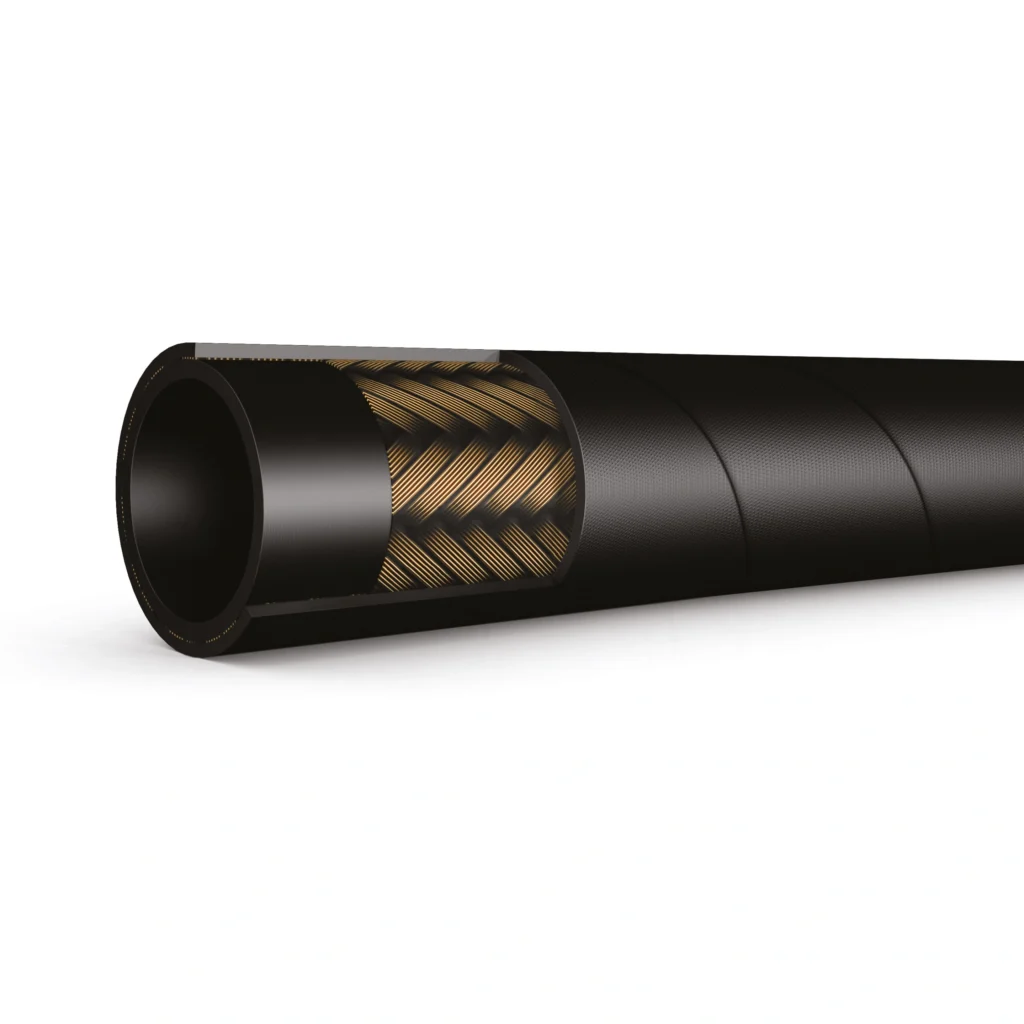

Braided Wire Hose

At Gushan Rubber, we specialize in manufacturing braided wire hoses designed for demanding hydraulic applications. Our hoses are engineered with a durable inner core and reinforced with one or two layers of high-tensile braided steel wire, offering superior pressure resistance and exceptional durability. We offer wholesale pricing and custom solutions to meet your specific needs.

Get Your Desired Braided Wire Hose

Gushan Rubber offers a comprehensive range of braided wire hoses to meet your specific hydraulic requirements. Our products are engineered with a durable synthetic rubber tube and reinforced with high-tensile steel wire braiding for superior performance under extreme pressure. We can provide custom manufacturing solutions for any project, ensuring you get the exact hose you need. Contact us for a quote today!

All Braided Wire Hoses

PVC steel wire braided hose

At Gushan Rubber, we specialize in manufacturing PVC wire braided flexible hose pipe. Our hoses are engineered with a flexible PVC wall and a helix of strong steel wire for superior strength, kink resistance, and durability. Ideal for both suction and discharge, they are perfect for a wide range of industrial and agricultural applications.

steel wire braided hose

Gushan Rubber offers a comprehensive range of steel wire braided hoses, including standard SAE 100R1AT and 100R2AT. Engineered with a robust inner tube and one or two layers of high-tensile steel wire braiding, our hoses are designed for superior performance. They provide excellent resistance to pressure, abrasion, and kinking, ensuring safety and longevity in demanding applications.

Spiral Braided Wire Hose

Unlike braided hoses that use a crisscross weave, spiral hoses are reinforced with layers of steel wire wrapped in opposing spirals. A spiral braided wire hose is often considered more flexible than a traditional braid, and it is a preferred choice for dynamic applications where the hose is subject to constant flexing and bending. This design helps to prevent metal fatigue and extends the hose’s working life under demanding conditions.

