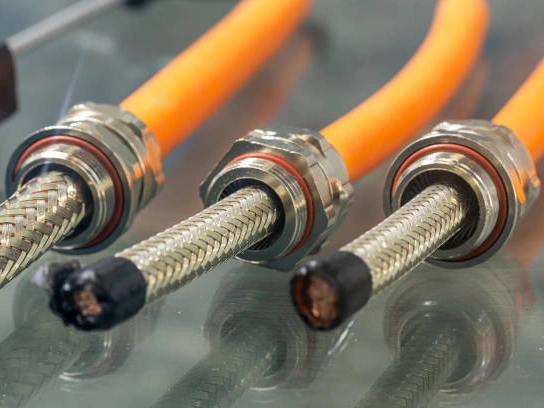

When we’re working on high-performance vehicles or industrial projects, we often encounter stainless steel braided hose. This type of hose is favored for its incredible strength and resistance to high pressure and heat. However, its very toughness makes it challenging to cut cleanly.

A sloppy cut can lead to frayed ends, making it impossible to install fittings properly and potentially compromising the entire fluid system. In this comprehensive guide, we will share the essential techniques and tools we use to achieve a perfect, professional-grade cut every single time.

What is the Best Tool to Cut Stainless Steel With?

Attempting to cut stainless steel braided hose with ordinary tools like scissors or wire cutters is a recipe for frustration. The stainless steel braiding, while flexible, is exceptionally strong and will resist these tools, leading to a crushed and frayed mess.

Abrasive Cut-Off Wheel: This is our preferred method for a perfectly clean and sealed cut. We use a high-speed rotary tool (like a Dremel) or an angle grinder fitted with a thin, abrasive cut-off wheel. The high speed and friction effectively melt the stainless steel threads as they cut, preventing any fraying. This method requires a stable work surface and safety gear, as sparks will be generated.

Hydraulic Hose Cutter: For a quick, clean cut without sparks, a specialized hydraulic hose cutter is an excellent choice. These tools use a powerful shearing action to cut through the hose. While more expensive, they provide a consistent, straight cut without the risk of fraying or crushing the hose. They are ideal for workshops that handle high volumes of hose work.

Hacksaw with a Fine-Tooth Blade: A hacksaw can work in a pinch, but it’s not our first choice. To use this method effectively, we must stabilize the hose and apply firm, even pressure. It will leave a raw, unsealed edge, so we always wrap the hose tightly with tape beforehand to prevent the braid from unraveling. It is the most labor-intensive and least tidy method on this list.

How Do We Prepare the Hose?

Proper preparation is the most critical step to getting a perfect cut. The goal is to stabilize the hose and prevent the braid from unraveling. We never start cutting without first taking a few moments to prepare the hose.

First, we carefully measure and mark the exact length we need. We use a permanent marker to draw a clear line around the hose. Next, we apply high-quality electrical tape or masking tape tightly around the hose, right on our marked line. We make sure to wrap the tape a few times, compressing the braid firmly. This tape acts as a barrier, holding the steel threads in place and ensuring they don’t unravel when the cutting tool makes contact.

How to Cut Stainless Steel Braided Hose

Step 1: Measure and Secure

We always measure the hose twice to avoid mistakes. Once we have our exact length, we mark the spot with a permanent marker. We then secure the hose firmly in a vise, making sure the marked section is accessible and the hose is straight and not twisted.

Step 2: Tape it Tightly

With the hose secured, we take our electrical tape and wrap it tightly around the hose directly on the marked line. We apply tension as we wrap to compress the stainless steel braid as much as possible. This is the most crucial step for preventing fraying and ensuring a clean cut.

Step 3: Make the Cut

Now it’s time to cut. We choose our tool based on availability and the desired result.

- Using an Abrasive Cut-Off Wheel: Wearing safety glasses and gloves, we turn on the tool and slowly guide the wheel through the taped section of the hose. We let the wheel’s speed and abrasive nature do the work, applying light, steady pressure. The heat from the cut will seal the ends of the braid, preventing any fraying.

- Using a Hydraulic Hose Cutter: We simply place the taped hose within the jaws of the cutter, aligning the blade with the tape. We then pump the handle to activate the hydraulic action, making a quick, clean slice through the hose.

- Using a Hacksaw: We place the taped hose on a stable surface. Using a fine-tooth hacksaw, we begin to saw through the taped section with a smooth, even motion. We apply steady pressure and work slowly to avoid deforming the hose.

Step 4: Clean and Inspect

After cutting, the tape should be carefully removed. The cut should be clean, and the braid should be intact. We’ll gently deburr the inside and outside edges of the hose with a small file or sandpaper. Inspect the cut to ensure there are no stray strands of wire that could contaminate our fluid system. A quick purge with compressed air can also help remove any remaining debris.

Does a Quality Cut Affect Performance?

Absolutely. A high-quality cut is the first and most vital step toward a reliable, leak-free connection. When the end of the hose is clean and not frayed, it allows the fitting to engage and seal correctly. A messy or crushed end can prevent the threads from catching or can damage the fitting itself. This can lead to leaks, premature hose failure, and potentially dangerous system failures.

Taking a few extra minutes to make a proper cut with the right tools ensures that your entire project is built on a solid, reliable foundation. It’s a small detail that provides peace of mind and long-term performance.

Conclusion

Properly cutting stainless steel braided hose is a short but crucial step that is crucial to the performance and safety of your fluid system. If you have questions about stainless steel braided hose, please contact us for free.