The rubber hose manufacturing process is a fascinating blend of science, engineering, and precision. From selecting raw materials to applying advanced reinforcement techniques, every step is designed to produce durable, flexible, and reliable hoses. Understanding this process highlights the craftsmanship behind essential industrial and commercial equipment.

Modern rubber hoses must withstand pressure, abrasion, and environmental challenges while maintaining consistent performance. The manufacturing process involves extrusion, layering, curing, and rigorous quality control to meet strict industry standards. By exploring how rubber hoses are manufactured, businesses can better appreciate their value and ensure they select products that meet specific operational requirements.

Rubber Hose Materials

Rubber hoses are made from a variety of materials, each tailored to specific applications, pressure levels, and environmental conditions. Selecting the right material ensures durability, flexibility, and resistance to chemicals or extreme temperatures. Understanding the key materials can help in making informed choices for industrial, automotive, and household uses.

- Natural Rubber (NR): Natural rubber provides excellent elasticity, tensile strength, and abrasion resistance. It is ideal for air, water, and low-pressure fluid transfer. Its flexibility allows easy bending and handling, making it suitable for general-purpose hoses in moderate temperature conditions, though it is less resistant to oils and chemicals.

- Synthetic Rubber (SBR, NBR, EPDM): Synthetic rubbers are engineered for specific resistance properties. SBR offers abrasion resistance; NBR withstands oils and fuels; EPDM excels in heat, ozone, and weather resistance. Each type is chosen based on the hose’s operational environment, ensuring long-term performance under varying industrial or automotive conditions.

- PVC (Polyvinyl Chloride): PVC hoses are lightweight, cost-effective, and resistant to abrasion, corrosion, and many chemicals. They are suitable for water and low-pressure fluid applications. While less flexible than rubber, PVC hoses are easier to handle, store, and maintain, making them popular in domestic, agricultural, and light industrial settings.

- Silicone Rubber: Silicone rubber hoses are highly resistant to extreme temperatures, both hot and cold, as well as UV and ozone exposure. They are non-reactive, making them suitable for food, medical, and pharmaceutical industries. Despite higher cost, their long life and reliability in harsh conditions justify the investment.

- Neoprene Rubber (CR): Neoprene rubber offers moderate chemical resistance, flexibility, and durability. It performs well in air, water, and mild chemical applications. Its resistance to oil, ozone, and weathering makes it versatile for industrial hoses and pneumatic systems, bridging the gap between general-purpose and specialized high-performance hoses.

