Leading Hydraulic Hose Manufacturer to Provide You Hydraulic Solutions

As a leading hydraulic hose manufacturer, we specialize in producing high-performance hoses designed to withstand demanding applications. Our commitment to quality and innovation ensures superior strength, flexibility, and durability. We offer a wide range of sizes and materials, including rubber and thermoplastic options, to meet the unique requirements of various industries.

Featured Hydraulic Hoses

Our advanced hydraulic hose manufacturing capabilities allow us to produce a wide range of custom made hydraulic hoses tailored to your specific requirements.

-

SAE 100R3

Read more -

SAE 100R9

Read more -

SAE 100R8

Read more -

SAE 100R7

Read more -

SAE 100R5

Read more -

SAE 100R4

Read more -

Wrapped Oil / Fuel Hose

Read more -

Wrapped Air / Water Hose

Read more -

Twin Line Hose

Read more -

Suction & Discharge Water Hose

Read more -

Suction & Discharge Oil Hose

Read more -

Smooth Oil / Fuel Hose

Read more -

Smooth Air / Water Hose

Read more -

Sandblast Hose

Read more -

Oxygen Hose

Read more -

Mutil-purpose Hose

Read more -

LPG Hose

Read more -

Acetylene Hose

Read more

Wide Range of Sizes

We offer a wide range of hydraulic hoses, varied in sizes (lengths, diameters) to meet the diverse needs of your specific applications. Whether you require high-pressure hydraulic hoses for heavy-duty equipment or specialized hoses for unique operating environments, we have the perfect solution. Our extensive selection ensures you can find the ideal hydraulic hose to optimize your system’s performance and efficiency.

Excellent Pressure Resistance

Our hydraulic hoses are built to withstand extreme pressures without compromising performance. We utilize advanced manufacturing techniques and high-strength materials to create hoses that can handle the most demanding hydraulic systems. Experience the confidence of knowing your hydraulic system is protected from leaks and failures, ensuring optimal performance and minimizing downtime.

Safety and Reliability

Safety is paramount. Our hydraulic hoses are meticulously tested and inspected to ensure they meet or exceed industry safety standards. We prioritize reliability and minimize the risk of hose failures, protecting your valuable equipment and personnel from potential hazards. Choose our hoses for a safer and more reliable hydraulic system.

Hydraulic Hose Manufacturing Process

By following these steps and adhering to strict quality control standards, our hydraulic hose manufacturer can produce high-quality hydraulic hoses that meet the demanding requirements of various industries.

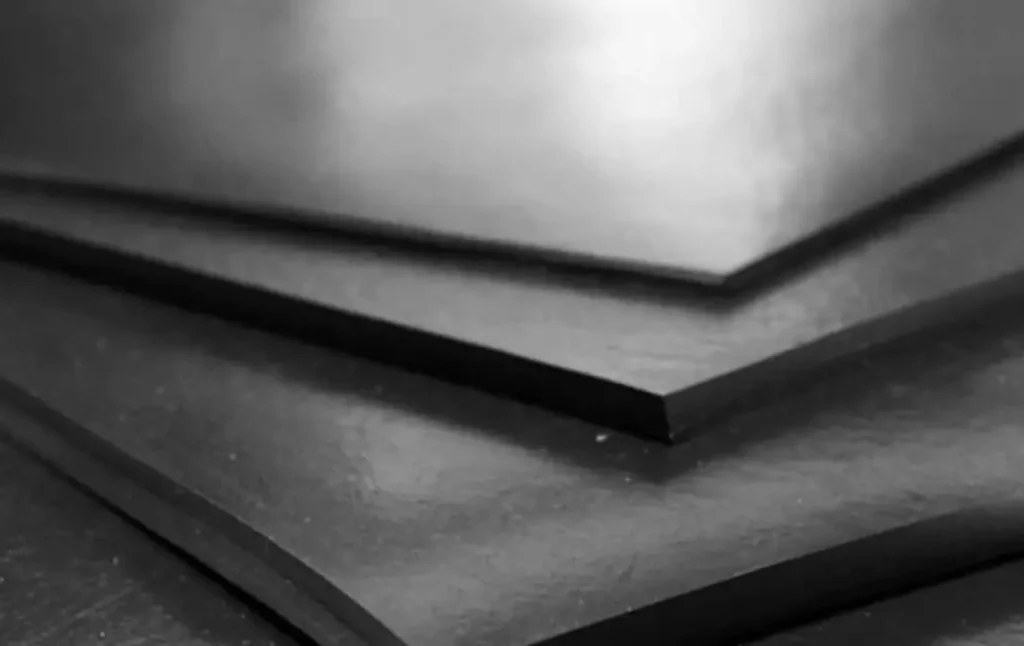

1. Rubber Material Mixing

We meticulously blend high-quality rubber compounds, precisely controlling factors like temperature and mixing time to achieve optimal consistency and performance for our hydraulic hoses.

