Hydraulic hose reinforcement is crucial for ensuring its strength, durability, and ability to withstand the pressures encountered in various applications.

This blog post will explore the three primary types of hose reinforcement: braided, spiral, and helical. We’ll delve into their unique characteristics, advantages, and ideal applications, helping you understand how these reinforcements contribute to the overall performance and reliability of hydraulic hoses.

What is Hydraulic Hose Reinforcement

Hydraulic hose reinforcement is the structural element within the hose that gives it the strength and durability to withstand the pressures and stresses encountered in hydraulic systems. It essentially provides the backbone of the hose, enabling it to safely and effectively transmit hydraulic fluid under pressure.

Reinforcement typically consists of multiple layers of materials, such as steel wire or synthetic fibers, embedded within the hose’s structure. These layers work together to:

- Withstand Internal Pressure: The primary function of reinforcement is to counteract the internal pressure exerted by the hydraulic fluid flowing through the hose.

- Maintain Hose Shape: Reinforcement helps maintain the hose’s shape and prevents it from collapsing or expanding excessively under pressure.

- Resist External Forces: Reinforcement protects the hose from external forces such as abrasion, kinking, and crushing, which can occur during installation, operation, and handling.

- Enhance Flexibility: While providing strength, the reinforcement must also allow for a degree of flexibility to enable the hose to be routed through tight spaces and accommodate movement within the hydraulic system.

The type and number of reinforcement layers vary depending on the specific hose design and the intended application. Common types of reinforcement include braided, spiral, and helical configurations, each offering unique characteristics in terms of strength, flexibility, and pressure resistance.

Types of Hydraulic Hose Reinforcement

Hydraulic hose reinforcement is the critical structural element within a hose that provides the strength and durability necessary to withstand the pressures and stresses encountered in hydraulic systems. It’s essentially the “backbone” of the hose, ensuring safe and reliable fluid transmission.

Here’s a deeper look at the common types of reinforcement:

1. Braided Reinforcement

Construction: This method involves weaving strands of material, typically steel wire or synthetic fibers, into a braided pattern around the inner tube of the hose.

Advantages:

- Offers excellent flexibility and bend radius, allowing the hose to be easily routed through tight spaces.

- Provides good resistance to internal pressure and external forces like abrasion and kinking.

Types:

- Single Braid: One layer of braided wire provides good flexibility and is suitable for medium-pressure applications.

- Double Braid: Two layers of braided wire offer significantly increased strength and pressure resistance, ideal for high-pressure applications.

2. Spiral Reinforcement

Construction: Involves a single layer of steel wire wound spirally around the inner tube.

Advantages:

- Provides excellent resistance to internal pressure and external forces.

- Offers a good balance of strength and flexibility.

Limitations:

May have slightly less flexibility compared to braided hoses.

3. Helical Reinforcement

Construction: Similar to spiral reinforcement but with a slightly different wire winding pattern.

Advantages:

- Offers high strength and pressure resistance.

- Can provide good flexibility depending on the specific helical pattern.

Applications:

Often used in high-pressure applications where strength and durability are paramount.

Comparison of Hydraulic Hose Reinforcement Types

| Reinforcement Type | Characteristics | Advantages | Limitations |

|---|---|---|---|

| Braided (Single) | Single layer of braided wire | Good flexibility, cost-effective | Lower pressure rating |

| Braided (Double) | Two layers of braided wire | High strength, good flexibility | May be slightly more expensive |

| Spiral | Single layer of spirally wound wire | Excellent pressure resistance, good balance of strength and flexibility | May have slightly less flexibility than braided |

| Helical | Similar to spiral, with a different wire winding pattern | High strength, good pressure resistance | Flexibility can vary depending on the helical pattern |

