Hydraulic Hose Wrap

Is abrasion and impact damaging your hydraulic hoses? Combat premature wear and potential leaks with our robust hydraulic hose wraps. Safeguard your operations, extend hose lifespan, and prevent costly equipment failures. Invest in lasting protection and keep your systems running smoothly.

Get Your Desired Hydraulic Hose Wrap

Tired of hydraulic hose damage halting your work? Fend off abrasion, cuts, and crushing with our premium hydraulic hose wraps. Keep your machinery running reliably, avoid expensive downtime, and extend the life of your crucial components. Choose the perfect wrap to ensure your operations flow smoothly.

All Hydraulic Hose Wraps

hydraulic hose spiral wrap

Are your hydraulic hoses vulnerable to abrasion and impact? Prevent costly failures and messy leaks with our robust spiral hydraulic hose wrap. This easy-to-install solution extends hose life, reduces maintenance, and keeps your machinery operating safely. Protect your investment and ensure continuous productivity with our premium wraps.

heavy duty hydraulic hose spiral wrap

Worried about your heavy-duty hydraulic hoses failing prematurely? Harsh environments and constant abrasion can quickly degrade even the toughest hoses, leading to expensive downtime. Our robust heavy-duty hydraulic hose spiral wraps provide unmatched protection against wear, impact, and crushing. Safeguard your critical equipment, extend hose life significantly, and ensure uninterrupted, high-performance operation.

hydraulic hose protective wrap

Is your hydraulic hose vulnerable to damage? Don’t let abrasion and impacts lead to costly leaks and downtime. We offer premium hydraulic hose protector wraps designed for superior durability. Shield your investment, prevent premature hose failure, and ensure uninterrupted operations. Get the ultimate protection for your hydraulic systems today.

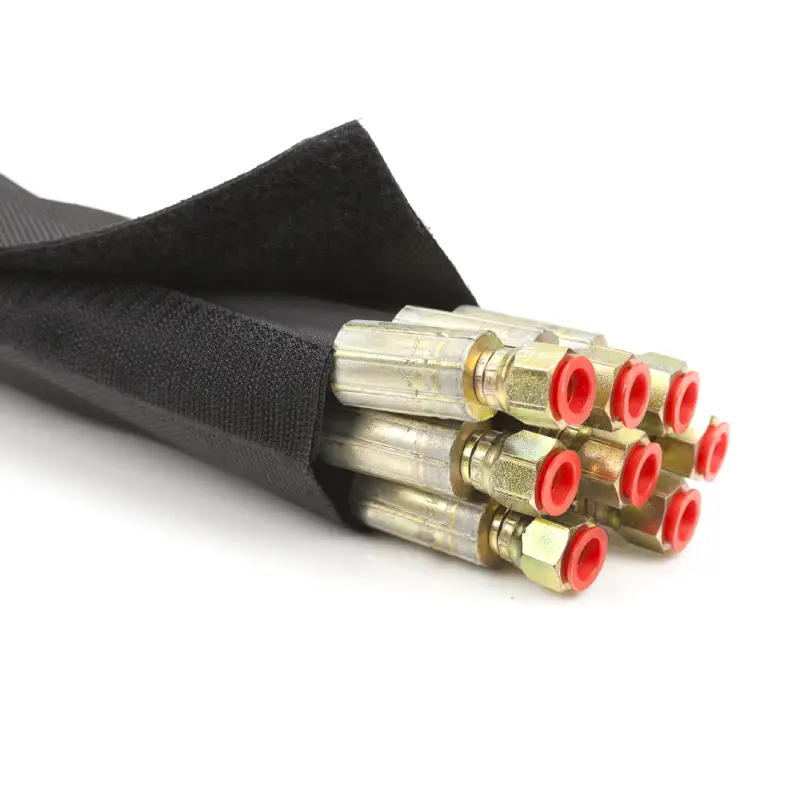

hydraulic hose wrap velcro

Struggling with complex hose protection installations? Frustrated by damaged hydraulic lines causing delays? Our Velcro hydraulic hose wraps offer a fast, secure solution. Easily apply and remove for quick inspections and maintenance, protecting your hoses from abrasion and cuts. Keep your equipment running efficiently with minimal fuss.

