Hydraulic hose markers are vital for identifying and tracking hydraulic lines in complex systems. They provide crucial information like pressure ratings, fluid types, and installation dates, ensuring safe and efficient maintenance. These markers minimize downtime by simplifying troubleshooting and preventing costly errors.

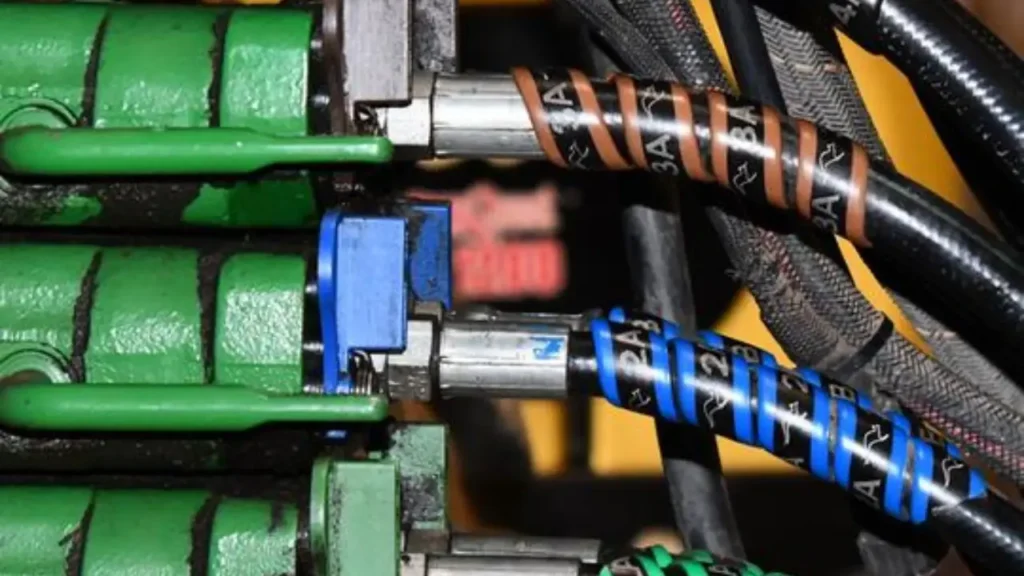

Essentially, these markers are durable labels or tags applied to hydraulic hoses. They use color-coding, text, or barcodes to convey essential data, enabling quick visual identification. This system streamlines operations, especially in industries like construction and manufacturing, where hydraulic systems are prevalent.

What Are Hydraulic Hose Markers

Hydraulic hose markers are essential tools designed to provide clear identification and organization for hydraulic hoses.

These hydraulic hose markers serve a crucial role in various industries, particularly those involving heavy machinery and complex hydraulic systems. They are more than just simple tags; they are a system for improving safety and efficiency.

What Are Hydraulic Hose Markers Used for

Hydraulic hose markers serve several critical purposes, primarily centered around safety, maintenance, and efficiency within hydraulic systems. Here are some hydraulic hose marker uses:

Identification:

They allow for quick and accurate identification of individual hoses, which is essential in complex hydraulic systems. This helps prevent mix-ups during maintenance or repairs.

Markers can convey important information such as hose type, size, pressure ratings, fluid compatibility, and installation dates.

Safety:

Clear marking reduces the risk of incorrect hose connections, which can lead to equipment malfunctions, leaks, and potentially dangerous accidents.

Providing clear information about pressure ratings and fluid types helps ensure that hoses are used within their safe operating limits.

Maintenance:

Hose markers facilitate efficient maintenance and inspections by providing easy access to crucial information.

They help track hose lifecycles, enabling timely replacements and preventing unexpected failures.

They can aid in trouble shooting.

Compliance:

In many industries, clear hose labeling is required to comply with safety regulations and standards.

Proper labeling helps ensure that hydraulic systems are operated in accordance with industry best practices.

Efficiency:

By streamlining identification and maintenance processes, hose markers contribute to reduced downtime and increased productivity.

In essence, hydraulic hose markers are a fundamental component of safe and efficient hydraulic system management.

Hydraulic Hose Color Markers

Hydraulic hose color markers are a valuable tool for visual identification within hydraulic systems, adding an extra layer of clarity and safety. These markers utilize color-coding to quickly distinguish between different hoses, simplifying complex systems and reducing the potential for errors.

Here’s how color markers contribute to effective hydraulic system management:

Rapid Visual Identification:

- Color-coding allows operators and maintenance personnel to instantly recognize specific hoses, even in cluttered or dimly lit environments.

- This speeds up maintenance procedures, troubleshooting, and hose connection processes.

Enhanced Safety:

- Color markers can indicate critical information, such as pressure ratings, fluid types, or specific functions. This helps prevent accidental misconnections or the use of incorrect hoses, which could lead to equipment damage or safety hazards.