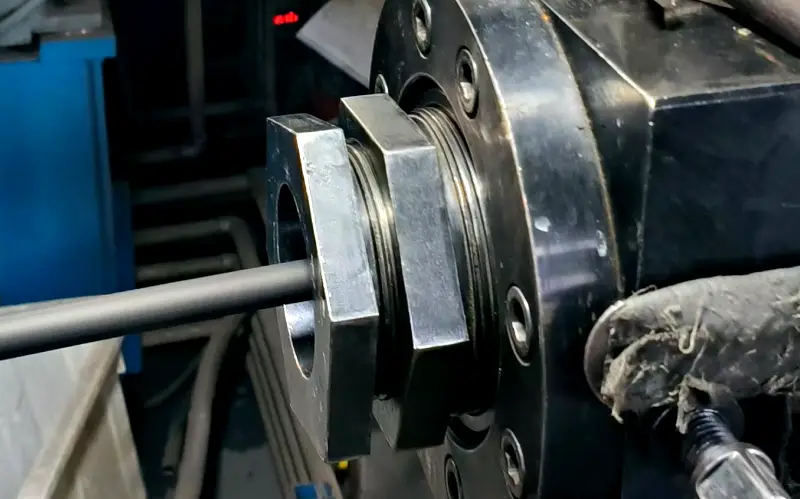

2. Hydraulic Hose Extruding Process

We extrude rubber compounds through dies to create precise inner tubes and outer covers for hydraulic hoses. Our advanced extrusion process ensures consistent quality and dimensional accuracy.

3. Hydraulic Hose Braiding Process

We braid steel wire or textile fibers around the inner tube to reinforce and resist pressure. This braiding process enhances the hose’s durability and flexibility.

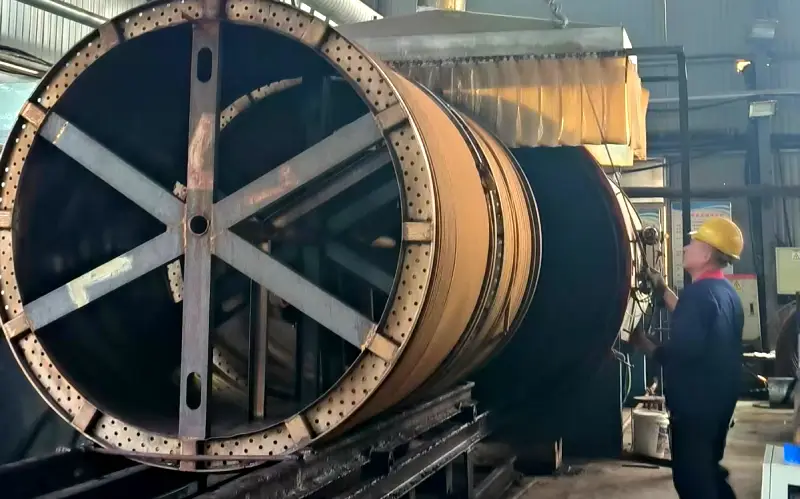

4. Hydraulic Hose Vulcanizing Process

We vulcanize hydraulic hoses by subjecting them to high temperature and pressure. This process cross-links the rubber molecules, enhancing their strength, durability, and resistance to oil and heat.

5. Hydraulic Hose Hydrostatic Testing

We conduct rigorous hydrostatic testing on our hydraulic hoses. This involves subjecting the hoses to pressures significantly exceeding their rated working pressure to ensure they can withstand extreme conditions and maintain their integrity.

6. Hydraulic Hose Impulse Test

We conduct rigorous quality tests on our hydraulic hoses, including pressure testing, bend radius testing, and impulse testing to ensure durability, flexibility, and resistance to extreme conditions.

7. Hydraulic Hose Packing Process

We conduct hydraulic hose packing tests with fabric wrap to assess the hose’s ability to withstand external pressures, protect against abrasion, and maintain its integrity in harsh environments.

