When specifying hydraulic hoses for extreme environments, material selection is paramount. You need a rubber that can withstand aggressive chemicals, high temperatures, and constant pressure without compromising performance or safety. Choosing the wrong material can lead to premature failure, leaks, and costly downtime.

This often leads to a crucial decision: FKM or Viton? Both are renowned fluorocarbon rubbers, but understanding their subtle yet significant differences is key to ensuring your hydraulic hoses deliver optimal, long-lasting reliability in the toughest applications.

What is FKM?

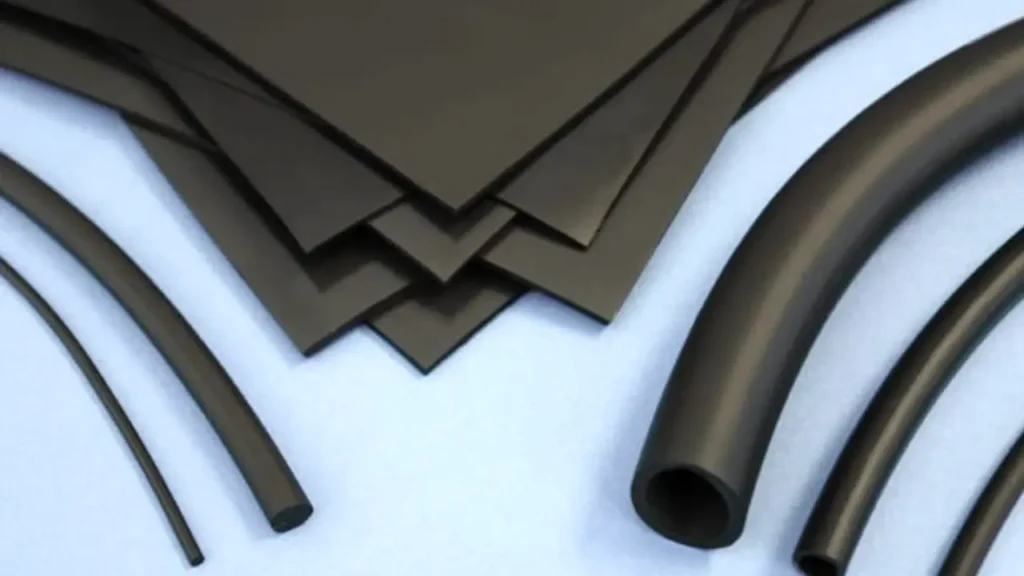

FKM, an acronym for Fluoroelastomer (Fluorine Kautschuk Material in German), is a family of high-performance synthetic rubbers renowned for their exceptional resistance to heat, chemicals, and oils.

Developed to meet demanding industrial needs, FKM materials are characterized by strong carbon-fluorine bonds, which provide their remarkable chemical inertness and thermal stability. This makes FKM an ideal choice for critical applications in various industries, including automotive, aerospace, oil and gas, and chemical processing, where traditional elastomers would degrade rapidly due to exposure to aggressive fluids, high temperatures, or harsh environments.

FKM Hydraulic Hose Benefits

FKM (fluoroelastomer) hydraulic hoses offer a range of superior benefits that make them ideal for the most demanding applications where standard rubber hoses would fail. Their unique chemical structure, characterized by strong carbon-fluorine bonds, provides exceptional performance in harsh environments. This makes FKM hoses a cost-effective solution in the long run, despite a higher initial investment, due to reduced downtime and replacement costs.

Key benefits of FKM hydraulic hoses include:

- Outstanding Chemical Resistance: FKM hoses are highly resistant to a vast array of aggressive chemicals, including various fuels (like diesel and biodiesel), oils, lubricants, solvents, acids, and bases. This prevents degradation, swelling, and cracking, ensuring the integrity of the hydraulic system.

- High-Temperature Performance: FKM can withstand extreme temperatures, typically operating continuously up to 200°C (392°F) and even higher for intermittent periods. This is crucial for hydraulic systems that generate significant heat or operate in hot environments.

- Low Permeation: FKM exhibits very low permeability to gases and liquids, which minimizes fluid loss, reduces emissions, and maintains system pressure more effectively. This is particularly important for volatile fluids or when maintaining a vacuum.

- Excellent Weather and Ozone Resistance: FKM hoses are highly resistant to degradation from UV radiation, ozone, and general weathering, making them suitable for outdoor applications and extending their service life significantly compared to other elastomers.

- Low Compression Set: FKM retains its elastic properties even after prolonged compression at high temperatures, ensuring a reliable and long-lasting seal within fittings and connections, preventing leaks in pressurized systems.

