1 1/4 Hydraulic Hose

The 1 1/4 hydraulic hose is a robust and essential component in medium to heavy-duty hydraulic systems across numerous industries. Its significant internal diameter allows for substantial fluid flow rates, making it indispensable for applications requiring considerable power transmission and efficiency. From large construction machinery and agricultural equipment to industrial manufacturing and mining operations, this hose ensures the reliable and consistent delivery of hydraulic fluid. Understanding the capabilities and specifications of a 1 1/4 hydraulic hose is crucial for optimal system design, minimizing pressure drops, and maximizing the longevity and performance of critical hydraulic infrastructure.

Get Your Desired 1 1/4 Hydraulic Hose

The 1 1/4 hydraulic hose is a powerhouse in demanding hydraulic systems, vital for robust fluid transfer in heavy machinery and industrial applications. Its substantial diameter supports high flow rates, crucial for efficient power transmission and minimizing pressure loss.

All 1 1/4 Hydraulic Hoses

High-Pressure 1 1/4 Hydraulic Hose

When your hydraulic system demands immense power, the high-pressure 1 1/4 hydraulic hose steps up. These hoses are engineered with multiple layers of high-tensile steel wire spirals or braids, allowing them to withstand extremely high operating and burst pressures, often exceeding 5,000 PSI. They are indispensable in heavy-duty construction, mining, and large industrial machinery where components like large cylinders and motors require massive force. Their robust design ensures safety and reliability in the most strenuous and demanding hydraulic applications.

High-Temperature 1 1/4 Hydraulic Hose

Operating hydraulic systems in extreme heat demands a high-temperature 1 1/4 hydraulic hose. These hoses are constructed with advanced synthetic rubber compounds that can maintain their integrity and flexibility even when continuously exposed to elevated fluid and ambient temperatures. Unlike standard hoses that would rapidly degrade, harden, and crack under such conditions, high-temperature variants ensure reliable performance and extended service life in environments like engine compartments, steel mills, or foundries where heat is a constant challenge.

Suction and Return Line 1 1/4 Hydraulic Hose

While many 1 1/4 hydraulic hoses are designed for pressure, specific versions are optimized for suction and return lines. These hoses are constructed to resist collapse under vacuum on the suction side of a pump and handle lower pressures on the return side. They often have different reinforcement patterns to prevent kinking or deformation. Using the correct hose type for suction prevents cavitation and pump damage, while proper return line hoses ensure smooth fluid flow back to the reservoir, optimizing overall system efficiency.

1 1/4 Hydraulic Return Hose

1 1/4 hydraulic return hose is specifically engineered for the return line in hydraulic systems, carrying spent fluid back to the reservoir. Unlike pressure lines, return hoses are designed for lower pressure and often larger flow volumes, making this size ideal for efficient, low-resistance fluid transfer. Its construction prioritizes a smooth inner bore to minimize turbulence and heat buildup during fluid return, contributing significantly to overall system efficiency and the longevity of the hydraulic oil and components.

1/4 3000 PSI Hydraulic Hose

A 1/4 3000 PSI hydraulic hose is a robust and compact hose designed to withstand a continuous working pressure of up to 3000 pounds per square inch (PSI). This specific rating makes it suitable for a wide range of medium to high-pressure hydraulic applications where space is limited but significant force transmission is required. Its construction typically includes multiple layers of braided wire reinforcement to handle such pressures reliably, ensuring safety and performance in various industrial, mobile, and agricultural machinery.

Custom 1 1/4 Hydraulic Hose Wholesale

The 1 1/4 hydraulic hose is designed for superior flow rate capacity. Its larger bore minimizes resistance to fluid flow, which in turn reduces pressure drops across the hose line. This is critical for maintaining system efficiency, as a significant pressure drop can lead to reduced power at the actuator and increased energy consumption by the pump. For applications requiring high GPM (gallons per minute) or LPM (liters per minute), the 1 1/4 hydraulic hose ensures the hydraulic fluid move

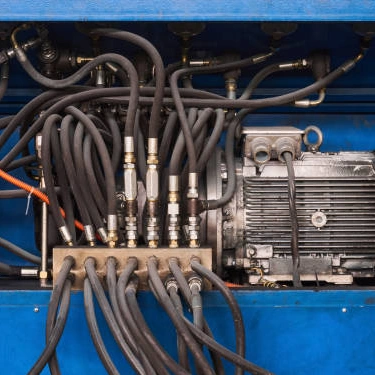

Material and Construction of 1 1/4 Hydraulic Hose

The durability and performance of a 1 1/4 hydraulic hose are directly attributed to its multi-layered construction and carefully selected materials. Typically, it comprises an inner tube compatible with various hydraulic fluids, robust reinforcement layers (commonly steel wire braids or spirals for strength), and an abrasion-resistant outer cover. This construction ensures the hose can withstand high internal pressures, resist external damage from harsh environments, and maintain its integrity against chemical degradation or extreme temperatures. The choice of materials dictates its flexibility, longevity, and overall suitability for demanding applications.