- This is especially important when many hydraulic lines are located in close proximity.

Organization and Standardization:

- Implementing a consistent color-coding system across a facility or fleet of equipment promotes organization and standardization.

- This simplifies training, reduces confusion, and ensures that everyone follows the same identification protocols.

In practice, these color markers come in many forms, from wrap around tags, to painted on markers. The important factor is that a company or work site has a consistent standard for the color coding that they use.

Hydraulic Hose Color Marker Chart

Note: This is a sample chart and may not be universally applicable. Color coding systems can vary depending on industry standards, company practices, and specific system requirements.

| Color | Possible Meaning |

| Red | High-pressure lines, Fire-resistant fluids |

| Blue | Low-pressure lines, Return lines |

| Yellow | Hydraulic oil, General purpose |

| Green | Lubrication lines, Coolant lines |

| Black | Exhaust lines, Grounding |

| White | Air lines, Instrument lines |

| Orange | Warning/Caution |

| Purple | Special fluids (e.g., synthetic oils) |

Important Considerations:

- Consistency: The most crucial aspect is to maintain consistency within a specific system or facility.

- Clarity: Choose colors that are easily distinguishable from each other and the surrounding environment.

- Safety: Avoid using colors that could be confused with safety signals (e.g., red for fire extinguishers).

- Documentation: Always document the chosen color coding system for future reference.

Example:

- If red is designated for high-pressure lines, all high-pressure lines within the system should be consistently marked with red.

Disclaimer: This information is for general guidance only. Consult relevant industry standards and safety regulations for specific requirements.

I recommend consulting with industry experts or referring to specific standards (such as those from ISO or relevant industry associations) for the most accurate and up-to-date color coding guidelines.

This information should not be considered professional advice. Always consult with qualified professionals for guidance on specific applications.

How to Use Hydraulic Hose Markers

Effectively using hydraulic hose markers is crucial for safety and efficiency. This guide outlines a step-by-step process, starting with thorough planning and system assessment. Proper marker application ensures clear identification, reduces errors, and simplifies maintenance.

Step 1: Planning and System Assessment

Before applying any markers, it’s crucial to understand your hydraulic system thoroughly. This involves reviewing system diagrams, identifying hose functions, and determining the necessary information to include on the markers. A well-planned marking system will save time and prevent future confusion.

Consider factors like hose pressure ratings, fluid types, installation dates, and specific circuit functions. Developing a clear and consistent labeling scheme is essential for maintaining a safe and efficient hydraulic system. Document your chosen system to ensure everyone involved understands and can implement the marking procedures.

Step 2: Selecting the Appropriate Markers

Choose markers that are compatible with the environment and the hoses themselves. Consider factors like material durability, resistance to chemicals and UV exposure, and the ease of application. Options include wrap-around tags, adhesive labels, color-coded sleeves, and engraved metal tags.

Ensure the chosen markers provide sufficient space for the required information and are easily visible. The markers should also be securely attached to the hoses to prevent them from becoming loose or damaged over time. Select markers that will not degrade the hydraulic hose material.

Step 3: Preparing the Hose Surface

Clean the hose surface thoroughly before applying any markers. Remove any dirt, grease, or debris that could interfere with adhesion or visibility. Use a suitable cleaning agent that won’t damage the hose material.

If using adhesive labels, ensure the hose surface is completely dry. For wrap-around tags or sleeves, check that the hose diameter is compatible with the marker size. Proper surface preparation is essential for ensuring the markers remain securely attached and legible over time.

Step 4: Applying the Markers

Apply the markers according to the manufacturer‘s instructions. Ensure they are securely fastened and positioned for optimal visibility. For adhesive labels, press firmly to ensure proper adhesion. For wrap-around tags, tighten securely without damaging the hose.

Double-check that the information on the markers is accurate and legible. Maintain consistency in marker placement and orientation across all hoses in the system. Document the placement and meaning of the markers.

Step 5: Verification and Documentation

After applying the markers, verify that all information is correct and legible. Inspect the markers for secure attachment and proper positioning. Document the marking system, including the meaning of each marker and its location.

Create a record of the marking system, including photographs or diagrams if necessary. This documentation will serve as a valuable reference for maintenance personnel and operators, ensuring consistency and accuracy in future work. Perform periodic inspections to ensure markers remain in good condition.

Conclusion

Hydraulic hose markers are vital for safety and maintenance, providing clear identification and preventing costly errors. They streamline inspections and replacements, ensuring systems operate efficiently. Understanding their function and application is crucial for anyone working with hydraulic systems.

Properly marked hoses enhance workplace safety and reduce downtime. Implementing a consistent marking system allows for quick identification of pressure ratings, fluid types, and installation dates, minimizing risks associated with incorrect hose usage.

Invest in reliable hydraulic hose markers to optimize your operations. For high-quality hydraulic hoses and personalized quotes, contact Gushan Rubber today.