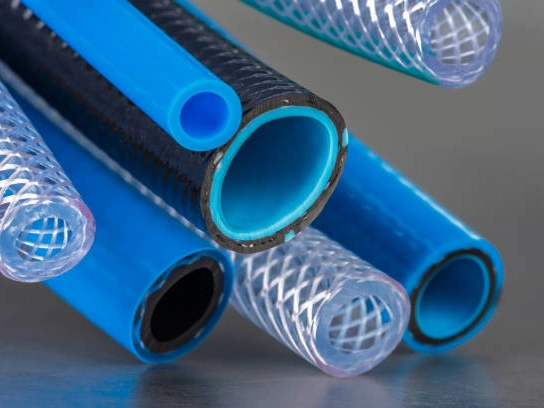

As a supplier of rubber hoses, we’ve seen countless fluid-handling solutions, but one product consistently stands out for its strength and reliability: braided hose. What’s so special about braided hoses? In this guide, we’ll share our expertise, detailing their construction, materials, and diverse uses, giving you an insider’s perspective on why they’re essential components for any serious project.

What is Braided Hose?

A braided hose is a type of reinforced flexible tubing designed to handle high pressures and challenging environments. Unlike standard rubber or plastic hoses, a braided hose features one or more layers of woven material. This reinforcement is the key to its strength and durability.

The “braid” acts like a protective cage, preventing the hose from expanding or bursting under pressure. It also offers excellent resistance to kinking and external abrasion, making it a robust solution for demanding applications.

What is Braided Hose Material?

The strength of a braided hose depends on its materials, which is why we offer a carefully selected range to meet our customers’ needs.

Stainless Steel Braided Hoses

This is our go-to for heavy-duty applications. The stainless steel braided hose is not only incredibly strong but also highly resistant to corrosion. We supply these for automotive brake lines, fuel systems, and hydraulic setups where maximum durability and a professional finish are required. The sleek look of stainless steel is a bonus for our performance-minded clients.

Aramid Fiber Braided Hoses

For our customers in the motorsports and aerospace industries, weight is a critical factor. That’s why we stock hoses with aramid fiber braids. These are exceptionally strong for their weight, providing outstanding burst pressure ratings. Their non-conductive properties are also a key safety feature for specific electrical and electronic applications.

Fiber and Textile Braided Hoses

Not every job needs the strength of steel. For lighter-duty applications like air lines or pneumatic systems, we supply hoses with polyester or nylon braids. They offer great flexibility and protection against kinking at a more accessible price point. We recommend these for general workshop or home use.

What is Braided Hose Used For?

Braided hoses are primarily used for applications that require a combination of high-pressure resistance, flexibility, and durability. Their core function is to safely transport fluids or gases in demanding environments where a standard rubber or plastic hose would fail.

In the automotive industry, they are essential for brake lines, fuel lines, and power steering systems. In industrial settings, they are the backbone of hydraulic and pneumatic equipment, from construction machinery to factory robots. For plumbing, braided supply lines connect faucets and toilets, offering a safe and flexible alternative to rigid pipes.

The added reinforcement makes them highly resistant to kinking and abrasion, ensuring a longer lifespan and greater reliability across a wide range of industries, including aerospace, manufacturing, and oil and gas.

What is the Difference Between Braided Hose and Standard Hose?

The core difference between a braided hose and a standard hose lies in their construction and, as a result, their performance. While a standard hose is typically a single or multi-layered tube made of rubber or a flexible polymer, a braided hose features an additional reinforcement layer—the braid—woven over the inner tube.

| Feature | Braided Hose | Standard Hose |

| Construction | Inner tube with a woven reinforcement layer (braid). | Single or multi-layered tube without reinforcement. |

| Pressure Rating | Designed for high-pressure systems. | Suitable only for low to medium pressure. |

| Durability | Highly resistant to kinking, abrasion, and bursting. | More susceptible to kinks and damage. |

| Flexibility | Generally more rigid due to the braid. | More flexible and pliable. |

| Typical Use | Automotive, hydraulics, industrial machinery. | Automotive, hydraulics, and industrial machi |

How to Choose the Right Braided Hose

As a supplier, we always ask our customers about their needs and consider various aspects to ensure they receive the right product.

- Fluid Compatibility: We ask our customers what fluid the hose will carry. The inner tube material must be compatible to prevent chemical degradation.

- Operating Pressure: We help customers determine the maximum system pressure so we can provide a hose with a safe working pressure rating.

- Temperature Range: We make sure the selected hose can handle the full range of temperatures it will be exposed to.

- Application Environment: We recommend outer covers that will protect the hose from external factors like abrasion, UV light, or chemicals.

- Size & Length: We help our clients choose the correct inner diameter for their required flow rate and ensure the length is appropriate for their setup.

By focusing on these key factors, we ensure our customers receive a braided hose that performs safely and reliably for years to come. We believe a small investment in a quality hose prevents major headaches and costly failures down the line.

Conclusion

Braided hose is more than just a product; it’s a symbol of quality and safety. Its innovative layered design solves complex fluid transfer problems, making it a reliable solution for high-pressure, high-stress environments. From our hands to yours, we firmly believe that providing high-quality braided hose is a key component of our commitment to customer success and safety.