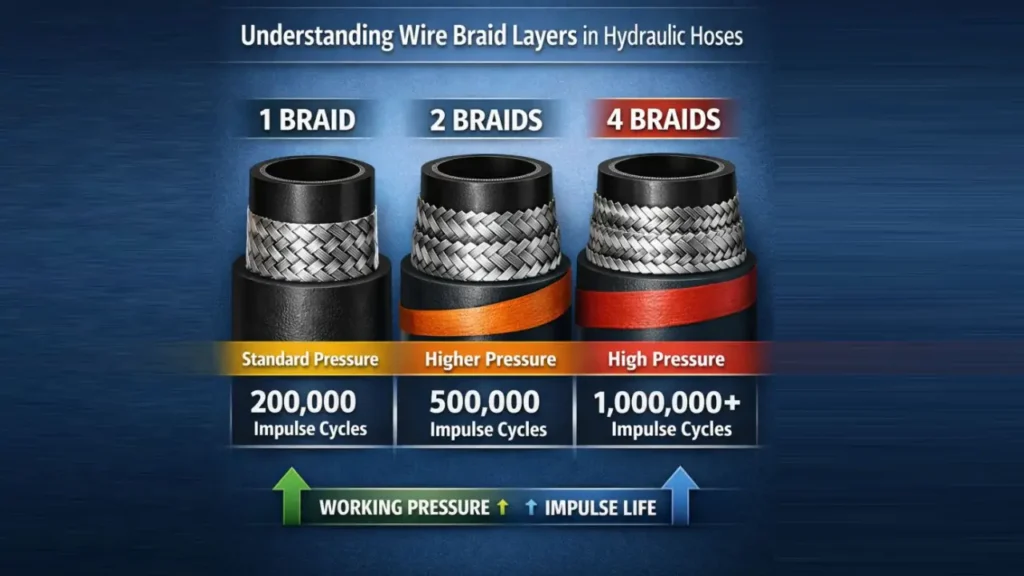

Wire Braided Layers in Hydraulic Hoses

Wire braided layers play a key role in determining a hydraulic hose’s pressure capacity, flexibility, and service life. By increasing the number of wire braids, manufacturers enhance strength and impulse resistance while maintaining controlled flexibility. Understanding how different braid layers perform helps users select hoses that match operating pressure, safety requirements, and long-term reliability needs.

- 1 Wire Braid (Single Braid Hose) – A single wire braid hydraulic hose is designed for standard-pressure applications where flexibility and easy routing matter most, offering moderate working pressure capability and lower impulse life, commonly used in light-duty machinery, compact hydraulic systems, and industrial equipment with stable operating conditions.

- 2 Wire Braids (Double Braid Hose) – Two wire braids increase reinforcement strength and impulse resistance while maintaining reasonable flexibility, making these hoses suitable for higher-pressure systems, construction equipment, agricultural machinery, and mobile hydraulics that experience pressure spikes, vibration, and longer daily operating cycles.

- 4 Wire Braids (High-Pressure Hose) – Four wire braids deliver maximum pressure capacity and outstanding impulse life, allowing hoses to perform reliably under extreme pressure loads, harsh environments, and continuous shock conditions common in mining, heavy construction, oil and gas, and severe industrial applications.

4 Wire Spiral Hydraulic Hose vs 6 Wire

Spiral hydraulic hoses are designed for high-pressure and high-impulse applications, offering superior strength and durability compared to braided hoses. The key to their strength lies in the multiple layers of high-tensile steel wire wound in a continuous spiral pattern around the inner tube.

Here are the primary types of spiral hydraulic hoses, focusing on their wire reinforcement:

4-Wire Spiral Hydraulic Hose (e.g., SAE 100R12, some 100R13):

- Construction: These hoses feature four layers of spiraled high-tensile steel wire reinforcement. The wires are typically wound in alternating directions to maximize strength and resist expansion under pressure.

- Pressure Rating: They are designed for high-pressure hydraulic systems, generally suitable for constant working pressures up to 420 bar (around 6,100 psi) or even higher depending on the specific standard (like SAE 100R12).

- Applications: Widely used in heavy-duty mobile equipment, construction machinery, mining, and industrial hydraulic systems where high pressure and impulse resistance are critical. They offer a good balance of strength and flexibility for their pressure rating.