Pressure Handling of 1 1/4 Hydraulic Hose

While known for its flow, the 1 1/4 hydraulic hose is also engineered to handle considerable pressure. Depending on its reinforcement layers (e.g., multiple braids or spirals of high-tensile steel wire), these hoses can safely operate at various working pressures, often reaching several thousand PSI. The robust construction is essential to contain the powerful forces exerted by hydraulic fluid, preventing bursts and ensuring operator safety.

Key Applications for 1 1/4 Hydraulic Hose

The 1 1/4 hydraulic hose is a workhorse in industries that rely on heavy machinery and powerful hydraulic functions. You’ll find it extensively used in large construction equipment like excavators, bulldozers, and wheel loaders, where it handles the massive hydraulic power for digging, lifting, and moving materials. It’s also prevalent in agricultural machinery, logging equipment, material handling systems, and large industrial presses. Its ability to manage high flow and pressure makes it indispensable for applications requiring robust and continuous hydraulic power transmission.

What are the primary benefits of using a 1 1/4 hydraulic hose in a system?

The primary benefits of using a 1 1/4 hydraulic hose stem from its large internal diameter, which allows for significantly higher fluid flow rates. This capability is crucial for applications demanding substantial power and speed, as it minimizes pressure drop across the hose length. Reduced pressure drop leads to improved system efficiency, less heat generation, and optimal performance of hydraulic actuators like large cylinders and motors, ensuring your machinery operates at peak capacity.

Are there different types of reinforcement for 1 1/4 hydraulic hoses?

Yes, 1 1/4 hydraulic hoses come with various types of reinforcement, each designed to meet specific pressure and flexibility requirements. The most common types include braided steel wire reinforcement (single, double, or multiple braids) and spiral steel wire reinforcement (four or six spirals). Braided hoses often offer more flexibility, while spiral-wound hoses are typically used for extremely high-pressure applications.

The choice of reinforcement directly impacts the hose’s working pressure rating and its bend radius. For instance, a four-spiral 1 1/4 hydraulic hose will typically handle much higher pressures than a single-braid hose of the same size. Understanding these different reinforcement types is crucial for selecting a 1 1/4 hydraulic hose that provides the necessary strength and performance for your specific hydraulic system’s demands.

How does the pressure rating of a 1 1/4 hydraulic hose compare to smaller sizes?

The pressure rating of a 1 1/4 hydraulic hose can vary widely depending on its specific construction, particularly the type and number of reinforcement layers. While its larger diameter might intuitively suggest lower pressure ratings (due to a larger surface area for pressure to act upon), modern 1 1/4 hydraulic hoses are engineered with advanced materials and multiple layers of high-tensile steel wire (braids or spirals) to achieve very high working pressures, often comparable to or exceeding smaller hoses designed for similar applications.

It’s critical to always check the manufacturer’s specifications for the exact working pressure and burst pressure of any 1 1/4 hydraulic hose. For instance, a multi-spiral 1 1/4 hydraulic hose can easily handle pressures suitable for heavy machinery. When specifying, ensure the hose’s pressure capability comfortably exceeds the maximum expected operating pressure of your hydraulic system, including potential surges, to maintain a critical safety margin and prevent dangerous failures.

What industries commonly use 1 1/4 hydraulic hoses?

The 1 1/4 hydraulic hose is a workhorse in industries that rely on heavy machinery and robust hydraulic power. You’ll find it extensively used in the construction industry for equipment like large excavators, bulldozers, and wheel loaders, where it provides the immense power needed for digging, lifting, and moving heavy materials. Its capacity for high flow and pressure is essential for these demanding operations.

Beyond construction, the 1 1/4 hydraulic hose is also prevalent in agriculture for large tractors and implements, in mining operations for drilling and excavation equipment, and within industrial manufacturing for heavy presses, material handling systems, and other machinery requiring significant hydraulic force. Its reliability and high performance make it an indispensable component for maintaining productivity and operational safety in these demanding sectors.

What are the common signs of hydraulic hose failure?

Common signs of hydraulic hose failure include visible external damage like abrasion, cuts, cracks, or blistering on the outer cover. Other indicators are a leaking hose (even small drips), which suggests the hose’s integrity is compromised, or a hardened, stiff, or unusually soft/spongy hose, indicating material degradation due to heat or chemical exposure.

Internal damage, though less visible, can manifest as a loss of hydraulic system power or erratic operation due to blockages or internal tube collapse. Regularly inspecting your hydraulic hoses for these signs can prevent unexpected downtime, costly repairs, and potential safety hazards.

Quote 1 1/4 Hydraulic Hose Wholesale

Is your project held back by unsuitable hydraulic hoses? Don’t compromise on performance or struggle with ill-fitting components. We offer 3/16 hydraulic hose wholesale, custom-tailored to your exact specifications. Get precise lengths, ideal pressure ratings, and the perfect fittings for seamless integration, ensuring your systems operate with maximum efficiency and reliability, every time.