What is Viton?

Viton, in a general sense, refers to a type of fluoroelastomer (FKM), which is a high-performance synthetic rubber. While “Viton” is actually a registered trademark of The Chemours Company, it has become a widely recognized, almost generic, term for these specialized fluorocarbon rubbers due to its historical prevalence and significant market presence.

These materials are characterized by their exceptional resistance to high temperatures, aggressive chemicals, fuels, oils, and ozone, making them ideal for sealing and fluid transfer applications in demanding environments where other elastomers would quickly degrade.

Different “types” of Viton (like A, B, and F) vary in their specific chemical compositions and fluorine content, offering tailored resistance to a broader range of aggressive media, including various types of fuels and solvents.

Viton Hydraulic Hose Benefits

Viton, as a high-performance fluoroelastomer, offers significant benefits when used in hydraulic hoses, particularly in demanding and critical applications where conventional rubber materials would fail. Its unique chemical structure provides an unparalleled combination of properties that enhance hose longevity and system reliability.

Here are some key benefits of Viton hydraulic hoses:

- Exceptional Chemical Resistance: Viton exhibits superior resistance to a vast array of aggressive hydraulic fluids, including petroleum-based oils, synthetic hydraulic fluids, and even fire-resistant types. This prevents degradation, swelling, and softening of the hose material.

- High-Temperature Performance: Viton hoses maintain their mechanical properties and integrity over a wide temperature range, typically from approximately -20°C to 200°C (or even higher for short intermittent periods). This makes them ideal for systems operating in high heat environments.

- Low Permeability: Viton has extremely low permeability to gases and fluids, which minimizes fluid loss, reduces the risk of environmental contamination, and maintains system pressure more effectively.

- Excellent Weathering and Ozone Resistance: Hoses made with Viton are highly resistant to degradation from atmospheric oxidation, ozone, UV radiation, and general weathering, making them suitable for both indoor and outdoor hydraulic applications.

- Durability and Long Service Life: The robust nature of Viton results in hydraulic hoses with extended lifespans, reducing the frequency of replacements and associated maintenance costs and downtime.

FKM vs Viton

When choosing between FKM and Viton for your hydraulic hoses, understanding their core characteristics is essential. While often used interchangeably, subtle differences can impact performance, especially under specific operational demands.

Chemical Resistance

FKM materials generally offer broad chemical resistance to a wide range of aggressive fluids, including many acids, bases, and solvents. This makes them highly versatile for hydraulic systems exposed to various chemical environments. Their fluorine content contributes significantly to their inertness, preventing degradation from reactive substances that would typically destroy other elastomers.

Viton, being a brand of FKM, shares this excellent chemical resistance. However, different grades of Viton are specifically formulated to enhance resistance to particular chemical families. For instance, certain Viton grades excel against highly oxygenated fuels or specific industrial solvents, making them precisely tailored for niche, aggressive hydraulic fluid applications.

Temperature Range

FKM elastomers are known for their ability to withstand high temperatures, typically performing well in continuous service temperatures ranging from -20°C to 200°C (or even higher intermittently). This thermal stability is crucial for hydraulic systems that generate significant heat during operation, preventing material softening, embrittlement, or degradation.

Viton compounds also exhibit impressive high-temperature resistance, aligning with the general FKM capabilities. Some specialized Viton grades can push the upper temperature limits even further, offering enhanced performance in extreme thermal conditions. Conversely, certain Viton formulations are designed to improve low-temperature flexibility, a common challenge for many fluoroelastomers.

Compression Set Resistance

Compression set resistance refers to an elastomer’s ability to return to its original thickness after prolonged compression at a given temperature. FKM materials generally demonstrate excellent compression set resistance, meaning they maintain their sealing force over time. This property is vital for maintaining leak-free hydraulic connections and seals, especially in dynamic or frequently cycled systems.

Viton, as a premium FKM, often exhibits superior compression set resistance compared to generic FKM grades. This enhanced characteristic contributes directly to longer seal life and reduced maintenance in high-pressure or high-temperature hydraulic applications where maintaining a consistent seal is paramount.

Permeation Resistance

Permeation resistance is the ability of a material to prevent gases or liquids from passing through its matrix. FKM elastomers, due to their dense molecular structure and high fluorine content, generally offer very low permeability. This is a critical advantage in hydraulic systems handling volatile fluids or gases, as it minimizes fluid loss, prevents environmental contamination, and helps maintain system pressure.