- Common Standard: Often meet or exceed SAE 100R12 and, for some sizes, the lower end of SAE 100R13 specifications.

6-Wire Spiral Hydraulic Hose (e.g., SAE 100R13, 100R15):

- Construction: These hoses are reinforced with six layers of spiraled high-tensile steel wire. This increased number of reinforcement layers provides even greater burst strength and fatigue resistance.

- Pressure Rating: Capable of handling extremely high constant working pressures, typically 350 bar (5,075 psi) for all diameters in SAE 100R13, and even up to 420 bar (6,000 psi) for SAE 100R15.

- Applications: Essential for ultra-high-pressure hydraulic systems found in very heavy machinery, oil and gas exploration, large construction equipment, and other demanding applications where maximum power transmission and safety are paramount.

- Common Standard: Primarily found in SAE 100R13 (especially for larger diameters) and SAE 100R15, which are among the highest pressure rated hydraulic hoses.

General Characteristics of Spiral Hydraulic Hoses:

- High Pressure and Impulse Resistance: The spiraled wire construction provides superior resistance to pressure spikes and continuous high-pressure cycles compared to braided hoses.

- Durability: Their robust construction makes them highly resistant to abrasion, kinks, and external damage, contributing to a longer service life.

- Reduced Flexibility (Compared to Braided): Due to the dense wire reinforcement, spiral hoses are generally stiffer and have a larger bend radius than braided hoses, though advancements are improving flexibility.

- Fluid Compatibility: Typically feature an inner tube made of synthetic rubber resistant to a wide range of hydraulic fluids, including petroleum-based, water-glycol, and some synthetic oils.

- Temperature Range: Designed to operate effectively across a broad temperature range, usually from -40°C to +121°C.

When selecting between 4-wire and 6-wire spiral hoses, the primary considerations are the required operating pressure, the severity of impulse cycles, and the hose diameter. Larger diameter hoses requiring extremely high pressure often necessitate a 6-wire construction to maintain their pressure rating.

Hydraulic Hose Spiral vs Braided

When choosing between spiral and braided hydraulic hoses, consider the specific demands of your application. The key differences revolve around their construction, flexibility, and pressure handling capabilities.

- These hydraulic hoses use a crisscross, braided pattern of steel wire for reinforcement.

- They offer excellent flexibility, making them ideal for applications with tight bends or frequent movement.

- Typically used for low to medium-high pressure applications.

- These hydraulic hoses feature multiple layers of high-tensile steel wire wound in a spiral pattern.

- They are designed for very high-pressure and high-impulse applications.

- While robust, they are less flexible than braided hoses.

Here is the chart about the differences between spiral hydraulic hoses and braided:

| Characteristic | Spiral Hydraulic Hose | Braided Hydraulic Hose |

| Construction | Multiple layers of steel wire wound in a spiral pattern | Steel wire woven in a crisscross, braided pattern |

| Flexibility | Less flexible, larger bend radius | Highly flexible, smaller bend radius |

| Pressure Handling | Designed for very high pressure and high-impulse applications | Suitable for low to medium-high pressure applications |

| Applications | Heavy machinery (excavators, mining equipment), high-pressure systems | Hydraulic lifts, engine systems, applications requiring flexibility |

Why Hydraulic Hose Reinforcement Is Important

Hydraulic hose reinforcement is absolutely critical for several reasons:

Withstands Internal Pressure: The primary function of reinforcement is to counteract the immense pressure exerted by the hydraulic fluid flowing within the hose. Without adequate reinforcement, the hose could burst or rupture, leading to catastrophic failures, fluid leaks, and potential injuries.

Maintains Structural Integrity: Reinforcement provides the strength to maintain the hose’s shape and prevent it from collapsing or expanding excessively under pressure. This ensures consistent fluid flow and prevents the hose from deforming or damaging during operation.

Resists External Forces: Reinforcement protects the hose from various external forces it may encounter, such as:

- Abrasion: Protects the hose from wear and tear caused by rubbing against other surfaces.

- Kinking: Prevents the hose from bending excessively, which can restrict fluid flow and weaken the hose structure.