Hydraulic hoses are versatile components that power a wide range of machinery and equipment across various industries. Here are six key applications where hydraulic hoses play a crucial role:

Construction Machinery

Hydraulic hoses are widely used in construction machinery such as excavators and bulldozers. They control hydraulic cylinders, enabling actions like digging, shoveling, and lifting. Their high-pressure and abrasion resistance ensure reliable operation in harsh conditions.

Coal Mining

Coal mining equipment demands high abrasion and corrosion resistance from hydraulic hoses. These hoses control mining machines like shearers and roadheaders, maintaining stable performance in high-temperature, high-humidity, and dusty environments.

Agricultural Machinery

Hydraulic systems in agricultural machinery, such as tractors and harvesters, extensively utilize hydraulic hoses. They control hydraulic cylinders and motors for lifting, turning, and other operations. The hoses' weather resistance and oil resistance make them suitable for outdoor work.

Automotive Industry

The automotive industry utilizes hydraulic hoses in various systems, including power steering and braking systems. These hoses must be flexible, durable, and capable of handling high pressure. They ensure smooth and efficient operation of vehicles.

Aerospace Applications

Hydraulic hoses in aerospace applications must withstand extreme conditions. They control various systems in aircraft, requiring high-temperature, low-temperature, and corrosion resistance. These hoses ensure the reliable operation of critical systems.

Offshore Applications

Hydraulic hoses in offshore applications power various equipment, including cranes, winches, and steering systems. They must withstand harsh marine environments, including saltwater corrosion, extreme temperatures, and high pressure.

The Real Feedback From Our Client

Hydraulic Hose FAQs

what is Hydraulic Hose?

A hydraulic hose is a flexible tube specifically designed to convey high-pressure fluids, typically hydraulic oil or water, within a hydraulic system.

what is Hydraulic Hose made of?

Hydraulic hoses are typically made of several layers of different materials:

Inner Tube:

- Usually made of synthetic rubber (like nitrile rubber or polyurethane) or thermoplastic materials.

- This layer is in direct contact with the hydraulic fluid.

Reinforcement Layer(s):

- Provides the hose with its strength and ability to withstand high pressures.

- Common materials include:

- Steel wire: Offers excellent strength and pressure resistance.

- Textile braids: Used in lower-pressure applications.

Outer Cover:

- Protects the inner layers from abrasion, chemicals, and environmental factors.

- Typically made of synthetic rubber (like neoprene or nitrile rubber).

The specific materials used in a hydraulic hose will depend on the application, the type of fluid being conveyed, the operating pressure, and other factors.

How many types of hydraulic hose do you have?

Here we can all hydraulic hoses that are trending on the hydraulic hose market, and this is the hydraulic hose models that can offer in the following:

- SAE 100R1AT/ DIN EN853 1SN

- SAE 100R2AT / DIN EN853 2SN

- SAE 100R 1A / DIN EN853 1ST

- SAE 100R 2A / DIN EN853 2ST

- DIN EN857 1SC

- DIN EN857 2SC

- DIN EN856 4SP

- DIN EN856 4SH

- SAE 100R4

- SAE 100R5

- SAE 100 R6

- SAE 100R7

- SAE 100R8

- SAE 100R12

- SAE 100R13

- SAE 100 R14

- SAE 100R15

- SAE 100R16

- SAE 100R17

Can you customize hydraulic hose lengths?

Our hydraulic hoses are typically available in standard lengths of 40, 50, or 100 meters.

However, we understand that every application is unique. That’s why we offer a custom length service tailored to your specific requirements. Whether you need a shorter hose for a tight space or a longer one for a larger system, we can accommodate your needs.

Can you customize hydraulic hose with our own brand?

Yes, absolutely. We can customize hydraulic hoses with your own brand.

We can print your hydraulic hose brand name on the hydraulic hose layline, and also you can choose your desired packing method for your hydraulic hose packaging, include fabric belt, wooden pallets, wooden boxes and etc.

By offering private label hydraulic hoses, you can effectively establish your own brand identity in the market and provide your customers with high-quality, reliable, and uniquely branded products.

What is your Hydraulic hose MOQ?

We understand the needs of local hydraulic hose businesses and are happy to accommodate smaller order quantities. We can accept minimum order quantities (MOQ) as low as 200 meters for many of our standard hydraulic hose products. This flexibility allows you to efficiently meet the demands of your customers while minimizing inventory costs. We strive to be a reliable and supportive partner for businesses of all sizes.

Ask for Quick Quote

Are you looking for a reliable hydraulic hose manufacturer? Here we can provide you all-in-one hydraulic hose solutions for your projects. Please feel free to contact us at any time if you have any questions about our hydraulic hoses.