When we talk about the essential role of fire sleeves in protecting critical components from extreme heat and fire, it’s easy to overlook the sophisticated process involved in their creation. These aren’t just simple fabric tubes; they are engineered solutions.

As manufacturers, we know that producing a fire sleeve that can reliably withstand molten splash, direct flame, and continuous high temperatures requires meticulous attention to detail, specialized materials, and precise manufacturing techniques. Let’s pull back the curtain and explore the fascinating journey of how to make fire sleeves, from raw materials to the finished product you trust for safety and durability.

What Goes Into a Fire Sleeve?

Before we delve into the manufacturing steps, it’s crucial to understand the fundamental materials that give fire sleeves their incredible protective properties. The quality and composition of these raw materials are paramount to the final product’s performance and safety.

A high-performance fire sleeve primarily consists of two key components:

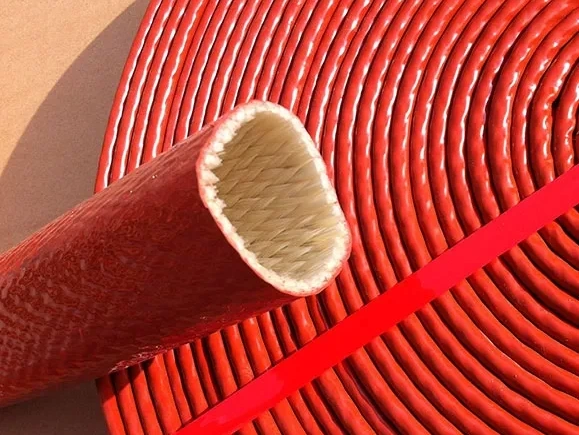

- The Insulating Core Material: This forms the structural and thermal barrier. The most common choices are:

- Braided Fiberglass: Known for its excellent thermal insulation, high tensile strength, and good resistance to many chemicals. It’s cost-effective and widely used.

- Braided Basalt Fiber: Offering superior high-temperature resistance compared to fiberglass, basalt fiber is chosen for more extreme applications. It also boasts good chemical and abrasion resistance.

- Other high-temperature synthetic fibers: For specific niche applications, other proprietary fibers might be used.

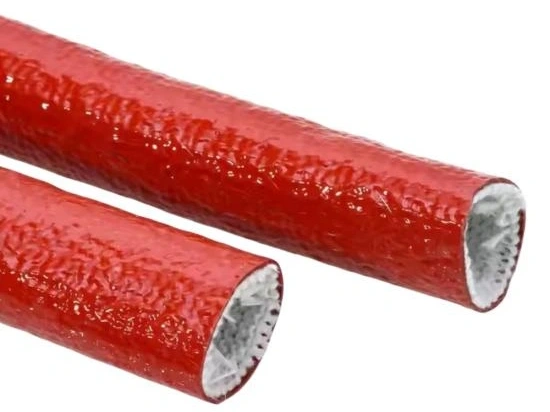

- The Outer Protective Coating: This is the distinctive, often colored, layer that provides additional thermal protection, flame resistance, and protection against fluids and abrasion.

- Silicone Rubber: This is the industry standard. It’s specifically formulated to be highly resistant to extreme temperatures, direct flame, molten splash, oils, hydraulic fluids, and various chemicals. Its flexibility and durability are also key attributes.

The synergy between these two layers is what makes a fire sleeve truly effective. The inner braid provides the bulk of the thermal insulation, while the outer silicone coating acts as a robust shield against direct impingement, fluids, and abrasion.

What is the Function of a Fire Sleeve?

The primary function of a fire sleeve is to provide critical thermal protection for hoses, cables, and wires exposed to high temperatures, open flames, or molten splash environments.

- Insulating Against High Heat: Composed of an inner fiberglass or basalt fiber layer, it effectively blocks external heat, maintaining a stable temperature for internal components.

- Flame and Molten Splash Resistance: The outer silicone rubber coating boasts excellent flame retardancy, resisting direct flame and molten metal splash, thereby preventing fire spread.

- Extending Component Lifespan: It protects hoses and wires from thermal degradation, reducing issues like cracking and hardening, which in turn extends their service life and lowers maintenance costs.

- Enhancing Safety: It prevents flammable fluid lines from rupturing and igniting due to overheating, and stops electrical wires from short-circuiting and causing fires, significantly boosting the safety of the operating environment.

In essence, a fire sleeve acts as a crucial protective barrier, ensuring the continuous and safe operation of equipment even under extremely high-temperature conditions.

Step-by-Step: How to Make Fire Sleeves

Producing a high-quality fire sleeve is a multi-stage process that requires specialized machinery and strict quality control at each phase. We follow a carefully orchestrated sequence to ensure every sleeve meets our rigorous performance standards.

Step 1: Preparing the Inner Braid – The Insulating Foundation

The first critical step involves creating the insulating core. This is where the magic of thermal resistance truly begins.

- Fiber Selection and Preparation:

- We start by selecting high-grade fiberglass or basalt fiber rovings (bundles of fibers). The choice depends on the desired temperature rating and application.

- These rovings are loaded onto large spools, ready for the braiding machine.

- Braiding the Tubular Core:

- The spools of fiber are fed into a specialized braiding machine. This machine intricately weaves the fibers into a seamless, flexible, tubular braid.

- The braiding pattern, tension, and density are precisely controlled to achieve the desired wall thickness, thermal insulation properties, and flexibility of the final sleeve. This is a critical step, as inconsistent braiding can lead to weak spots.

- The braided tubing is then collected onto large reels.

Step 2: Applying the Silicone Coating – The Protective Armor

Once the inner braid is formed, the next crucial step is to apply the robust silicone outer coating. This is what gives the fire sleeve its signature protection against flames, fluids, and high temperatures.