colored hydraulic hose wrap

Tired of messy, unidentifiable hydraulic lines? Frustrated by slow troubleshooting? Our colored hydraulic hose wraps not only provide superior abrasion and impact protection, but also enable instant visual identification. Streamline maintenance, enhance safety, and clearly differentiate circuits, making your operations more organized and efficient.

hydraulic hose wrap spiral tubing

Are your hydraulic hoses vulnerable to abrasion and crushing, leading to frequent replacements? Our hydraulic hose wrap spiral tubing provides robust, continuous protection, extending hose life significantly. Easily installed, it shields against harsh environments and impacts. Safeguard your equipment and minimize costly downtime with our durable solution, available now.

Custom Hydraulic Hose Wrap Wholesale

Tailored Sizing and Lengths

We offer hydraulic hose wraps in a wide range of custom diameters and lengths. Whether you need to protect a single, large-diameter hose or numerous smaller lines, we can precisely match your specifications. This ensures complete coverage and optimal protection for all your hydraulic systems.

Branding and Labeling

For our wholesale partners, we offer custom branding and labeling services. We can incorporate your company logo directly onto the hose wraps, enhancing brand visibility and professionalism. This is ideal for OEMs or distributors looking to offer a branded protection solution.

Material and Color Customization

We provide options for various materials, including heavy-duty nylon, polypropylene, and specialized fire-retardant fabrics. You can also choose from a spectrum of colors, allowing for brand consistency or color-coding for different hydraulic circuits within your machinery.

Bulk Order Flexibility and Support

We specialize in fulfilling large-volume custom orders, providing competitive wholesale pricing. Our team works closely with you to manage logistics, ensuring timely delivery to your specified location in Qingdao or beyond. We’re here to support your project from concept to completion.

what is hydraulic hose wrap?

Hydraulic hose wrap is a protective covering applied to hydraulic hoses. It shields them from external damage like abrasion, cuts, impacts, and environmental factors such as UV rays and chemicals.

This protective layer extends the lifespan of the hoses and prevents costly leaks and system downtime.

what is hydraulic hose wrap made of?

Hydraulic hose wraps are manufactured from various durable materials, selected to provide specific levels of protection against a range of environmental and operational hazards.

The choice of material depends heavily on the application’s demands, including exposure to abrasion, impacts, chemicals, UV radiation, and temperature extremes. These materials are engineered to be tough yet flexible, ensuring they don’t compromise the hose’s functionality while offering superior defense.

Common materials used for hydraulic hose wraps include:

High-Density Polyethylene (HDPE): A very common choice for spiral wraps due to its excellent abrasion resistance, impact protection, and flexibility. It’s often used for general-purpose protection in demanding environments like construction and agriculture.

Nylon: Known for its high strength, wear resistance, and ability to withstand high temperatures. Ballistic nylon, a particularly strong weave, is often used for heavy-duty sleeves that offer superior abrasion and cut resistance.

Polyester: A durable synthetic fabric offering good abrasion and chemical resistance. It’s often used for lighter-weight sleeves and can be combined with other materials for enhanced properties.

Polypropylene (PP): Another plastic widely used for spiral wraps, offering good resistance to chemicals, abrasion, and a broad temperature range.

Silicone Rubber: Primarily used for fire-resistant sleeves due to its high-temperature performance and flame retardant properties, often found in applications where fire safety is paramount.

Vinyl: A high-strength thermoplastic that offers good water and chemical resistance, suitable for applications requiring protection against moisture and various chemicals.

what is hydraulic hose wrap used for?

Hydraulic hose wrap is primarily used to protect hydraulic hoses from premature wear and damage, thereby extending their lifespan and ensuring the reliability and safety of hydraulic systems.

Hydraulic hoses in industrial and mobile equipment are frequently exposed to harsh environments, constant movement, and potential contact with abrasive surfaces, sharp edges, or other components. The wrap acts as a sacrificial layer, absorbing impacts, resisting abrasion, and providing a barrier against various environmental factors.

Here are its main uses of hydraulic hose wrapes:

Abrasion Resistance: It prevents the outer cover of the hose from wearing down due to rubbing against other hoses, machinery parts, or rough surfaces.