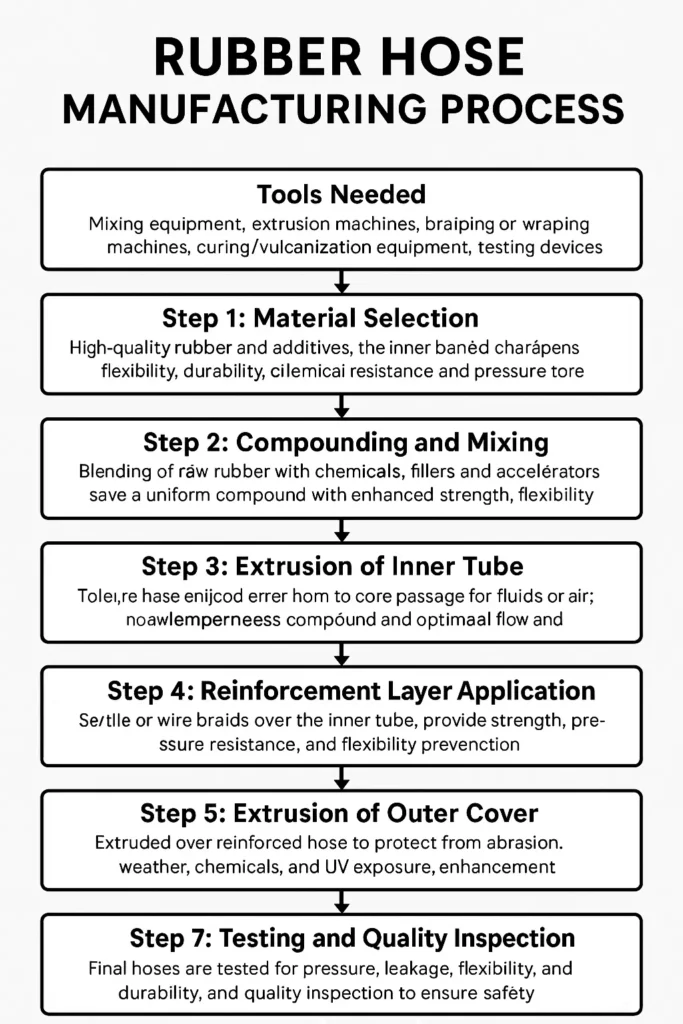

Rubber Hose Manufacturing Process

Manufacturing rubber hoses is a precise process combining engineering, material science, and quality control. Each step ensures the hoses are durable, flexible, and capable of withstanding pressure. Understanding the process helps produce reliable hoses for industrial, automotive, and commercial applications.

Before starting the rubber hose manufacturing process, it is essential to prepare the right tools and equipment. Proper tools ensure precision, efficiency, and safety during each stage of production. Using suitable instruments reduces errors, maintains quality standards, and streamlines the workflow for consistent hose manufacturing.

Tools Needed

- Mixing equipment: Used for blending rubber compounds and additives evenly for uniform material properties.

- Extrusion machines: Shape the inner tube, reinforcement, and outer cover accurately according to specifications.

- Braiding or wrapping machines: Apply reinforcement layers consistently for strength and pressure resistance.

- Curing/vulcanization equipment: Ensure proper heat and pressure to crosslink rubber molecules efficiently.

- Testing devices: Check pressure, leaks, flexibility, and durability to meet industry quality standards.

Proper preparation and use of these tools allow us to maintain high manufacturing standards. Each tool plays a critical role in producing hoses that are durable, flexible, and capable of performing reliably under industrial and commercial conditions.

By having all tools ready before Step 1, we can streamline production, reduce waste, and prevent delays. Organized workflow and precise equipment handling ensure that every hose meets performance and safety requirements consistently.

Step 1: Material Selection

Selecting high-quality rubber and additives is the first step in hose manufacturing. The material choice affects flexibility, durability, chemical resistance, and pressure tolerance, ensuring the final product meets specific performance requirements for diverse applications.

We carefully analyze rubber properties and mix with reinforcing agents, fillers, and stabilizers. This ensures consistent elasticity, resistance to wear, and performance under temperature variations. Proper selection forms the foundation for hoses that can handle rigorous industrial and commercial use.

Step 2: Compounding and Mixing

Rubber compounding involves blending raw rubber with chemicals, fillers, and accelerators. This creates a uniform material with enhanced strength, flexibility, and resistance to heat, pressure, and abrasion.

We use precise mixing techniques to ensure the compound is homogeneous. Proper compounding guarantees consistent quality, reduces defects, and optimizes hose performance for both short-term functionality and long-term durability.

Step 3: Extrusion of Inner Tube

The inner tube of the hose is extruded to form the core passage for fluids or air. This step determines hose diameter, wall thickness, and smoothness for optimal flow and performance.

We monitor extrusion speed, temperature, and die design to achieve uniform tube dimensions. This precision ensures the hose can handle specified pressure ratings and maintain efficient flow without leaks or weak points.

Step 4: Reinforcement Layer Application

Reinforcement layers, such as textile or wire braids, are applied over the inner tube. These layers provide strength, pressure resistance, and flexibility to the hose, preventing collapse or bursting under high pressure.

We carefully wrap or braid reinforcement material to achieve consistent coverage and bonding. Proper reinforcement enhances durability, reduces wear, and ensures the hose can handle demanding industrial or hydraulic applications.

