Rubber Mining Hose

Rubber mining hoses are designed for demanding mining environments where abrasion, impact, and high pressure are constant challenges. We offer durable rubber mining hoses with reinforced structures, excellent wear resistance, and stable performance for slurry transfer, water delivery, and dewatering applications in surface and underground mining operations.

Get Your Desired Rubber Mining Hose

Get your desired rubber mining hose tailored to your specific application and working conditions. We provide flexible customization in size, pressure rating, rubber compounds, and reinforcement structures. Our rubber mining hoses are built to handle abrasion, heavy loads, and harsh environments while ensuring reliable, long-term performance in mining operations.

All Rubber Mining Hoses

mining hydraulic hoses

Mining hydraulic hoses are built to handle high pressure, heavy loads, and harsh operating conditions. We offer mining hydraulic hoses with robust reinforcement, oil-resistant rubber compounds, and reliable flexibility. They are suitable for underground and surface mining equipment, ensuring stable fluid transfer, reduced downtime, and long service life.

mining rubber hoses

Mining rubber hoses are built to handle abrasive materials, high pressure, and harsh working conditions in mining operations. We offer a full range of mining rubber hoses with strong reinforcement, excellent wear resistance, and flexible customization. Our solutions support slurry transfer, water supply, and dewatering in surface and underground mines.

four wire spiral hydraulic hose for mining

Four wire spiral hydraulic hoses for mining are built to withstand extreme pressure, heavy vibration, and harsh working conditions. We offer robust hoses with high-tensile steel wire reinforcement, excellent impulse resistance, and strong abrasion protection, ensuring stable fluid transfer and long service life in demanding underground and surface mining applications.

steel reinforced mining hydraulic hoses

Steel reinforced mining hydraulic hoses are built for extreme pressure and harsh mining conditions. We offer hoses with high-strength steel wire reinforcement, excellent impulse resistance, and strong abrasion protection. Designed for hydraulic fluid transfer, they ensure stable performance, safety, and long service life in underground and surface mining equipment.

Super flexible rubber mining hose

Super flexible rubber mining hoses designed for ease of handling in tough mining conditions. We offer hoses with reinforced structures, durable rubber compounds, and excellent abrasion resistance. Ideal for slurry transfer, water delivery, and dewatering, our hoses combine flexibility, strength, and reliability to meet the demanding needs of mining operations.

rubber suction mining hoses

Rubber suction mining hoses designed for efficient fluid transfer in demanding mining operations. We offer hoses with reinforced structures, excellent flexibility, and abrasion-resistant rubber compounds. Ideal for slurry, water, and dewatering applications, our rubber suction mining hoses ensure reliable suction performance, durability, and ease of handling in harsh mining environments.

steel wire braided rubber mining hoses

Steel wire braided rubber mining hoses provide excellent strength and flexibility for harsh mining conditions. We offer durable, high-pressure hoses resistant to abrasion, heat, and chemicals. Ideal for transporting water, slurry, or air, our hoses ensure reliable performance, safety, and long service life in demanding mining operations worldwide.

Custom Rubber Mining Hose Wholesale

Rubber compound and material

We select and customize rubber compounds to match the specific mining environment. Whether you need high abrasion resistance for slurry, chemical resistance for corrosive fluids, or extreme temperature tolerance, we adjust the formulation to ensure long-lasting performance and stable operation under harsh conditions.

Reinforcement structure

We design reinforcement layers using textile braids, steel wire, or hybrid structures to improve strength, kink resistance, and durability. By tailoring reinforcement density and arrangement, we provide hoses that maintain shape and reliability, even under constant movement, abrasion, and high-pressure mining applications.

Hose size and pressure rating

We customize the inner diameter, wall thickness, and overall length to suit your flow and pressure requirements. By specifying pressure ratings, burst strength, and flexibility, we ensure the hose handles mining operations safely while maintaining optimal performance, even under heavy loads or high-pressure slurry transfer.

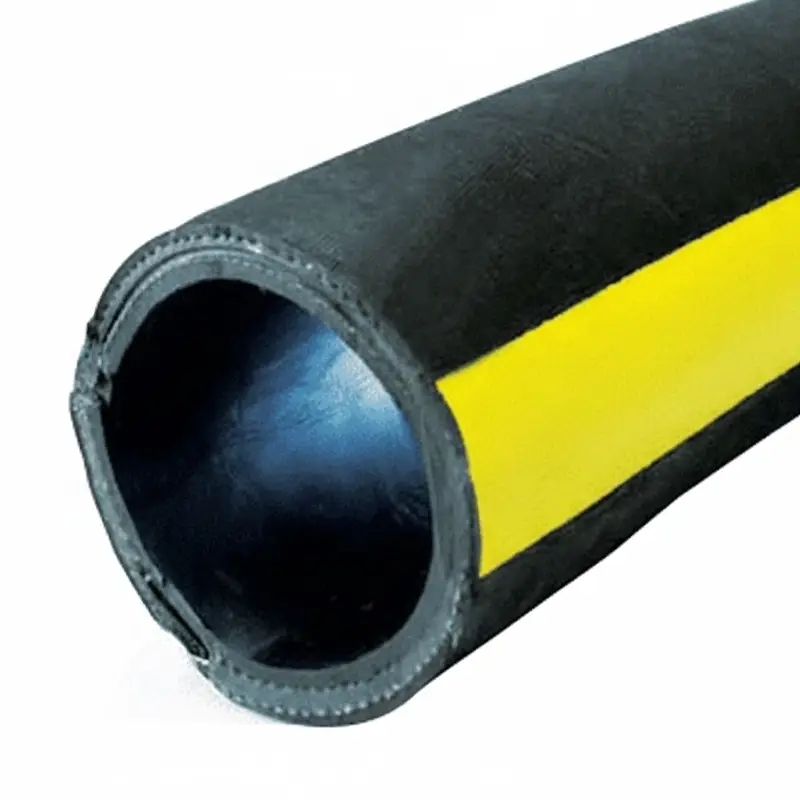

Appearance and identification

We offer customization in hose color, stripe patterns, and surface finish for easy identification in complex mining operations. We can also add branding, logos, or labeling to meet safety and operational standards, making your hoses easy to distinguish, manage, and maintain on-site.

Quote Rubber Mining Hose Wholesale

Is your project held back by unsuitable hydraulic hoses? Don’t compromise on performance or struggle with ill-fitting components. We offer 3/16 hydraulic hose wholesale, custom-tailored to your exact specifications. Get precise lengths, ideal pressure ratings, and the perfect fittings for seamless integration, ensuring your systems operate with maximum efficiency and reliability, every time.