As experts and suppliers in the hose industry, we frequently encounter questions about various piping materials. One of the most common and versatile products among these is the PVC hose. Whether in daily life or across diverse industrial applications, PVC hoses play an indispensable role, silently conveying liquids, gases, and granular materials for us.

What is a PVC Hose?

PVC hose is a flexible tube made of polyvinyl chloride (PVC). PVC itself is a thermoplastic polymer, and by adding plasticizers, stabilizers, and other additives, it can be made soft, flexible, and give it excellent processing properties.

It is the flexibility of this material that enables PVC hose to be widely used in various occasions that require bending, adapt to different shapes, and withstand a certain amount of pressure.

How is a PVC Hose Manufactured?

When we discuss the manufacturing process of PVC hose, we typically think of extrusion molding technology. This process determines the hose’s structure and performance, enabling it to meet various demanding application requirements. Through precise control and advanced processes, we are able to produce PVC hoses of various types and specifications, ensuring their reliability in different environments. So, how specifically is a PVC hose manufactured?

The manufacturing of PVC hose typically involves an extrusion molding process:

- Raw Material Mixing: First, PVC resin powder is precisely proportioned and mixed with additives such as plasticizers (to impart flexibility), stabilizers (to prevent thermal degradation), lubricants, and colorants.

- Melt Extrusion: The mixed material is fed into an extruder, where, under heat and the shearing action of a screw, the PVC mixture melts into a uniform, plasticized state.

- Die Forming: The molten PVC is extruded through a die, forming a continuous tubular structure. The shape and size of the die determine the hose’s inner diameter and wall thickness.

- Cooling and Shaping: The extruded hot hose immediately enters a cooling water trough or air cooling device, where it quickly cools and solidifies into its final shape, maintaining dimensional stability.

- Reinforcement Layer Addition (Optional): For hoses requiring higher pressure resistance or better anti-kinking properties, a reinforcement layer may be added during the extrusion process. Common reinforcement methods include:

- Fiber Braiding: Polyester, nylon, or other synthetic fibers are braided and embedded between the inner and outer layers of the hose, providing radial strength and improving pressure resistance.

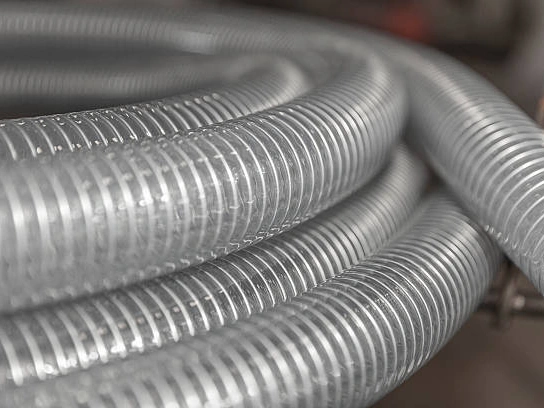

- Spiral Winding: A rigid PVC helix or steel wire helix is embedded, providing axial support and enhancing resistance to vacuum collapse and crushing, commonly used in suction hoses.

- Cutting and Coiling: The formed and cooled hose is cut into predetermined lengths and then coiled for packaging.

