Braided and spiral hydraulic hoses are both essential for fluid power systems, but their internal construction gives them unique performance characteristics. A braided hose features crisscrossing steel wires, offering flexibility and resistance to kinking. A spiral hose, however, uses layers of spiraled steel wires, making it exceptionally strong and suitable for high-pressure applications.

Understanding the core differences between these two types is critical for choosing the right hose for your specific job. The choice between braided and spiral hoses depends on factors like working pressure, flexibility requirements, and the operating environment. This guide will explore these differences to help you make an informed decision.

What is Spiral Hydraulic Hose?

A spiral hydraulic hose is a type of high-pressure hose used in demanding fluid power systems. Unlike braided hoses that have crisscrossing wire reinforcement, a spiral hose is constructed with multiple layers of steel wire wrapped in a helical, or spiral, pattern. This unique construction makes the hose significantly stronger and more rigid, allowing it to withstand much higher pressures and frequent pressure surges, also known as impulse applications. Due to its robust design, the spiral hose is the go-to choice for heavy-duty machinery.

- Construction: Consists of multiple layers (typically four or six) of steel wire wrapped in a spiral fashion.

- Strength: Designed for extremely high working pressures and pressure spikes, making it ideal for high-impulse applications.

- Flexibility: Generally less flexible than braided hoses due to its layered, rigid construction, resulting in a larger bend radius.

- Applications: Widely used in heavy machinery like excavators, mining equipment, and large earth-moving vehicles.

What is Braided Hydraulic Hose?

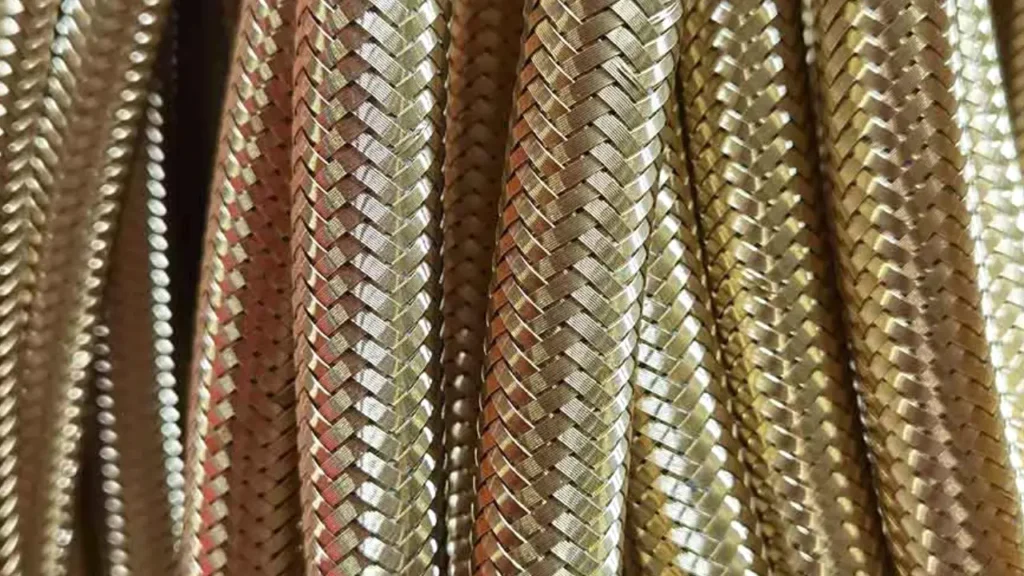

A braided hydraulic hose is a type of hose designed to handle medium to high pressures in fluid power systems. Its key feature is the reinforcement layer, which consists of one or more layers of high-tensile steel wire woven in a crisscrossing, braid-like pattern over the inner tube. This braided design provides significant flexibility and kink resistance, making it ideal for applications that require the hose to bend around tight corners or move frequently. It is the most popular type of hydraulic hose due to its versatility and balanced performance.

- Construction: Features a woven braid of steel wires or synthetic fibers. The crisscrossing pattern gives it strength and flexibility.

- Pressure Rating: Generally used for low to medium-high pressure applications.

- Flexibility: More flexible than a spiral-reinforced hose, allowing for a smaller bend radius and easier routing.

- Applications: Common in a wide range of machinery, including mobile equipment, agricultural machinery, and automotive systems.

Spiral vs Braided Hydraulic Hose

Both braided and spiral hydraulic hoses are designed to withstand high pressure, but they differ significantly in construction and performance. The choice between them depends entirely on the application’s specific requirements, such as working pressure, flexibility needs, and environmental conditions. Knowing their differences is key to ensuring safety and efficiency.

Braided hoses use crisscrossing wire reinforcement for flexibility, making them ideal for dynamic systems. Spiral hoses, with their layered, helical wire construction, are more rigid and designed for extreme high-pressure and high-impulse applications in heavy-duty machinery.

