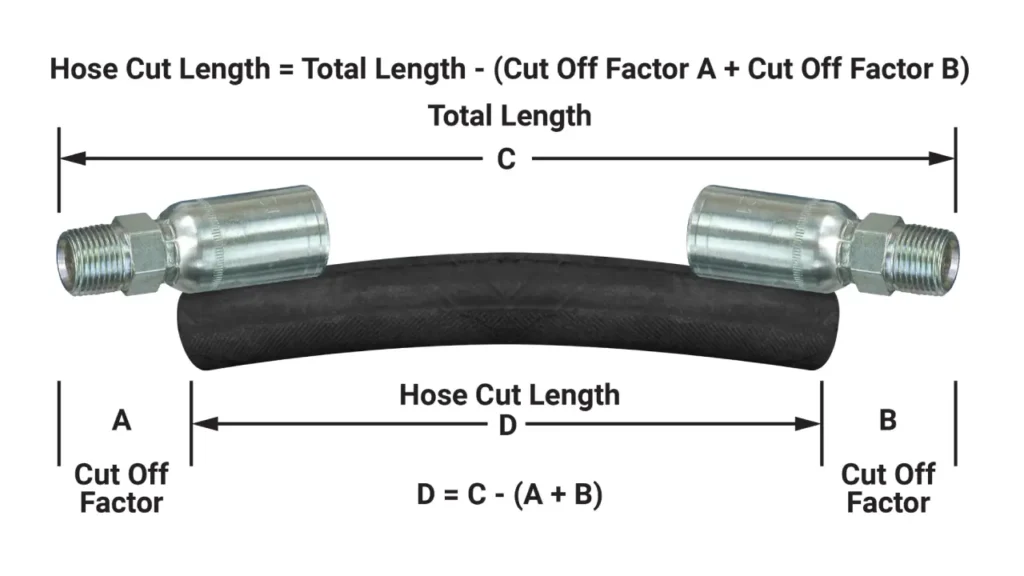

Verify Hose Length and Routing:

Determine the required hose length and plan the routing to avoid excessive bending or twisting.

Consult with a Hydraulic Expert:

If you’re unsure about the hose size or have complex system requirements, consult with a hydraulics engineer or specialist.

Measuring an Existing Hose

To measure an existing hose, you’ll need to measure its inner diameter (ID):

- Locate the two ends of the hose you want to measure.

- Use a ruler or tape measure to measure the distance across the inside of the hose from one inner edge to the other.

- Record the measurement in inches or millimeters.

By carefully considering these factors and following these steps, you can select the appropriate hydraulic hose size for your application, ensuring optimal performance and safety.

Do you have any specific questions about hydraulic hose sizing or selection?

Conclusion:

Choosing the right hydraulic hose is crucial for optimal system performance and safety. By understanding the factors influencing hose size selection, such as pressure rating, temperature range, and fluid compatibility, you can make informed decisions.

Remember to consult with hydraulic hose experts or refer to manufacturer guidelines for precise recommendations.

Don’t compromise on quality and safety. Invest in high-quality hydraulic hoses that meet your specific requirements.

Ready to upgrade your hydraulic system? Get your perfect hydraulic hose to meet your desired sizes now!

Contact us today for expert advice and fast delivery.