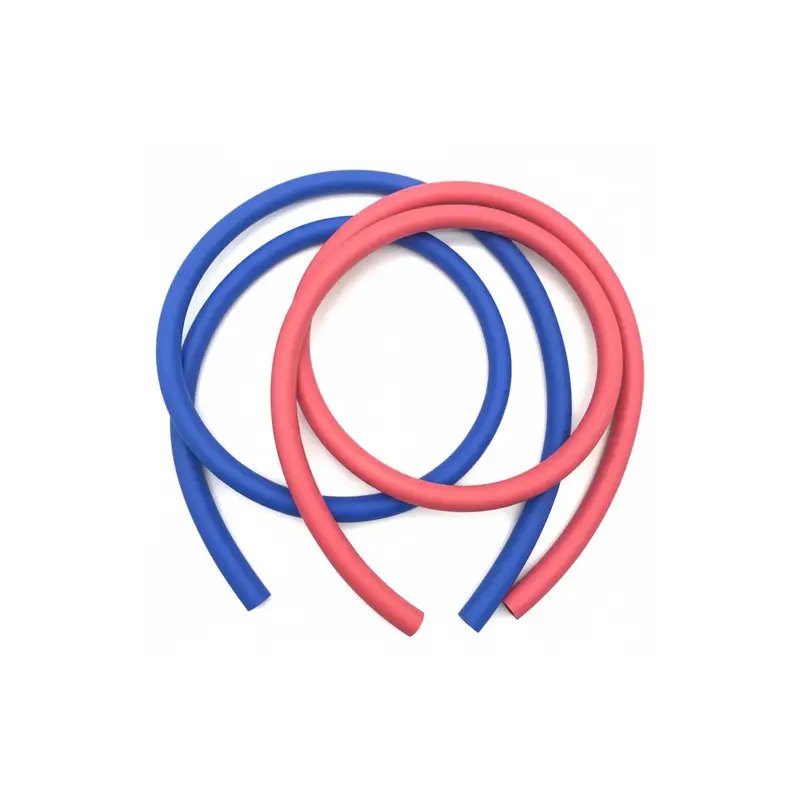

NBR Rubber Hose

Suffering from frequent hose failures due to incompatible materials? Our NBR rubber hoses provide the robust solution you need. Engineered for excellent resistance to petroleum-based fluids, oils, and fuels, they significantly extend service life and ensure reliable performance in demanding industrial applications, minimizing downtime and replacement costs.

Get Your Desired NBR Rubber Hose

Tired of struggling with generic hoses that fail under pressure? Our NBR rubber hoses are engineered to meet your exact specifications, delivering superior resistance to oils and fuels. Avoid costly downtime and unreliable performance. Partner with us to get the precise NBR hose solution that ensures maximum efficiency and longevity for your critical operations.

All NBR Rubber Hoses

NBR Fuel Hose

Struggling with fuel hoses that crack or degrade quickly? Our NBR fuel hoses are meticulously manufactured to provide exceptional resistance to petroleum-based fuels, oils, and diesel. Say goodbye to frequent replacements and hazardous leaks. We provide reliable, high-performance NBR fuel hoses, ensuring safety and efficiency for your vital fuel transfer applications.

NBR CR hose

Constantly battling hoses that crack or degrade from weather exposure and oil? Our NBR/CR blend hoses offer a superior solution. We manufacture hoses that combine the excellent oil and fuel resistance of NBR with the enhanced weatherability and ozone resistance of CR (Chloroprene Rubber). This synergistic blend ensures your hoses withstand harsh environments, resist aging, and deliver long-lasting, reliable performance, reducing costly replacements and maintenance.

NBR CSM hose

Worried about hoses degrading rapidly in demanding conditions? Our NBR/CSM hoses combine robust oil and fuel resistance with exceptional weatherability. We manufacture and supply premium NBR/CSM hoses engineered to withstand ozone, UV, and a wide range of chemicals, ensuring extended service life and minimizing costly replacements for your critical applications. Secure long-term reliability for your operations.

