Hydraulic hoses are vital components in machinery, responsible for transferring pressurized fluid to perform lifting, tilting, and other critical functions. Over time, hoses can wear, crack, or leak, affecting efficiency and safety. Understanding when to replace them helps prevent unexpected failures, downtime, and costly repairs in industrial and forklift applications.

Regular inspection and maintenance are essential for prolonging hose life. Factors such as pressure, temperature, and usage frequency influence hose durability. By recognizing warning signs and following recommended replacement intervals, operators can ensure smooth operation, reduce hazards, and maintain optimal hydraulic system performance across all equipment and attachments.

How Often Should You Replace Hydraulic Hoses

Knowing how often to replace hydraulic hoses is essential for safe and efficient equipment operation. Worn or damaged hoses can cause leaks, pressure loss, or complete system failure, leading to downtime and costly repairs. Regular replacement ensures optimal hydraulic performance, protects machinery, and maintains workplace safety across forklifts, industrial machinery, and other hydraulic systems.

- Follow Manufacturer Guidelines: Most manufacturers provide recommended replacement intervals based on hours of operation or years of service. Adhering to these guidelines ensures hoses are replaced before failure occurs. Proper compliance reduces unexpected downtime, extends the life of connected equipment, and maintains consistent hydraulic performance across all applications.

- Monitor Hose Condition: Regular visual inspections help detect wear, cracks, bulges, or leaks. Catching these signs early prevents major failures and ensures continued system efficiency. Maintaining a detailed inspection log allows operators to plan replacements proactively and avoid emergency shutdowns, keeping machinery reliable and safe.

- Consider Operating Conditions: Hoses exposed to extreme pressure, heat, or harsh environments may require more frequent replacement. Understanding the operating conditions allows for proactive maintenance scheduling. Selecting hoses designed for these conditions further enhances durability, preventing premature failure and ensuring uninterrupted hydraulic performance in demanding applications.

- Evaluate Usage Frequency: Heavy-duty or continuous-use machinery may wear hoses faster than lightly used equipment. Tracking usage patterns helps determine replacement intervals. By aligning maintenance with operational demands, businesses can optimize hose lifespan, reduce costs, and maintain safety and performance standards for all hydraulic systems.

- Replace After Repairs or Damage: Any hose involved in a repair, accident, or mechanical issue should be replaced immediately. Even minor damage can compromise system integrity, causing leaks or pressure loss. Prompt replacement after incidents ensures continued reliability, protects machinery, and reduces the risk of operational hazards.

How Many Years Do Hydraulic Hoses Last?

The hydraulic hose shelf life can vary significantly depending on several factors, including:

- Operating Conditions: Factors like temperature, pressure, vibration, and exposure to chemicals can significantly impact the hose’s lifespan.

- Maintenance: Regular inspection and replacement of worn hoses can extend their life.

- Hose Material and Type: Different materials and types of hoses have varying lifespans.

Generally, hydraulic hoses can last between 5 to 10 years under normal operating conditions. However, it’s important to note that this is just an estimate, and the actual lifespan can be shorter or longer.

To maximize the lifespan of your hydraulic hoses, consider the following:

- Regular Inspection: Conduct regular visual inspections for signs of wear, such as cracks, cuts, or leaks.

- Proper Installation: Ensure hoses are installed correctly to avoid kinking or excessive stress.

- Avoid Extreme Conditions: Protect hoses from extreme temperatures, excessive vibration, and exposure to harmful chemicals.

- Replace Worn Hoses Promptly: Replace any damaged or worn hoses immediately to prevent accidents and downtime.

By following these guidelines, you can significantly extend the life of your hydraulic hoses and ensure the smooth operation of your equipment.

Hydraulic Hose Replacement Cost

The cost to replace a hydraulic hose can vary significantly depending on several factors, including:

- Hose length and diameter: Longer and larger diameter hoses typically cost more.

- Hose material and type: The specific material and type of hose (e.g., rubber, wire braid, or thermoplastic) will influence the price.

- Fittings and adapters: The type and complexity of the fittings and adapters required can impact the cost.

- Labor costs: The labor cost will vary depending on the mechanic’s hourly rate and the complexity of the job.

- Vehicle make and model: Different vehicles have different hose lengths, fittings, and installation complexities.

Generally, the cost to replace a hydraulic hose, including parts and labor, can range from $20 to $300 or more. However, it’s important to note that this is just an estimate, and the actual cost may be higher or lower depending on specific factors.