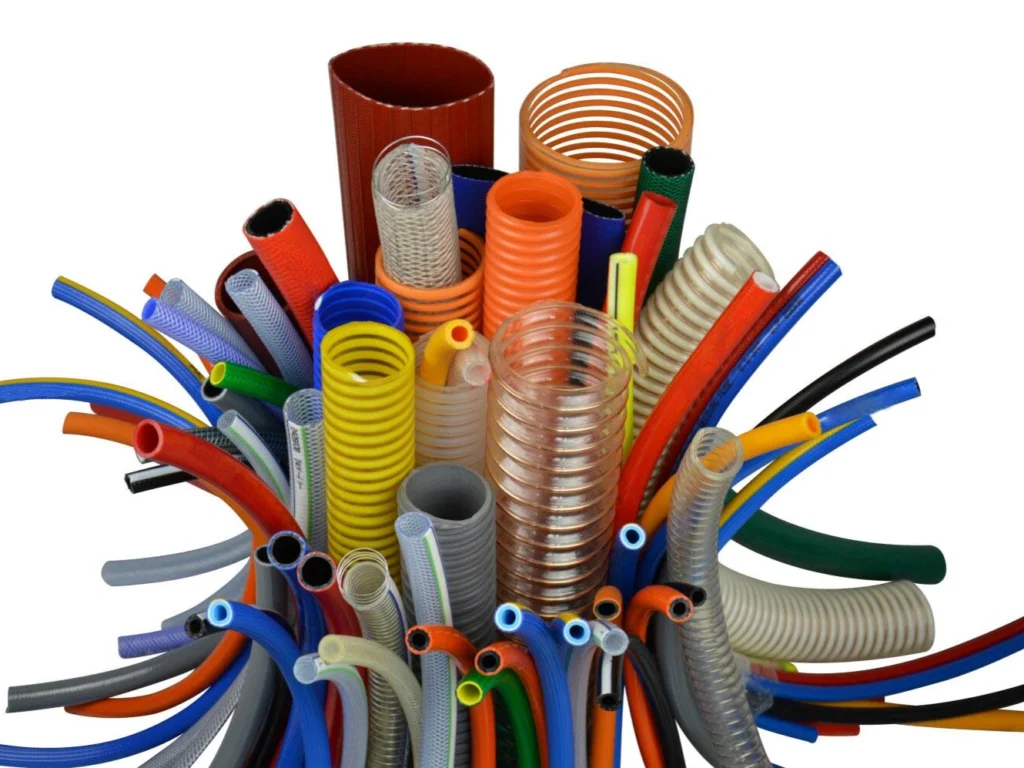

What Are the Main Types of PVC Hose?

In our product range, we find that PVC hose comes in various types, each optimized for specific application scenarios. Understanding these different types helps us recommend the most suitable solution for our clients, ensuring performance and efficiency in diverse and complex environments. So, what are the main types of PVC hose we typically encounter?

PVC hoses are generally classified based on their structure, reinforcement method, and intended use:

- Clear PVC Hose:

- Characteristics: The most common type, usually without a reinforcement layer, offering good transparency to clearly observe fluid flow. It is highly flexible and cost-effective.

- Applications: Home gardening, low-pressure liquid transfer, laboratories, food-grade applications (must comply with relevant standards).

- Braided/Reinforced PVC Hose:

- Characteristics: Features a polyester or nylon fiber braided reinforcement layer between the inner and outer layers, significantly increasing pressure resistance and tensile strength. It is typically opaque or semi-transparent.

- Applications: Industrial water hoses, air hoses, oil hoses, spray hoses, high-pressure washing hoses, garden hoses, suitable for medium to high-pressure environments.

- PVC Suction Hose / Spiral Reinforced PVC Hose:

- Characteristics: Has a rigid PVC helix or steel wire helix embedded within, providing excellent resistance to vacuum collapse (negative pressure) and crushing, while maintaining flexibility. It is usually opaque.

- Applications: Agricultural irrigation, industrial water suction, sewage discharge, granular material transfer, vacuum cleaning, suitable for suction and transfer of heavy fluids or solids.

- PVC Layflat Hose:

- Characteristics: Made from high-strength polyester yarn and PVC compound extruded together, without a rigid skeleton. It can be flattened and coiled when not pressurized, making it easy to store and transport. It offers high-pressure resistance.

- Applications: Agricultural irrigation, fire fighting, construction site dewatering, temporary water transfer lines, suitable for high-volume, temporary transfer.

- PVC Steel Wire Reinforced Hose:

- Characteristics: Features an embedded spiral steel wire, providing extremely strong resistance to negative pressure and crushing, along with a good bending radius. It offers good abrasion and corrosion resistance.

- Applications: Industrial vacuuming, woodworking machinery, food transfer.

What Are the Advantages of PVC Hose?

PVC hose stands out among many pipe materials and is widely used in various fields because it has a series of significant advantages. These characteristics make it an economical, efficient and reliable choice in many application fields.

- Excellent Flexibility: PVC hoses offer outstanding flexibility, making them easy to bend and install. They can adapt to various complex routing environments, reducing the need for additional fittings.

- Good Chemical Resistance: PVC material shows good resistance to many acids, alkalis, salt solutions, and some organic solvents, making it suitable for conveying various chemical media.

- High Cost-Effectiveness: Compared to rubber or metal hoses, PVC hoses generally have lower production costs, making them an ideal choice for budget-conscious applications that still require certain performance levels.

- High Transparency (for some types): Many PVC hoses are transparent, allowing users to clearly observe the flow of internal fluids, which is convenient for monitoring and troubleshooting.

- Lightweight and Portable: PVC hoses are typically lighter than equivalent rubber or metal hoses, making them easier to handle, install, and store, especially in situations requiring frequent movement.

- Abrasion and Weather Resistance: Specially treated PVC hoses exhibit good abrasion resistance, capable of withstanding wear and tear from daily use. Additionally, they have a certain resistance to UV light and various weather conditions, making them suitable for outdoor use.

- Easy to Process and Connect: PVC hoses are easy to cut, connect, and seal, and can be installed using various standard fittings and clamps, greatly simplifying the installation process.

- Non-toxic and Odorless (Food Grade): Specially formulated food-grade PVC hoses comply with strict hygiene standards, making them safe for use in the food, beverage, and pharmaceutical industries.

Applications of Pvc Hoses

From everyday household use to heavy industry, PVC hose, with its unique combination of properties, has become an indispensable conveying solution for many sectors.

The wide application areas of PVC hose include:

- Agricultural Irrigation:

- Uses: Employed in irrigation systems for farmlands, orchards, and greenhouses, conveying water, liquid fertilizers, and pesticides.