Impact Protection: The wrap provides a cushioning layer that protects hoses from impacts caused by falling debris or accidental contact with equipment.

Environmental Shielding: It offers protection against UV radiation, chemicals, oil, dirt, and extreme temperatures, all of which can degrade hose material over time.

Bundling and Organization: Hose wraps can be used to bundle multiple hydraulic lines together, creating a neater appearance, preventing tangling, and making maintenance easier.

Safety Enhancement: By protecting hoses from damage that could lead to leaks or bursts, hose wraps contribute to a safer working environment, reducing the risk of injuries from high-pressure fluid injection or slips caused by spilled fluid.

Cost Reduction: By extending hose life and preventing unplanned downtime due to hose failure, hydraulic hose wraps significantly reduce maintenance and replacement costs.

how to use hydraulic hose wraps?

Properly using hydraulic hose wraps is crucial for maximizing their protective benefits and extending the life of your hydraulic hoses. The application method varies slightly depending on the type of wrap.

Step 1: Prepare the Hose and Wrap

Before applying the wrap, ensure the hydraulic hose surface is clean and free of oil, dirt, or debris. This helps prevent contaminants from being trapped underneath the wrap, which could potentially cause damage over time. Uncoil the hydraulic hose wrap and measure the desired length, allowing for some overlap if necessary.

For spiral wraps, ensure the initial end is securely fastened. For sleeve-style wraps, you might need to disconnect hose ends for easier sliding. Plan the wrap’s path, considering any bends or branching points in the hose. Proper preparation ensures a snug and effective fit for optimal protection against abrasion and impact.

Step 2: Apply the Wrap

For spiral wraps, begin at one end of the hose and start winding the wrap tightly around the hose in a spiral motion, overlapping each turn by a consistent amount (typically 20-30% for good coverage). Maintain tension to ensure the wrap stays snug and doesn’t slip. Continue winding along the entire length of the hose that requires protection.

For sleeve-style wraps, slide the sleeve over the hose, ensuring it covers the desired area. If it’s a Velcro wrap, align the edges and press them firmly together along the entire length to secure it. Ensure there are no gaps that could expose the hose to damage.

Step 3: Secure the Ends (if applicable)

For spiral wraps, once you reach the end of the desired protective length, secure the final turn of the wrap to prevent it from unwinding. This can often be done by tightly wrapping the end or, in some cases, using a cable tie or specialized fastener if the wrap material allows.

For pre-cut sleeves or those with integrated fastening mechanisms like Velcro, ensure all fastening points are properly engaged. Double-check that the wrap is securely in place, covers all vulnerable areas, and does not interfere with the hose’s flexibility or connection points.

why choose our hydraulic hose wraps?

Premium Durability: Our wraps are crafted from top-grade materials like robust HDPE and high-strength nylon, offering unparalleled resistance to wear, cuts, and punctures in demanding industrial environments.

Enhanced Safety: By protecting hoses from damage and potential bursts, our wraps significantly reduce the risk of fluid injection injuries and slips, contributing to a safer work environment for your team.

Extended Hose Lifespan: Proactive protection against external damage means your hydraulic hoses last longer, reducing the frequency of costly replacements and associated labor.

Reduced Downtime: Preventing hose failures translates directly to less unscheduled maintenance and maximized operational uptime for your machinery and equipment.

Versatile Solutions: We offer a wide variety of wraps, including spiral wraps, protective sleeves, and Velcro options, available in custom sizes and materials to perfectly match your specific application needs.

Cost-Effectiveness: While an initial investment, the long-term savings from reduced hose replacements, fewer repairs, and consistent operation far outweigh the cost, offering a strong return on investment.

Expert Support: Our team provides knowledgeable assistance, helping you select the ideal hose wrap solution for your unique challenges and ensuring optimal performance.

Quote Hydraulic Hose Wrap Wholesale

Are exposed hydraulic hoses a constant source of worry, leading to costly repairs and downtime? Our wholesale hydraulic hose wraps provide superior protection against abrasion, impacts, and environmental damage. Secure your operations, extend hose life, and maintain peak performance. Get a quote today and shield your equipment effectively.