To get an accurate estimate for your specific vehicle, it’s best to consult with a local mechanic or auto repair shop. They can provide you with a precise quote based on your vehicle’s make and model, as well as any additional services required, such as bleeding the clutch system.

For those who are mechanically inclined, it’s possible to replace a hydraulic clutch hose yourself. This can save on labor costs, but it requires specific tools and knowledge. It’s important to consult your vehicle’s service manual or a repair guide to ensure proper installation and bleeding of the clutch system.

Remember, a properly functioning clutch hose is essential for safe and efficient driving. If you notice any signs of a failing clutch hose, such as fluid leaks, difficulty shifting gears, or a spongy clutch pedal, it’s important to have it replaced promptly.

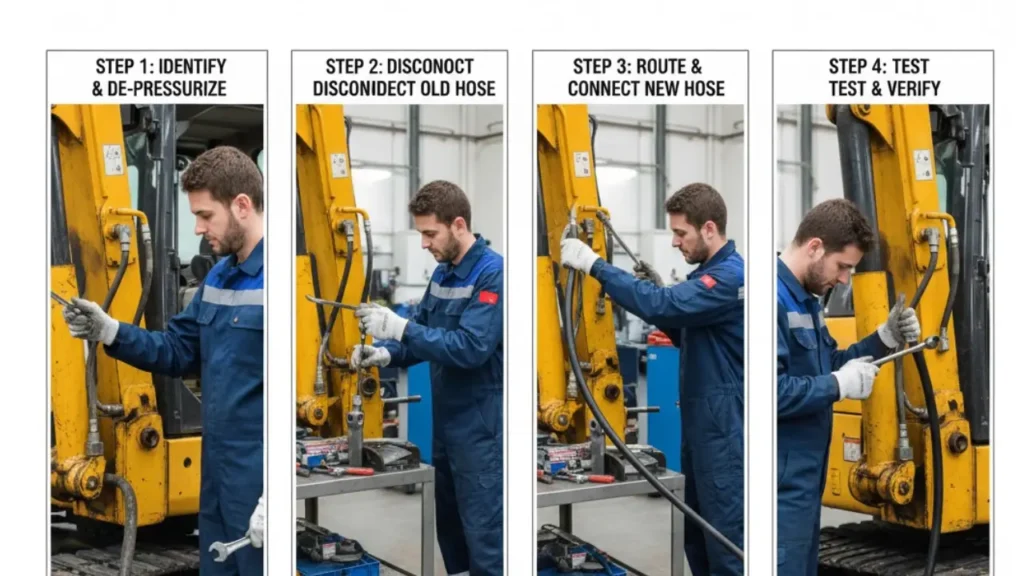

Hydraulic Hose Replacement Procedure

Hydraulic hose replacement is essential for maintaining safe and efficient hydraulic system operation. Proper procedures prevent leaks, pressure loss, and equipment damage while ensuring reliable performance. Following a systematic replacement process minimizes downtime and protects both machinery and operators, keeping forklifts and other hydraulic machinery running smoothly under demanding conditions.

Tools Needed

- Wrenches (adjustable and fixed)

- Hydraulic fluid

- Hose clamps and fittings

- Safety gloves and goggles

- Clean rags

- Container for old hydraulic fluid

Step 1: Shut Down and Depressurize System

Before replacing a hydraulic hose, fully shut down the equipment and relieve all system pressure. Depressurizing prevents fluid spray, injuries, and equipment damage. Following safety protocols ensures a controlled environment, allowing the operator to remove old hoses without risk while preparing for smooth installation of new hydraulic hoses.

Always wear protective gear during this step. Identify the hose to be replaced and check surrounding components for potential hazards. Using rags or a container, catch any residual hydraulic fluid. Taking these precautions reduces contamination risk and keeps the workspace clean, ensuring safety and efficiency throughout the replacement process.

Step 2: Remove the Old Hose

Loosen hose fittings carefully using appropriate wrenches. Disconnect the hose from the hydraulic system, taking care to avoid damage to connectors or adjacent components. Proper removal ensures no debris enters the hydraulic system and prevents leaks, maintaining system integrity and avoiding future performance issues.

Collect the old hose and fittings for inspection or disposal. Examine connectors for wear or damage and replace them if necessary. Cleaning the connection points before installing a new hose prevents contamination, ensuring reliable performance. This step prepares the system for proper installation, reducing the likelihood of leaks or malfunctions.

