A hydraulic hose kink is a serious issue that severely restricts fluid flow, generates excessive heat, and leads to premature hose failure. We understand that kinks can damage the internal reinforcement, compromising the hose’s structural integrity. We offer this guide to help you quickly identify the root causes of kinking and implement effective preventative measures right away.

We manufacture and supply hoses designed for durability, but improper installation or routing can negate this quality. Learning the correct handling, minimum bend radius requirements, and fitting placement is crucial. We provide the essential knowledge to ensure your assemblies function flawlessly, maintaining system efficiency and drastically extending service life.

What is a Kinked Hydraulic Hose?

A kinked hydraulic hose occurs when the hose is bent sharply beyond its minimum designated bend radius, causing a permanent deformation or collapse in the hose’s structure.

This physical compression on the inner tube and the reinforcement layers—like the steel wire braid—creates a severe restriction in the fluid path. We consider a kink a point of failure because it dramatically restricts the flow of hydraulic fluid, creating localized pressure spikes and heat generation within the system.

The presence of a kink is extremely detrimental to the entire hydraulic system’s performance and safety. It forces the system to work harder, leading to reduced efficiency and accelerated wear on pumps and valves. Crucially, a kink creates a severe weak point where the hose material and reinforcement are stressed and damaged, making the hose highly susceptible to rupture, bursting, or catastrophic leaks, posing significant safety hazards.

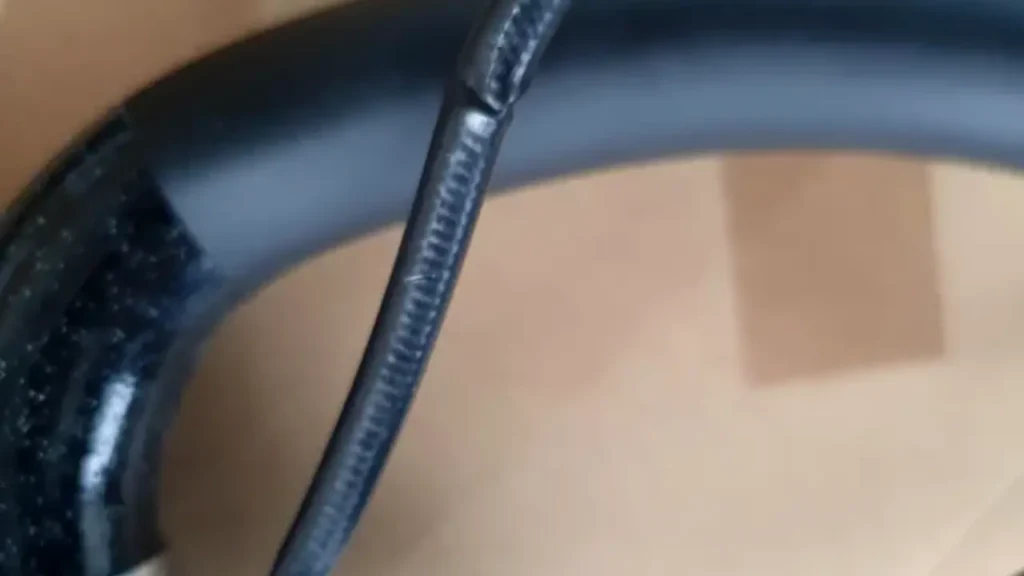

Hydraulic Hose Kink Bubble

A hydraulic hose kink bubble is a critical and dangerous symptom indicating severe internal damage caused by improper bending or routing. This bubble is essentially a bulge that forms where the hose has kinked, signifying that the internal reinforcement layers—like the wire braid—have broken or separated. We want to emphasize that this damage means the hose is no longer safe to operate under pressure and requires immediate replacement.

The integrity of the hose is permanently compromised at the kinked location, allowing the high-pressure fluid to escape its intended containment, pushing the outer cover outwards to form the bubble . We understand that using a hose in this condition is extremely risky. We strongly advise ceasing operations and replacing the component to avoid a catastrophic hose burst and potential injury.

- Reinforcement Failure: We identify that the kinking action stresses the reinforcing wire or fabric layers beyond their elastic limit, causing them to break or shift position. This damage means the hose can no longer contain the system’s internal pressure. We supply hoses with robust reinforcement, but this internal structure is permanently destroyed at the site of the kink.

- Outer Cover Separation: We observe that once the internal pressure is no longer contained by the damaged reinforcement, the fluid forces itself against the inner tube and outer cover. The pressure causes the layers to separate, resulting in a localized bulge or bubble. We provide covers that resist environmental damage, but they cannot contain internal pressure failure.

- Immediate Hazard: We must emphasize that a kink bubble is a clear sign of impending failure and represents an immediate safety hazard. Continuing to operate the hose risks an explosive burst, which can release pressurized fluid and debris at dangerous velocities. We supply replacement hoses and insist on zero tolerance for operating damaged components.

What Causes Hydraulic Hose Kinking?

Understanding the precise reasons behind a hydraulic hose kink is the first step in ensuring your system’s long-term integrity and reliability. Kinking is never accidental; it is a direct consequence of either improper installation techniques or poor initial component selection. We provide these insights so you can proactively address the root causes, eliminating the risk of costly failures and hazardous leaks within your machinery.

We supply hoses engineered for superior performance, yet even the most durable products have limits. The common causes we have identified all involve stressing the hose structure beyond its design parameters, leading to the internal collapse that characterizes a kink. We aim to equip your team with the essential knowledge needed to properly route and manage every hose assembly you deploy.

- Exceeding Minimum Bend Radius: We specify a minimum bend radius for every hose we manufacture, which is the tightest curve the hose can form without structural damage. Bending the hose tighter than this limit forces the inner tube and reinforcement to collapse on the inside of the curve, immediately creating a kink. We recommend using angled fittings to maintain this crucial boundary.