Construction

A braided hose features one or more layers of woven steel wire. This crisscross pattern allows the hose to bend and flex easily, which is why it’s a popular choice for mobile equipment. The interwoven wires provide a balanced combination of strength and flexibility.

In contrast, a spiral hose is reinforced with multiple layers of steel wire wrapped in a tight spiral. These layers are not interwoven, which makes the hose exceptionally strong and rigid. This construction is designed specifically to handle very high pressures and intense pressure spikes without expanding.

Pressure Rating

Braided hoses are typically used for low to medium-high pressure applications. While they are very strong, their interwoven structure is less effective at resisting constant, extreme pressure compared to spiral hoses. As the hose’s diameter increases, its pressure rating generally decreases.

Spiral hoses are the industry standard for extremely high-pressure applications, often found in heavy-duty machinery. Their layered spiral design makes them highly resistant to both constant pressure and high-frequency pressure impulses. The pressure rating on a spiral hose remains consistent regardless of its diameter.

Flexibility and Bend Radius

Braided hoses are known for their superior flexibility and smaller bend radius. This makes them much easier to route through tight spaces and around obstacles, which is a major advantage in compact systems like those found in agricultural or automotive equipment.

Spiral hoses are significantly less flexible and have a larger minimum bend radius. Their rigid construction, while providing immense strength, makes them difficult to bend. This trade-off means they are best suited for applications where the hose can be routed in a relatively straight line with few turns.

Durability and Impulse

Braided hoses are more susceptible to wear from high-impulse applications (rapid pressure changes). The continuous expansion and contraction can cause friction between the braided wires, leading to a loss of strength and premature failure over time.

Spiral hoses are specifically designed to resist the damaging effects of pressure impulses. The layered spiral wires handle pressure changes more effectively, making them far more durable in demanding environments with frequent pressure spikes, such as mining or construction.

Cost

Braided hoses are generally more cost-effective to produce and, as a result, are typically less expensive. Their manufacturing process is less complex than that of spiral hoses, making them a more economical choice for systems that do not require maximum pressure ratings.

Spiral hoses are more expensive due to their complex, multi-layered construction and the higher-quality materials required to withstand extreme pressures. The higher cost is justified by their superior performance and durability in the most demanding and critical applications.

| Feature | Braided Hydraulic Hose | Spiral Hydraulic Hose |

| Reinforcement | Woven/Crisscrossing steel wire | Layered, spiral-wrapped steel wire |

| Working Pressure | Low to medium-high | Extremely high |

| Flexibility | High | Low |

| Bend Radius | Small | Large |

| Applications | General industrial, agricultural, automotive | Heavy-duty, mining, construction |

How to Choose Spiral and Braided Hydraulic Hoses?

Choosing between spiral and braided hydraulic hoses comes down to matching the hose’s capabilities to your application’s specific demands. The primary factors to consider are the required working pressure and the flexibility needed for the system. Braided hoses are your best bet for general-purpose applications that require flexibility and can handle medium pressures, like those found in agricultural or automotive equipment. Spiral hoses, on the other hand, are the go-to for heavy-duty, high-pressure applications with frequent pressure spikes, such as in construction or mining machinery.

- Pressure Rating: If your system operates at extremely high pressures (often above 3000 PSI) or experiences frequent pressure surges, a spiral hose is the superior choice due to its layered construction and resistance to impulse. For low to medium-high pressures, a more flexible braided hose is usually sufficient.

- Flexibility & Routing: Consider how the hose will be routed. Braided hoses are significantly more flexible and have a smaller bend radius, making them easier to install in tight spaces. Spiral hoses are more rigid, so they are better for straight-line connections or applications where flexibility is not a primary concern.

- Cost: Braided hoses are generally more cost-effective to produce and purchase. The higher cost of spiral hoses is justified by their superior strength and durability in extreme environments.

Conclusion

The reinforcement layer defines the performance of hydraulic hoses. We manufacture braided hoses using woven steel wire layers, providing superior flexibility and a lighter profile. This design is optimal for medium-pressure systems and applications needing frequent, tight bending, like standard agricultural machinery.

We design spiral hoses with multiple layers of spirally wound steel wire, creating a much stronger, stiffer structure. We supply these hoses for extremely high-pressure, heavy-duty applications. Their construction offers excellent resistance to continuous pressure impulses in large mining and construction equipment.

The key difference is the performance trade-off. Braided hoses offer greater flexibility and ease of installation for lower pressures. Spiral hoses provide immense strength and superior impulse durability for the harshest environments, though they are more rigid and less easy to route.

For a vast selection of durable and pressure-rated fluid conveyance solutions, contact us. We supply wholesale hydraulic hoses—including both flexible braided and ultra-strong spiral options—directly through Gushan Rubber.