Step 3: Install the New Hose

Position the new hydraulic hose in the correct orientation and attach fittings securely. Ensure proper routing to avoid kinks, twists, or contact with moving parts. Correct installation maintains smooth hydraulic flow, reduces wear, and ensures safe operation, extending the life of both the hose and connected machinery.

Tighten fittings to the manufacturer’s recommended torque specifications. Verify that the hose has enough slack for system movement while avoiding excessive bends. Double-check connections and routing before pressurizing the system. Proper installation guarantees reliable performance, minimizes maintenance issues, and maintains the safety of operators during hydraulic system operation.

Step 4: Test the System

After installation, slowly pressurize the hydraulic system and check for leaks or abnormal behavior. Observe hose movement and connection points under operating pressure to ensure stability and proper function. Testing confirms the replacement was successful and the system is operating safely and efficiently.

Run the equipment through normal operations and monitor for unusual sounds or movements. Address any issues immediately to prevent damage. Document the replacement and inspection results for maintenance records. Regular testing ensures long-term reliability, prolongs hose life, and maintains optimal performance of forklifts and other hydraulic machinery.

What is the Life Expectancy of a Hydraulic Hose?

The life expectancy of a hydraulic hose depends on factors like operating pressure, temperature, fluid type, and frequency of use. Regular inspection and proper maintenance can significantly extend hose life, while neglect or harsh operating conditions can cause premature failure. Understanding lifespan helps plan replacements, prevent downtime, and maintain safe hydraulic system performance.

- Operating Pressure: Hoses subjected to pressures above their rated limits wear out faster. Maintaining pressure within manufacturer specifications reduces stress, prevents ruptures, and ensures consistent performance. Regular monitoring of system pressure helps identify overloads early, extending the hose’s operational lifespan and preventing unexpected failures.

- Temperature Exposure: High or fluctuating temperatures can degrade hose materials, causing cracks or leaks. Using hoses rated for specific temperature ranges ensures stability. Proper routing and insulation reduce heat exposure, while cooling systems or protective sleeves help maintain the hose’s structural integrity over prolonged operation.

- Hydraulic Fluid Compatibility: The type of hydraulic fluid used affects hose longevity. Incompatible fluids can degrade hose material, causing swelling or softening. Always select hoses compatible with your fluid type, and periodically check for chemical damage. This ensures safe operation, consistent pressure delivery, and longer hose life.

- Frequency of Use: Hoses in continuously operating machinery experience more wear than infrequently used hoses. Heavy-duty applications require more frequent inspections and earlier replacements. Tracking operating hours and usage patterns allows proactive maintenance, preventing unexpected failures and ensuring reliable performance for all hydraulic systems.

- Environmental Factors: Exposure to abrasion, UV light, chemicals, or moisture can reduce hose lifespan. Protective sleeves, proper routing, and regular cleaning minimize environmental impact. By safeguarding hoses from external damage, you ensure they maintain their pressure rating and functionality, providing long-term reliability.

Hydraulic Hose Life Expectancy Chart:

| Factor | Low Impact | Moderate Impact | High Impact | Expected Hose Life |

|---|---|---|---|---|

| Operating Pressure | Within rating | 10-20% over | >20% over | 5-7 years |

| Temperature Exposure | <60°C | 60-90°C | >90°C | 3-5 years |

| Fluid Compatibility | Compatible | Slightly incompatible | Incompatible | 4-6 years |

| Usage Frequency | Light | Moderate | Heavy | 2-5 years |

| Environmental Factors | Indoor, protected | Occasional exposure | Harsh/outdoor | 2-4 years |

Conclusion

Timely replacement of hydraulic hoses is crucial to maintaining equipment safety and efficiency. Ignoring wear or leaks can lead to system failures, operational delays, and increased repair costs. Monitoring hose condition and following manufacturer guidelines ensures reliable performance and minimizes downtime in industrial, construction, and forklift applications. Get wholesale hydraulic hoses from our Gushan Rubber.

By establishing a regular inspection and replacement routine, operators can extend the life of both hoses and connected equipment. Early detection of cracks, bulges, or leaks prevents emergencies and costly damage. Investing in quality hoses and adhering to maintenance schedules keeps machinery running smoothly. Get wholesale hydraulic hoses from our Gushan Rubber.

Choosing the right replacement hoses is just as important as timing. Selecting durable, high-pressure-rated hoses ensures long-term reliability and safety. With access to bulk hydraulic hoses, businesses can maintain uninterrupted operations while reducing procurement costs. Trust Gushan Rubber for consistent, high-performance wholesale hydraulic hoses for all your industrial needs.