- Improper Hose Length Selection: We find that selecting a hose that is either too short or excessively long frequently leads to kinking. A hose that is too short must be stretched and pulled tight, causing it to sharply collapse near the fittings. Conversely, an overly long hose can easily loop and droop, creating slack that can fold over on itself when pressure is applied.

- Poor Routing or Installation: We observe that running a hose through tight spaces, around sharp corners, or allowing it to hang unsupported often results in kinking. The hose may be forced to bend unnaturally or become snagged, leading to an over-stressed bend point. We emphasize routing that permits natural, gentle flexing and uses clamps for proper support.

- Incorrect Hose Type Used: We offer different hose constructions, some with greater flexibility than others. Using a heavy-duty, high-pressure hose (which has a larger minimum bend radius) in an application that requires tight turns often causes kinking because it simply cannot handle the required flexibility. We provide consultation to ensure you choose the correct flexibility rating.

How to Avoid Hydraulic Hose Kink?

Preventing a hydraulic hose kink is entirely achievable with careful planning and adherence to best installation practices. Kinks are structural failures that severely compromise performance; therefore, proactively following simple routing and selection rules is crucial. We provide these straightforward strategies to help you maintain optimal system flow, extend the service life of your hoses, and prevent expensive equipment downtime.

We supply a diverse range of flexible and rugged hydraulic hoses, but even the best components require correct installation to perform reliably. By focusing on maintaining the minimum bend radius and ensuring proper hose movement, you virtually eliminate the risk of kinking. We empower your team with the practical knowledge needed to install leak-proof and kink-free assemblies every time.

- Respect the Minimum Bend Radius We always advise strictly following the manufacturer-specified minimum bend radius for your hose type. Never bend the hose tighter than this limit; doing so forces the internal structure to collapse. We recommend using elbow fittings or flange fittings to manage tight corners and preserve the hose’s natural curvature during routing.

- Use the Correct Hose Length We emphasize measuring carefully to ensure the hose is long enough to accommodate all system movement without stretching or pulling tight. However, avoid excess slack, as this allows the hose to loop and fold over itself. We guide you to select a length that permits gentle, natural flexing and accounts for the slight changes that occur under pressure.

- Implement Proper Routing Techniques We recommend using clamps, routing guides, and protective sleeves along the hose’s path, especially in dynamic applications. This supports the hose and prevents unnecessary twisting, rubbing, or snagging, which can force the hose into sharp, damaging bends. We supply routing solutions to ensure the hose moves freely but is always under control.

- Install Protective Spiral Wrap We supply plastic spiral wrap covers that not only protect the hose from external abrasion and impact but also reinforce the hose against accidental over-bending. The stiff material helps maintain a larger radius in areas where the hose is prone to being bent too tightly, offering an extra layer of structural protection against kinking.

Tips for Maintaining Your Hydraulic Hoses

Effective maintenance is critical for extending the service life of your hydraulic hoses and ensuring maximum operational uptime. Proactive care helps prevent premature failure, leaks, and catastrophic system damage. We supply comprehensive hydraulic hose solutions, and these simple, actionable maintenance tips we provide will help you achieve maximum reliability and a greater return on your equipment investment.

We manufacture and supply hoses built for demanding environments, but regular inspection and proper care are non-negotiable for long-term performance. By consistently monitoring your hose assemblies for signs of wear and immediately addressing issues, you mitigate the risks of costly downtime. We empower your team with the knowledge to maintain peak system efficiency and safety.

- Regular Visual Inspection We advise performing routine visual checks for common signs of wear, including abrasion, cuts, bulges, leaks near fittings, and cracking of the outer cover. Immediate attention to these issues prevents minor damage from escalating into major failure. We provide guidelines for what constitutes a safe operating condition versus one that requires replacement.

- Check for Proper Routing and Clamping We emphasize verifying that hoses are routed correctly, avoiding sharp bends and contact with moving parts or abrasive surfaces. Ensure all clamps and guides we supply are secure and properly positioned to prevent kinking or excessive twisting. This maintenance step preserves the hose’s structural integrity and prevents external wear.

- Monitor Fluid Compatibility and Temperature We caution against using hydraulic fluids that are incompatible with the hose’s inner tube material, as this causes chemical degradation. Additionally, we advise monitoring operating temperatures, as prolonged exposure to excessive heat accelerates material breakdown and hardening. We provide charts on fluid and temperature compatibility for our hoses.

- Clean and Protect Hose Surfaces We recommend regularly cleaning the external surfaces of the hose to remove corrosive materials, oil residue, and dirt. Where abrasion is unavoidable, ensure any protective sleeves or wraps we supply are intact and functioning correctly. This simple action significantly protects the outer cover from environmental and physical damage.

Conclusion

Preventing a hydraulic hose kink ultimately comes down to meticulous planning and adherence to manufacturer guidelines during installation and maintenance. We have emphasized the importance of observing the minimum bend radius and utilizing appropriate hose routing methods to avoid sharp angles and stress points. We supply the expertise needed to keep your systems operating reliably, avoiding costly failures and unexpected downtime.

By applying these essential avoidance techniques, you protect the internal components of your hose—such as the reinforcement wire—ensuring maximum flow efficiency and integrity. We recommend regular inspection of hose routing in dynamic applications to catch potential kinking issues early. We are committed to providing the durable solutions necessary for your continued operational success and safety.

Ready to secure components that resist damage and deliver reliable performance? Ensure the integrity of your hydraulic system by sourcing your durable hoses and covers from a specialist. We supply a full range of products manufactured to exacting specifications. For dependable, damage-resistant hydraulic hoses, get wholesale hydraulic hoses from our Gushan Rubber. Contact us today for a quote.