- Crushing: Protects the hose from being crushed by external forces, such as heavy equipment or machinery.

Ensures System Safety: By providing the necessary strength and durability, reinforcement significantly enhances the safety of the entire hydraulic system. It helps prevent leaks, which can lead to fluid loss, contamination, and potential fire hazards.

In essence, hydraulic hose reinforcement is the backbone of the hose, ensuring its ability to withstand the demands of the application and operate safely and reliably within the hydraulic system.

How to Choose the Right Hydraulic Hose Reinforcement

Selecting the appropriate reinforcement for your hydraulic hose is crucial for optimal performance, safety, and longevity. Here are key factors to consider:

1. Operating Pressure:

High-Pressure Applications:

- Require strong reinforcement, such as double-wire braid or spiral wire, to withstand the high internal pressures.

- These reinforcement types provide excellent resistance to burst and maintain hose integrity under demanding conditions.

Medium-Pressure Applications:

- Single-wire braid reinforcement is typically sufficient for medium-pressure applications.

- This offers a good balance of strength and flexibility.

2. Flexibility Requirements:

Applications requiring high flexibility:

- Single-wire braid reinforcement generally offers greater flexibility, allowing for easier routing and installation in tight spaces.

Applications with limited flexibility:

Spiral or helical reinforcement, while providing high strength, may have slightly less flexibility.

3. Environmental Factors:

Abrasion Resistance: If the hose is exposed to abrasive surfaces, consider reinforcement options that offer superior abrasion resistance, such as double-wire braid or specialized covers.

Temperature Extremes:

- Extreme temperatures can affect hose performance.

- Select reinforcement materials that can withstand the expected temperature range without compromising strength or flexibility.

Chemical Exposure:

If the hose will be exposed to chemicals, choose reinforcement materials that are resistant to corrosion and chemical degradation.

4. Application Specifics:

Heavy-Duty Applications:

Consider double-wire braid or spiral reinforcement for applications involving heavy machinery, construction equipment, and other demanding environments.

General Industrial Use:

Single-wire braid reinforcement may be sufficient for many general industrial applications.

By carefully considering these factors, you can select the hydraulic hose with the optimal reinforcement for your specific needs, ensuring safe, reliable, and efficient operation of your hydraulic system.

Reinforced Hydraulic Hoses

Hydraulic hoses are essential components in various industries, transmitting hydraulic fluid under pressure to power machinery. To withstand these demanding conditions, they require robust reinforcement. Steel-reinforced hydraulic hoses are a common choice due to their exceptional strength and durability.

Steel Wire Reinforced Hydraulic Hose

This type of hose utilizes one or more layers of braided steel wire within the hose structure. The steel wire provides significant strength, enabling the hose to handle high pressures and resist internal pressure surges. Steel wire reinforcement also enhances the hose’s resistance to abrasion, kinking, and external damage.

Textile Reinforced Hydraulic Hose

Textile-reinforced hydraulic hoses use woven fabrics, such as polyester or nylon, for reinforcement. While not as strong as steel, textile reinforcement offers good flexibility and resistance to abrasion. These hoses are often preferred in applications where flexibility is paramount and where the pressure demands are moderate.

Both steel wire and textile-reinforced hydraulic hoses have their own advantages and are suitable for different applications based on the specific requirements of pressure, flexibility, and working environment.

Conclusion

The choice of reinforcement for your hydraulic hose significantly impacts its performance, durability, and suitability for specific applications. Braided hoses, whether single-wire or double-wire, offer excellent flexibility and resistance to bending.

Spiral hoses are highly strong and well-suited for high-pressure applications. Helical hoses offer a unique combination of flexibility and strength, making them suitable for a wide range of applications.

By carefully considering the operating pressures, temperatures, and other factors specific to your application, you can select the appropriate hose reinforcement to ensure optimal performance, reliability, and safety within your hydraulic system.

Ready to upgrade your hydraulic system with high-quality reinforced hoses?

Contact us today for a bulk order quote and experience the difference.