Viton compounds are also celebrated for their excellent permeation resistance. Certain Viton grades are specifically engineered for ultra-low permeation, making them the preferred choice for highly sensitive applications or those involving expensive and hazardous hydraulic fluids where even minimal leakage is unacceptable.

Cost

The cost of FKM materials can vary significantly depending on the specific grade, fluorine content, and specialized additives. While generally more expensive than common elastomers like NBR or EPDM, FKM’s superior performance often justifies the higher initial investment through extended service life and reduced maintenance in demanding hydraulic applications.

Viton, being a branded, high-performance FKM, often comes at a premium price point compared to generic FKM materials. This higher cost reflects the extensive research, consistent quality, and specialized formulations that Chemours invests in its Viton products. However, for applications where failure is not an option and long-term reliability is paramount, the incremental cost of Viton is frequently outweighed by its performance benefits.

Here are some differences between FKM rubber and Viton as follows:

| Feature | FKM (General) | Viton (Chemours Brand of FKM) |

| Chemical Resistance | Excellent; broad resistance to fuels, oils, many chemicals | Excellent; specific grades for enhanced resistance to diverse aggressive chemicals |

| Temperature Range | High; typically -20°C to 200°C | High; comparable to FKM, some grades with improved low-temp or higher max temp |

| Compression Set Resist. | Excellent | Often superior due to specialized formulations |

| Permeation Resistance | Very Low | Excellent; some grades engineered for ultra-low permeation |

| Cost | High (compared to common rubbers) | Higher (premium brand, specialized grades) |

Considerations to Choose FKM and Viton Hydraulic Hoses

When selecting between FKM and Viton for your hydraulic hoses, several critical considerations should guide your decision to ensure optimal performance, longevity, and cost-effectiveness.

While Viton is a specific brand of FKM, the broader category of FKM encompasses various grades with differing properties. Understanding your specific application’s demands is paramount.

Here are key factors to consider:

Fluid Compatibility:

- Specific Fluid Chemistry: Beyond just “hydraulic fluid,” identify the exact chemical composition, including any additives, detergents, or biodiesel blends (e.g., B20, B100). Some FKM grades or specific Viton types are better suited for certain chemical aggressive media.

- Concentration: The concentration of aggressive chemicals can influence the material’s degradation rate.

Temperature Extremes:

- Operating Temperature Range: Determine both the continuous operating temperature and any intermittent peak temperatures the hose will experience. While both offer high heat resistance, some FKM or Viton grades provide better low-temperature flexibility or higher maximum service temperatures.

- Thermal Cycling: Frequent and rapid temperature changes can stress materials, so consider how often the system will cycle through hot and cold phases.

Pressure Requirements:

- System Pressure: Ensure the hose assembly’s pressure rating (working pressure and burst pressure) meets or exceeds your hydraulic system’s maximum operating and surge pressures. While FKM/Viton refers to the elastomer, the hose construction (reinforcement layers) dictates the pressure rating.

- Pressure Spikes: Account for any sudden pressure increases that might occur in the system.

Environmental Factors:

- External Exposure: Consider exposure to UV light, ozone, abrasion, and other environmental elements. While FKM/Viton generally excels here, specific formulations can offer enhanced resistance to particular external aggressors.

- Regulatory Compliance: Check if the application requires adherence to specific industry regulations or certifications (e.g., for food contact, medical, or specific industrial standards).

Cost vs. Performance:

- Life Cycle Cost: While Viton (branded FKM) might have a higher initial cost than generic FKM or other elastomers, its extended service life and reduced maintenance needs in critical applications often lead to a lower total cost of ownership.

- Risk of Failure: Assess the potential consequences of hose failure (downtime, environmental damage, safety hazards). For high-risk applications, investing in premium materials like Viton is often justified.

By carefully evaluating these considerations, you can make an informed decision, selecting the FKM or Viton hydraulic hose that provides the optimal balance of performance, durability, and cost-effectiveness for your specific application.

Conclusion

Ultimately, both FKM and Viton offer exceptional performance for hydraulic hoses in challenging environments. Your choice hinges on the specific chemical exposure, temperature extremes, and pressure demands of your application. Always verify the exact compound’s specifications for optimal compatibility.

While “Viton” is a widely recognized brand of FKM, understanding the nuances of different FKM grades is crucial. Investing in the right fluorocarbon elastomer ensures superior longevity, prevents costly failures, and maintains the integrity of your hydraulic systems.

For reliable, high-performance FKM hydraulic hoses at wholesale prices, consider trusted manufacturers.