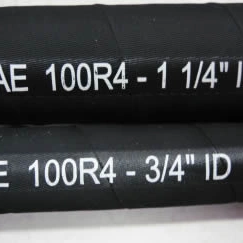

R4 Hydraulic Hose

The R4 hydraulic hose is specifically designed for low-pressure suction and return line applications, distinguishing itself with a robust, often wire-reinforced, construction that prevents collapse under vacuum. Conforming to SAE 100R4 standards, this hose is essential for transferring large volumes of hydraulic fluid, oil, and water-based solutions, particularly where the fluid is drawn from a reservoir or needs to return with minimal restriction. Widely utilized in industrial machinery, agricultural equipment, and mobile hydraulics, the R4 hydraulic hose provides a reliable and collapse-resistant solution, ensuring consistent flow and efficient operation in critical fluid management systems.

Get Your Desired R4 Hydraulic Hose

R4 hydraulic hoses include a range of specialized types, each engineered to meet specific needs while meeting the core standard of SAE 100R4 low pressure suction return lines. This variety ensures that whether your application involves extreme temperatures, unique fluid compatibility requirements, or superior external protection, there is an R4 hydraulic hose that precisely meets these challenges.

All R4 Hydraulic Hoses

Standard R4 Hydraulic Hose for General Suction

The standard R4 hydraulic hose is the fundamental choice for general low-pressure suction and return line applications. It typically features an oil-resistant synthetic rubber inner tube, reinforced with multiple textile plies and a helical wire to prevent collapse under vacuum. The outer cover is usually a weather and abrasion-resistant synthetic rubber. This robust construction makes it ideal for transferring petroleum-based hydraulic fluids, lubricating oils, and water-based solutions, ensuring reliable, uninterrupted flow in various industrial, agricultural, and mobile hydraulic systems where flexibility and anti-collapse properties are essential.

High-Temperature R4 Hydraulic Hose

For applications where hydraulic systems operate in environments with elevated temperatures, the high-temperature R4 hydraulic hose is specifically engineered. This variant features advanced materials in its inner tube and outer cover that resist degradation from continuous exposure to heat, exceeding the standard operating temperature range. It’s crucial for machinery operating near hot engine components, in high-temperature industrial processes, or in warmer climates. Choosing a high-temperature R4 hydraulic hose ensures system integrity and fluid stability, preventing premature hose failure and maintaining operational safety even in demanding thermal conditions.

Oil and Chemical-Resistant R4 Hydraulic Hose

When hydraulic systems handle a variety of aggressive fluids beyond standard petroleum-based oils, the oil and chemical-resistant R4 hydraulic hose is essential. Its inner tube is constructed from materials specifically chosen for their compatibility with a broader range of hydraulic fluids, synthetic oils, and certain industrial chemicals. This prevents material degradation, swelling, or breakdown that could lead to system contamination or hose failure. Critical for chemical processing, specialized manufacturing, or areas using non-standard fluids, this R4 hydraulic hose ensures fluid integrity and hose longevity, protecting the entire hydraulic system.

Custom Non-Conductive R4 Hydraulic Hose

For hydraulic systems operating in proximity to electrical hazards, the non-conductive R4 hydraulic hose is a vital safety component. Its outer cover is made from a non-conductive material, providing an insulating barrier that protects personnel from electrical shock in the event of accidental contact with live wires or electrical sources. Commonly used on utility vehicles, aerial lifts, and other equipment where operators work near power lines, the non-conductive R4 hydraulic hose meets specific safety standards, ensuring that the hydraulic fluid path does not become an electrical conductor, thereby enhancing workplace safety.

Flexible R4 Hydraulic Hose

The flexible R4 hydraulic hose prioritizes ease of installation and routing, especially in applications with tight bends or limited space. While all R4 hoses offer some flexibility due to their textile plies and often helix wire, certain variants are designed for even greater pliability. This enhanced flexibility reduces installation time, minimizes stress on fittings, and allows for more intricate system designs. An R4 hydraulic hose with superior flexibility is crucial for efficient assembly and reliable performance in dynamically moving hydraulic systems.