Stainless Steel Braided Wire Hose

The stainless steel braided wire hose is an excellent choice for environments that require resistance to corrosion, high temperatures, and chemical exposure. The stainless steel braiding not only provides strength but also resists rust and degradation from harsh external elements. This makes it a popular product in the food and beverage industry, chemical processing plants, and marine applications where cleanliness and corrosion resistance are top priorities.

PTFE Lined Braided Wire Hose

This specialized hose features an inner tube made of PTFE (Teflon), which is then reinforced with a braided wire layer. The PTFE liner provides superior chemical compatibility and a smooth, non-stick surface, making it ideal for transporting corrosive chemicals or food products that need to avoid contamination. The wire braid adds the necessary pressure rating, combining the best of both worlds for challenging applications.

High-Pressure Hydraulic Braided Wire Hose

A specific type of High-Pressure braided wire hose engineered for hydraulic systems. These hoses are built to withstand immense pressure and are typically found in heavy-duty machinery. The robust construction is tailored to handle the force generated by hydraulic fluids, ensuring reliable power transmission and safe operation in demanding applications like excavators, forklifts, and cranes.

Custom Braided Wire Hose Wholesale

Unmatched Durability for High-Pressure Applications

The defining feature of a braided wire hose is its ability to handle intense pressure without failing. The braided reinforcement acts as a robust shield, distributing the force evenly across the hose’s length. This prevents the inner tube from ballooning or bursting, which is a common point of failure for non-braided hoses. In industries like heavy machinery, construction, and manufacturing, this durability is non-negotiable, ensuring operations can run smoothly and safely even under extreme conditions.

Flexibility and Kink Resistance

Despite its tough exterior, a high-quality braided wire hose maintains a surprising degree of flexibility. The design allows the hose to bend without kinking, which is a major benefit in complex systems with intricate routing. Kinking can restrict flow and cause a buildup of pressure, leading to premature failure. The reinforcing wires provide structural integrity that prevents these collapses, ensuring a consistent and uninterrupted flow of fluids.

Superior Resistance to Abrasion and External Damage

Beyond pressure resistance, the woven wire sheath protects the inner hose from physical damage. When hoses are routed through tight spaces or are subject to friction from contact with other components, the braided layer significantly reduces the risk of wear. This makes a braided wire hose ideal for dynamic environments where movement and rubbing are common, extending the product’s lifespan and reducing the need for frequent replacements.

Broad Compatibility for Diverse Industrial Use

The versatility of the braided wire hose makes it a go-to solution for a wide range of industries. Whether it’s used to transport hydraulic fluids in construction equipment, compressed air in factory settings, or fuel in automotive engines, its core design remains effective. Different materials for the inner tube and the braided layer allow for customization, ensuring the hose is compatible with a variety of media, temperatures, and environmental conditions.

What is the main benefit of a braided wire hose?

The main benefit of a braided wire hose is its exceptional durability and pressure resistance. The woven wire reinforcement acts as a robust shield, preventing the inner tube from bursting or kinking, which are common points of failure for standard rubber hoses. This enhanced strength reduces the risk of system failure and costly leaks, ensuring your operations run smoothly and safely.

This core design feature makes a braided wire hose a critical safety component in high-pressure systems. By containing the force of the fluid, it protects both expensive machinery and personnel from potential accidents. The reliability it offers provides a significant return on investment by reducing downtime and maintenance costs over the long term.

What is the difference between single and double braid?

The difference lies in the number of woven wire layers. A single braided wire hose is suitable for moderate pressures, while a double-braid hose is designed to handle significantly higher pressures. The double-braid construction provides extra strength and rigidity, making it essential for heavy-duty applications.

Are braided hoses more expensive than standard hoses?

Yes, a braided wire hose typically has a higher initial cost than a standard rubber hose. This is due to the more complex manufacturing process and the use of reinforcing materials like stainless steel. However, it’s important to view this as an investment rather than an expense.

The higher upfront cost is offset by the hose’s significantly longer lifespan and a lower risk of failure. While you might replace a rubber hose every few years, a braided wire hose can last for a decade or more. The long-term savings from avoiding costly repairs and replacements make it a much more economical choice over time.

Can a braided wire hose be used for any fluid?

Not all braided wire hoses are compatible with every fluid. The type of fluid a hose can carry safely depends on the material of the inner tube. For example, a standard rubber-lined hose is great for hydraulic fluid, while a PTFE-lined hose is required for handling corrosive chemicals.

It is crucial to match the hose’s inner tube material to the fluid it will be transporting to prevent degradation, contamination, and premature failure. Always check the manufacturer’s specifications to ensure the hose is chemically compatible with your application. Using the wrong hose can lead to dangerous and costly spills.

Quote Braided Wire Hose Wholesale

Is your project held back by unsuitable hydraulic hoses? Don’t compromise on performance or struggle with ill-fitting components. We offer 3/16 hydraulic hose wholesale, custom-tailored to your exact specifications. Get precise lengths, ideal pressure ratings, and the perfect fittings for seamless integration, ensuring your systems operate with maximum efficiency and reliability, every time.