NBR PVC hose

Feeling frustrated by hoses that stiffen in the cold or can’t handle oil? We manufacture NBR PVC hoses specifically designed to overcome these challenges. Our advanced blend offers exceptional flexibility even in sub-zero temperatures, combined with excellent oil and abrasion resistance. Get the reliable performance your operations demand, ensuring continuous flow and reduced maintenance.

NBR layflat hose

Struggling with bulky, rigid hoses for your fluid transfer needs? Our NBR layflat hoses are the lightweight, flexible solution you’ve been searching for. Avoid inefficient operations and difficult storage. We manufacture high-quality NBR layflat hoses that offer superior resistance to oil and chemicals, ensuring easy deployment, compact storage, and reliable, high-volume flow for your demanding applications.

NBR CSM hose

We offer high-performance NBR/CSM rubber hoses, a specialized blend that combines the excellent oil and fuel resistance of Nitrile Rubber (NBR) with the superior heat, ozone, and weathering resistance of Chlorosulfonated Polyethylene (CSM). This composite material is ideal for critical automotive and industrial applications requiring protection against both aggressive oils and harsh outdoor environments.

NBR flexible hose

We offer highly flexible NBR (Nitrile Butadiene Rubber) hoses, renowned for their excellent resistance to petroleum-based fluids. Our custom NBR hoses are ideal for fluid transfer in oil, fuel, and hydraulic systems, maintaining optimal performance and sealing integrity under continuous exposure to oils and greases. We ensure a reliable fit for demanding industrial and automotive applications.

NBR coolant hose

We offer specialized NBR coolant rubber hoses designed for applications where oil exposure and coolant transfer overlap. While EPDM is typical for pure glycol coolant, our NBR construction provides essential resistance to oil mist and splashes common in engine bays. These hoses ensure reliable performance in environments demanding both oil and water compatibility, offering durable service where standard hoses would quickly fail.

NBR fuel hoses

We offer premium NBR (Nitrile Butadiene Rubber) fuel hoses, specifically engineered for exceptional resistance to gasoline, diesel, and various petroleum-based oils. Our hoses maintain integrity against hydrocarbon degradation and swelling, ensuring a leak-free, reliable performance in vehicle fuel systems and industrial oil transfer applications. We custom-manufacture them for your exact specifications and high-volume needs.

NBR FKM rubber hoses

We offer a comprehensive range of high-performance NBR and FKM rubber hoses. Our NBR (Nitrile) hoses are ideal for oil and fuel systems, while our premium FKM (Fluorocarbon/Viton) hoses provide the highest resistance to aggressive chemicals, extreme heat, and concentrated acids, ensuring maximum reliability.

Custom NBR Rubber Hose Wholesale

Material Compound Optimization

Customizing the NBR rubber compound is crucial. We can adjust the acrylonitrile (ACN) content to fine-tune resistance to specific oils, fuels, and chemicals. This also impacts flexibility and temperature range. For instance, higher ACN offers better oil resistance but less low-temperature flexibility, allowing us to meet precise application requirements for durability and performance.

Inner Diameter (ID) and Outer Diameter (OD)

Precise customization of both the inner and outer diameters is vital for optimal flow and fitting compatibility. We can produce hoses with a wide range of IDs to match flow rate requirements and ODs to ensure seamless integration with existing connectors, clamps, and routing constraints. This tailored approach prevents leaks and ensures efficient system operation.

Reinforcement Type and Pressure Rating

The choice of reinforcement greatly influences the hose’s pressure capability and flexibility. Options include textile braids (e.g., polyester, aramid), spiral wire, or multiple plies. We can customize the type and number of reinforcement layers to achieve the exact working pressure, burst pressure, and desired flexibility, ensuring the hose can safely handle your system’s demands.

Outer Cover Material and Abrasion Resistance

The outer cover material can be customized to provide specific environmental protection. While NBR offers good general resistance, we can incorporate compounds like PVC/NBR blends or specialized synthetic rubbers to enhance resistance against abrasion, ozone, UV radiation, and harsh weather conditions. This tailored cover extends the hose’s lifespan, especially in challenging outdoor or industrial environments, reducing wear and tear from external factors.

what Is NBR Rubber?