Custom R4 Hydraulic Hose Wholesale

Construction and Design

The R4 hydraulic hose is uniquely constructed for suction and return line duties. It features an oil-resistant inner tube, often reinforced with multiple textile plies and a helix wire to prevent collapse under vacuum. An abrasion-resistant outer cover completes the design. This robust build ensures large volume fluid transfer without kinking or collapsing, critical for system efficiency.

Application Versatility

The R4 hydraulic hose boasts broad application versatility across various industries. It’s commonly used in industrial machinery for hydraulic return lines, in agricultural equipment for fuel transfer or suction from tanks, and in mobile hydraulic systems. Its ability to handle large volumes of fluid at low pressures makes it ideal for a wide array of non-pressure-critical fluid management tasks.

Suction and Return Line Performance

Designed specifically for suction and return line performance, the R4 hydraulic hose excels at handling low pressures and negative pressure (vacuum). Its internal reinforcement prevents the hose from collapsing when fluid is drawn through it or when a vacuum forms during fluid return. This ensures uninterrupted flow, preventing cavitation and maintaining hydraulic system integrity.

Durability and Collapse Resistance of R4 Hydraulic Hose

A primary benefit of R4 hydraulic hose is its exceptional durability and collapse resistance. The internal wire helix and textile reinforcement layers prevent the hose from kinking or collapsing under vacuum conditions. This robust construction ensures long-term reliability and minimizes the risk of system downtime caused by flow restrictions, even in demanding environments.

What is R4 hydraulic hose primarily used for?

R4 hydraulic hose is primarily used for low-pressure suction and return lines in hydraulic systems. Its design prevents collapse under vacuum conditions, making it ideal for drawing fluid from reservoirs or returning it with minimal flow restriction.

Common applications include reservoir lines, fuel lines, and general fluid transfer where the hose needs to maintain its shape under negative pressure or low positive pressure.

What does "R4" signify in hydraulic hose standards?

“R4” signifies that the hydraulic hose conforms to the SAE 100R4 standard. This specification denotes a hose designed for low-pressure suction and return applications, often featuring textile plies and a wire helix reinforcement to resist collapse under vacuum.

Adhering to the SAE 100R4 standard ensures the hose meets industry benchmarks for performance and safety in non-pressure-critical fluid management.

What types of fluids can R4 hydraulic hose convey?

R4 hydraulic hose is typically designed to convey petroleum-based hydraulic fluids, lubricating oils, and water-based solutions. Its inner tube material is selected for compatibility with these common low-pressure mediums.

Always consult the specific manufacturer’s data sheet for full fluid compatibility, especially if you plan to use specialized or synthetic fluids. This ensures the hose performs optimally and safely without degradation.

How do I choose the right hydraulic hose for my application?

Choosing the right hydraulic hose involves considering several critical factors, often remembered by the acronym STAMPED: Size (inner diameter, length), Temperature (of fluid and environment), Application (what it’s used for), Media (type of fluid), Pressure (working and burst), Ends (fittings), and Delivery (volume/flow rate). Properly evaluating these aspects ensures the hose meets the system’s demands safely and efficiently.

Failing to select a hose that matches these specifications can lead to premature wear, leaks, or even catastrophic failure. Consulting manufacturer specifications and industry standards like SAE is essential for making

What are the common signs of hydraulic hose failure?

Common signs of hydraulic hose failure include visible external damage like abrasion, cuts, cracks, or blistering on the outer cover. Other indicators are a leaking hose (even small drips), which suggests the hose’s integrity is compromised, or a hardened, stiff, or unusually soft/spongy hose, indicating material degradation due to heat or chemical exposure.

Internal damage, though less visible, can manifest as a loss of hydraulic system power or erratic operation due to blockages or internal tube collapse. Regularly inspecting your hydraulic hoses for these signs can prevent unexpected downtime, costly repairs, and potential safety hazards.

Quote R4 Hydraulic Hose Wholesale

Is your project held back by unsuitable hydraulic hoses? Don’t compromise on performance or struggle with ill-fitting components. We offer 3/16 hydraulic hose wholesale, custom-tailored to your exact specifications. Get precise lengths, ideal pressure ratings, and the perfect fittings for seamless integration, ensuring your systems operate with maximum efficiency and reliability, every time.