Step 5: Extrusion of Outer Cover

The outer rubber cover is extruded over the reinforced hose to protect it from abrasion, weather, chemicals, and UV exposure. This layer also enhances flexibility and longevity of the hose.

We select materials suitable for environmental and operational conditions, then apply the cover uniformly. A well-formed outer layer ensures mechanical protection, extends service life, and maintains the hose’s aesthetic and functional integrity.

Step 6: Curing and Vulcanization

The hose undergoes vulcanization to crosslink rubber molecules, improving elasticity, strength, and heat resistance. Proper curing ensures the hose maintains shape, flexibility, and performance under pressure and temperature variations.

We control time, temperature, and pressure during curing to achieve optimal crosslinking. Consistent vulcanization prevents weak spots, enhances durability, and ensures the hose performs reliably in industrial, automotive, and commercial applications.

Step 7: Testing and Quality Inspection

Final hoses are tested for pressure, leakage, flexibility, and durability. Quality inspection ensures that each hose meets industry standards and performs safely under specified conditions.

We conduct rigorous testing, including burst pressure, dimensional checks, and visual inspection. This step guarantees only hoses that meet high-performance standards are shipped, ensuring reliability, safety, and long-lasting functionality for end users.

Rubber Hose Applications

Rubber hoses are versatile tools used across various industries for fluid and air transfer. Their durability, flexibility, and resistance to pressure make them essential in industrial, automotive, and commercial settings. Understanding the key applications helps businesses select the right hose for specific operational needs.

Industrial Applications

- Fluid transfer: Moving water, oil, chemicals, and other liquids efficiently.

- Compressed air systems: Delivering air to tools and machinery.

- Hydraulic operations: Ensuring safe and reliable fluid power transmission.

- Manufacturing processes: Handling materials in production lines.

We provide rubber hoses that withstand high pressure and harsh conditions, ensuring smooth operations in factories and production facilities. These hoses are engineered for reliability, maintaining consistent performance under demanding industrial workloads while reducing downtime and maintenance costs.

Automotive Applications

- Engine cooling: Circulating coolant to maintain optimal temperatures.

- Fuel delivery: Safely transporting gasoline or diesel.

- Air conditioning: Supporting HVAC systems in vehicles.

- Brake systems: Ensuring proper hydraulic brake function.

Our rubber hoses are built to endure heat, vibration, and chemical exposure common in automotive environments. By using high-quality hoses, we help maintain vehicle performance, reduce leaks, and provide long-lasting service for engines, braking, and other critical systems.

Commercial Applications

- Gardening and irrigation: Transporting water efficiently for plants and landscaping.

- Food and beverage processing: Moving liquids safely in compliance with hygiene standards.

- Construction: Supplying air or water to tools and equipment.

- Cleaning and maintenance: High-pressure hoses for sanitation or washing purposes.

We offer rubber hoses designed for safety, flexibility, and durability in commercial settings. By selecting hoses suited for specific tasks, we ensure reliable performance, minimize downtime, and improve productivity in everyday operations across multiple commercial applications.

Conclusion

In conclusion, understanding the rubber hose manufacturing process reveals the complexity and precision required to produce high-performance hoses. Every step, from material selection to quality testing, ensures durability, flexibility, and reliability. Choosing well-manufactured hoses helps maintain system efficiency and safety in demanding applications. Get wholesale rubber hoses from our Gushan Rubber.

By following these advanced manufacturing techniques, rubber hoses can meet diverse industrial requirements, resist wear, and perform consistently under pressure. Investing in high-quality hoses reduces downtime, maintenance costs, and operational risks. Our Gushan Rubber hoses are crafted with expertise to ensure dependable performance for every application.

For businesses seeking reliable and cost-effective solutions, sourcing from Gushan Rubber guarantees premium quality hoses in bulk. We provide hoses tailored to specific requirements, ensuring optimal performance and longevity. Partnering with us ensures you receive durable, high-performance rubber hoses to meet all industrial and commercial needs efficiently.