- Silicone Compounding:

- High-temperature resistant silicone rubber is carefully compounded. This involves mixing various silicone polymers with specific additives, color pigments (typically iron oxide for red, carbon black for black), and vulcanizing agents. The precise formulation is key to achieving the desired heat resistance, flame retardancy, flexibility, and chemical resistance.

- Extrusion or Coating Process:

- The braided fiberglass or basalt tube is then fed through a specialized coating line.

- In an extrusion process, the silicone compound is extruded onto the braided core, forming a uniform, continuous outer layer. The thickness of this layer is meticulously controlled.

- Alternatively, some manufacturers might use a dip coating process, where the braid is repeatedly dipped into liquid silicone, with drying and curing steps between dips to build up the desired thickness.

- Vulcanization (Curing):

- After the silicone is applied, the sleeve enters a curing oven or is passed through a vulcanization chamber. Heat is applied to initiate a chemical reaction that cross-links the silicone molecules, transforming the soft, uncured silicone into a tough, durable, and highly resilient rubber. This process locks in the heat resistance and physical properties.

- Precise temperature and time control during vulcanization are critical to ensure full curing without degrading the underlying braid.

Step 3: Finishing and Quality Control – Ensuring Performance

Once the sleeve is cured, it undergoes final processing and stringent quality checks to ensure it meets all performance specifications.

- Cooling and Coiling:

- The cured sleeve is cooled down to ambient temperature and then carefully coiled onto large drums or spools, ready for further processing or packaging.

- Cutting to Length:

- The continuous sleeve is cut into specified lengths, as per customer orders or standard product dimensions. This often involves automated cutting machines for precision.

- End Treatment (Optional):

- For some applications, the ends of the sleeves might be treated to prevent fraying of the inner braid or to provide a cleaner finish. This could involve heat-shrinking end caps or specialized coatings.

- Quality Assurance and Testing:

- This is a non-negotiable final step. Every batch of fire sleeves undergoes rigorous testing to verify its performance characteristics. This includes:

- Visual Inspection: Checking for defects, inconsistencies in coating, or damage.

- Dimensional Checks: Verifying internal and external diameters, wall thickness, and length.

- Temperature Resistance Testing: Subjecting samples to high temperatures, direct flame, and molten splash tests to confirm their rated performance. This often involves industry-standard tests like the AS1072 fire test for aviation hoses.

- Flexibility and Abrasion Resistance Tests: Ensuring the sleeve maintains its flexibility and can withstand mechanical wear.

- Fluid Resistance Testing: Checking resistance to common industrial fluids like oils and hydraulic fluid.

- Dielectric Strength Testing (for electrical sleeves): Ensuring electrical insulation properties.

- Only sleeves that pass all these stringent tests are approved for packaging and shipment.

- This is a non-negotiable final step. Every batch of fire sleeves undergoes rigorous testing to verify its performance characteristics. This includes:

What is the Heat Rating of a Fire Sleeve?

The heat rating of a fire sleeve is multi-faceted, indicating its ability to withstand various thermal conditions. Typically, a high-quality fire sleeve will have three key temperature ratings:

- Continuous Operating Temperature: This is the maximum temperature the sleeve can endure for prolonged periods without degradation. Common ratings are around 260°C (500°F).

- Intermittent Exposure Temperature: This specifies the higher temperature the sleeve can tolerate for short durations, usually a few minutes. This can often reach 1093°C (2000°F) or even 1200°C (2200°F).

- Molten Splash Protection: This indicates the extremely high temperature of molten metal or direct flame impingement the sleeve can repel for very brief periods, often around 1650°C (3000°F).

These ratings ensure the sleeve provides reliable protection in diverse high-temperature scenarios, from engine bay heat to sudden molten metal splashes.

Critical Factors in Making a Superior Fire Sleeve

The manufacturing process is complex, and several factors are paramount in distinguishing a high-quality fire sleeve from an inferior one. These are the aspects we focus on to ensure our products deliver maximum protection.

| Factor | Why It Matters |

| Raw Material Purity | Using high-grade, virgin fiberglass/basalt and specifically formulated, high-temperature silicone is fundamental. Impurities or low-quality materials compromise heat resistance and durability. |

| Precise Braiding Control | The density and uniformity of the inner braid directly impact thermal insulation. Loose or inconsistent braiding creates weak spots. |

| Uniform Silicone Application | An even, consistent thickness of the silicone coating is crucial for uniform flame, molten splash, and fluid protection. Thin spots will be points of failure. |

| Optimal Vulcanization | Correct curing temperature and time ensure the silicone reaches its full strength and heat resistance. Under-curing leaves it soft; over-curing can make it brittle. |

| Rigorous Quality Control | Continuous testing throughout the process and comprehensive final product testing are essential to guarantee every sleeve meets stated performance and safety standards. |

| Adherence to Standards | Manufacturing to recognized industry standards (e.g., ISO, SAE, AS) ensures product reliability and interoperability. |

Conclusion

In summary, the manufacturing journey of fire sleeving is a testament to advanced material science and precision engineering. From carefully selected high-temperature resistant fibers and custom-compounded silicones to precise braiding, coatings, and stringent quality control, each step is critical to creating a product that can reliably withstand some of the most destructive forces in industrial and automotive environments.

Manufacturing fire sleeving is more than just about producing a product; it’s about providing our customers with the necessary safety and continuity of their operations. When you see a fire sleeve, remember that behind its simple exterior lies a complex and carefully engineered solution designed to ensure your operations run smoothly and safely, even in the most demanding conditions.

What are the specific performance requirements of fire sleeving in your industry? We’re ready to discuss how we can leverage our manufacturing expertise to meet your unique needs.