NBR rubber, also known as Nitrile Butadiene Rubber or Buna-N, is a synthetic rubber copolymer derived from acrylonitrile and butadiene.

It is widely recognized for its excellent resistance to petroleum-based oils, fuels, and many chemicals, making it a staple in industries where fluid compatibility is crucial. The proportion of acrylonitrile in the polymer can be varied during manufacturing, which directly influences the rubber’s properties; a higher acrylonitrile content generally leads to better oil and fuel resistance but may reduce flexibility at lower temperatures.

This versatility allows NBR to be tailored for a wide range of applications, including seals, O-rings, gaskets, and, importantly, hoses for oil and fuel transfer systems.

density of NBR rubber

The density of NBR rubber is not a single fixed value but rather a range that can vary depending on its specific formulation and compounding. Generally, the density of NBR rubber typically falls between 1.00 and 1.30 g/cm³.

This range is influenced by factors such as the acrylonitrile (ACN) content, which affects oil resistance and flexibility, as well as the types and amounts of fillers, plasticizers, and curing agents added during the compounding process.

For instance, adding fillers like carbon black or silica will increase the density and often improve mechanical properties like strength and durability. Conversely, incorporating plasticizers tends to reduce density while enhancing flexibility.

Therefore, the specific density of an NBR compound is tailored to meet the performance requirements of its intended application, ranging from lighter, more flexible grades for seals and gaskets to denser compounds for heavy-duty industrial hoses and vibration dampers.

NBR rubber chemical compatibility

NBR rubber is widely valued for its excellent chemical compatibility with a range of substances, making it suitable for numerous industrial applications. Its resistance primarily stems from its acrylonitrile content; higher ACN levels generally lead to better resistance.

Oils and Fuels: NBR offers outstanding resistance to petroleum-based oils, diesel fuel, gasoline, hydraulic fluids, and greases. This makes it a preferred material for fuel lines, oil seals, and hydraulic hoses.

Water and Alcohols: NBR typically exhibits good resistance to water, including hot water (though not steam), and various alcohols. This broad compatibility extends its use in many fluid transfer and sealing applications.

Diluted Acids and Bases: NBR can withstand exposure to many dilute acids and bases. However, its resistance diminishes significantly with strong oxidizing acids or concentrated alkaline solutions, which can cause swelling or degradation.

Limited Aromatic and Chlorinated Solvents: NBR has poor resistance to aromatic hydrocarbons like benzene and toluene, and chlorinated solvents such as trichloroethylene. Exposure to these can lead to considerable swelling and material breakdown.

Poor Ozone and UV Resistance: A significant limitation of NBR is its poor resistance to ozone, UV radiation, and general weathering. For outdoor applications or environments with high ozone levels, NBR typically requires protective additives or coatings, or an alternative material should be considered.

NBR rubber chemical resistance

NBR rubber, or Nitrile Butadiene Rubber, is highly valued for its chemical resistance, which makes it a preferred choice in applications involving various fluids. Its resistance profile is primarily determined by its acrylonitrile (ACN) content; generally, a higher ACN percentage provides better resistance to oils and fuels, though it can slightly reduce flexibility in very cold temperatures.

Here’s an overview of NBR’s chemical resistance:

Petroleum-Based Oils and Fuels: NBR exhibits excellent resistance to a wide array of petroleum-based products including crude oil, gasoline, diesel fuel, hydraulic fluids, and greases. This makes it ideal for components in automotive fuel systems, oil seals, and industrial hydraulic hoses.

Water and Alcohols: NBR generally holds up well against water and various types of alcohols. This broad compatibility allows its use in many sealing and fluid transfer applications where exposure to these common liquids occurs.

Diluted Acids and Bases: NBR offers good resistance to many dilute acids and bases. However, its performance degrades significantly when exposed to strong oxidizing acids or highly concentrated alkaline solutions, which can lead to swelling, softening, or breakdown of the material.