- Characteristics: Spiral reinforced suction hoses are often used for drawing water from sources, while layflat hoses are used for main pipeline transfer. Their lightweight, abrasion-resistant, and weather-resistant properties make them ideal.

- Industrial Production:

- Uses: Used in factories to convey water, air, oils, chemicals, granular materials, powders, and slurries.

- Characteristics: Braided PVC hoses are commonly used for pneumatic tools, cooling systems, and general liquid transfer; steel wire reinforced hoses are used for vacuuming, material conveying, and vacuum applications.

- Construction:

- Uses: Utilized for construction site dewatering, concrete pumping (special abrasion-resistant PVC), temporary water supply lines, and ventilation/exhaust.

- Characteristics: Layflat hoses are popular due to their ease of deployment and storage; spiral suction hoses are used for water extraction.

- Household and Gardening:

- Uses: Garden watering, car washing, drainage, connecting household appliances (e.g., washing machine drain hoses).

- Characteristics: Clear PVC hoses and braided garden hoses are preferred for their flexibility, lightness, and ease of handling.

- Food and Beverage Industry:

- Uses: Conveying drinking water, milk, juices, beer, wine, and other food-grade liquids.

- Characteristics: Must use food-grade PVC hoses that comply with strict hygiene standards like FDA, EU regulations, ensuring they are non-toxic, odorless, and do not affect food quality.

- Medical and Laboratory:

- Uses: Transferring medical fluids, gases, connecting medical equipment, and various liquid transfers in laboratories.

- Characteristics: Requires medical-grade PVC hoses that are highly transparent, non-toxic, chemically resistant, and easy to sterilize.

- Ventilation and Dust Collection:

- Uses: Used in industrial vacuum cleaners, woodworking machinery, granular material conveying systems, and ventilation equipment for suctioning dust, particles, and fumes.

- Characteristics: Spiral reinforced or steel wire reinforced PVC hoses are widely used due to their excellent vacuum resistance and abrasion resistance.

How to Choose the Right PVC Hose?

When selecting a PVC hose for a specific application, we understand that it’s not a simple decision. Choosing the wrong hose can lead to poor performance, reduced lifespan, and even safety hazards. Therefore, we need to consider multiple factors comprehensively to ensure that the selected hose perfectly matches the working environment and the fluid media. So, how should we go about choosing the most suitable PVC hose?

- Working Pressure and Burst Pressure:

- Consideration: What is the maximum working pressure the hose needs to withstand? Ensure the selected hose’s working pressure rating is higher than the maximum pressure in the actual application. Burst pressure is typically 3-4 times the working pressure, providing a safety margin.

- Recommendation: For high-pressure applications, choose braided or steel wire reinforced types.

- Temperature Range:

- Consideration: What are the minimum and maximum temperatures of the fluid and the environment? PVC hoses typically have an applicable temperature range (e.g., -5°C to +65°C). Exceeding this range can cause the hose to harden, become brittle, or soften.

- Recommendation: For extreme temperatures, other materials might need to be considered.

- Chemical Compatibility:

- Consideration: What type of fluid will the hose be conveying? PVC has good resistance to acids, alkalis, salt solutions, and water, but may not be compatible with certain solvents, oils, or fuels.

- Recommendation: Consult a chemical compatibility chart to ensure the hose material will not be corroded or degraded by the conveyed medium.

- Flexibility and Bend Radius:

- Consideration: Does the application require the hose to bend frequently? Is installation space limited?

- Recommendation: Clear PVC hoses offer the best flexibility; spiral reinforced hoses have a larger bending radius but are crush-resistant.

- Inner Diameter and Flow Rate:

- Consideration: What volume of fluid needs to be conveyed? What are the flow rate requirements?

- Recommendation: Choose an appropriate inner diameter to ensure the required flow rate while avoiding excessive pressure drop.

- Abrasiveness:

- Consideration: If conveying granular materials, powders, or abrasive media, does the inner wall of the hose need to have high abrasion resistance?

- Recommendation: Steel wire reinforced or hoses with thicker inner walls are generally more abrasion-resistant.

- Certifications and Standards (e.g., Food Grade):

- Consideration: If used in sensitive applications such as food, beverages, pharmaceuticals, or drinking water, does it need to comply with relevant hygiene and safety standards like FDA, NSF, REACH, RoHS?

- Recommendation: Always choose hoses with the appropriate certification markings.

- External Environment:

- Consideration: Will the hose be exposed to sunlight, ozone, extreme weather, or physical abrasion?

- Recommendation: Select hoses with good weather resistance and UV resistance.

Conclusion

By taking a closer look at PVC hose, we clearly realize that it plays a vital and versatile role in modern society. From its unique polyvinyl chloride material properties to its precise manufacturing process, to its wide variety and wide range of applications, PVC hose has become an ideal choice for conveying a variety of fluids and media due to its flexibility, durability, chemical compatibility and cost-effectiveness.