Aromatic Hydrocarbons and Polar Solvents: NBR has poor resistance to aromatic hydrocarbons like benzene, toluene, and xylene, as well as polar solvents such as acetone, MEK (methyl ethyl ketone), and chlorinated solvents like trichloroethylene. Contact with these substances can cause considerable swelling, softening, and rapid degradation.

Ozone and UV Radiation: A notable limitation of NBR rubber is its poor resistance to ozone, ultraviolet (UV) radiation, and general weathering. Prolonged exposure to outdoor elements or environments with high ozone concentrations can lead to surface cracking and material degradation, making it less suitable for unprotected outdoor applications unless specially compounded with protective additives.

what is NBR rubber used for?

NBR rubber’s unique combination of oil, fuel, and chemical resistance, along with good mechanical properties, makes it highly versatile across numerous industries. It’s particularly favored in applications where contact with hydrocarbons is prevalent and a reliable seal or flexible conduit is required. Its ability to maintain integrity in such environments prevents leaks, system failures, and ensures long-term performance.

Common applications for NBR rubber include:

- Automotive Industry: NBR is extensively used for fuel and oil handling hoses, O-rings, gaskets, oil seals, and diaphragms within engines, fuel systems, and hydraulic systems. Its resistance to petroleum-based fluids is critical here.

- Oil and Gas: In the oil and gas sector, NBR finds use in seals for drilling equipment, hoses for transferring crude oil and refined fuels, and various components exposed to petroleum products. Its durability in harsh conditions is essential.

- Hydraulic and Pneumatic Systems: Due to its excellent resistance to hydraulic fluids and good compression set, NBR is a common material for seals, O-rings, and hoses in hydraulic and pneumatic machinery, ensuring leak-free operation.

- Protective Gloves: Disposable nitrile gloves are widely used in medical, laboratory, and food service industries as a latex-free alternative. They offer good puncture resistance and barrier protection against chemicals and biological agents.

- General Industrial Applications: NBR is found in a wide array of industrial products such as conveyor belts, printer’s rollers, footwear soles (especially for oil-resistant work boots), and various molded and extruded components where oil or chemical resistance is required.

NBR rubber Hose Benefits

NBR rubber hoses are a popular choice across many industries due to a combination of beneficial properties, offering a balance of performance and cost-effectiveness. Their unique chemical composition, particularly the presence of acrylonitrile, grants them specific advantages that make them suitable for diverse applications.

Here are some key benefits of NBR rubber hoses:

- Excellent Oil and Fuel Resistance: NBR hoses are highly resistant to degradation from petroleum-based oils, fuels (including gasoline and diesel), hydraulic fluids, and greases. This is their most significant advantage, preventing swelling, softening, and deterioration that can lead to leaks and system failures.

- Good Abrasion and Tear Resistance: NBR rubber provides good resistance to abrasion, cuts, and tears, which contributes to the hose’s durability and extended service life in demanding industrial environments where hoses might be subjected to rubbing or physical stress.

- Wide Temperature Operating Range: NBR hoses can operate effectively across a broad temperature spectrum, typically from around -40°C to +100°C (with some specialized grades reaching higher). This versatility allows them to function reliably in various climatic conditions and industrial processes.

- Good Flexibility and Elasticity: NBR hoses offer a good balance of flexibility and elasticity, making them relatively easy to route and install in complex systems. This property also helps them withstand bending and continuous movement without cracking or kinking, ensuring consistent flow.

- Cost-Effectiveness: Compared to higher-performance elastomers like FKM or silicone, NBR rubber hoses are generally more economical. This makes them a cost-effective solution for a wide range of applications where their specific resistance properties are sufficient, offering a good balance between performance and budget.

Quote NBR Rubber Hose Wholesale

Struggling with inconsistent hose quality and inflated prices? Secure your bulk NBR rubber hose needs with us. Avoid unreliable supply chains and budget overruns. We provide wholesale NBR hoses manufactured to stringent standards, ensuring superior oil and fuel resistance and long-lasting performance for your industrial and commercial demands. Contact us for a competitive quote today.