Hydraulic hoses are essential components in numerous industrial and mechanical systems, from construction equipment to manufacturing processes. These flexible tubes transmit high-pressure hydraulic fluid, powering various operations.

However, the effectiveness and safety of these systems heavily rely on the pressure rating of the hoses.

In this blog, we are diving into the details about hydraulic hose pressure rating.

What is Hydraulic Hose Pressure Rating

Hydraulic hose pressure rating is a critical factor to consider when selecting a hose for your specific application. It determines the maximum pressure a hydraulic hose can safely handle without failing.

There are two main types of pressure ratings:

- Working Pressure: This is the maximum pressure a hose can safely handle during normal operation.

- Burst Pressure: This is the maximum pressure a hose can withstand before rupturing.

Understanding these ratings is essential to ensure the safe and efficient operation of your hydraulic system.

Working Pressure vs Burst Pressure

When selecting a hydraulic hose, it’s crucial to understand the different pressure ratings associated with it. These ratings ensure safe and efficient operation of your hydraulic system.

Hydraulic Hose Working Pressure:

- This is the maximum pressure a hose can safely handle during normal operation.

- It’s the standard operating pressure for the hydraulic hose.

Working pressure refers to the maximum pressure a hydraulic hose is designed to handle during normal, continuous operation. It’s a critical specification that ensures the hose functions safely and reliably within a hydraulic system. Manufacturers determine working pressure through rigorous testing and adhere to industry standards, providing a safety margin to account for potential fluctuations and dynamic stresses within the system.

Selecting the correct working pressure for a hydraulic hose is paramount for preventing premature failure and ensuring system integrity. Operating a hose beyond its rated working pressure can lead to leaks, bursts, and catastrophic failures, posing significant safety risks and causing costly downtime.

Factors such as fluid temperature, flow rate, and the frequency of pressure surges all influence the actual stress experienced by the hose. Therefore, it’s essential to consider these variables when selecting a hose and to consult manufacturer specifications for accurate working pressure ratings.

Furthermore, hydraulic system designers and operators must implement proper maintenance practices to maintain the hose’s working pressure capacity. Regular inspections for signs of wear, damage, or degradation are crucial.

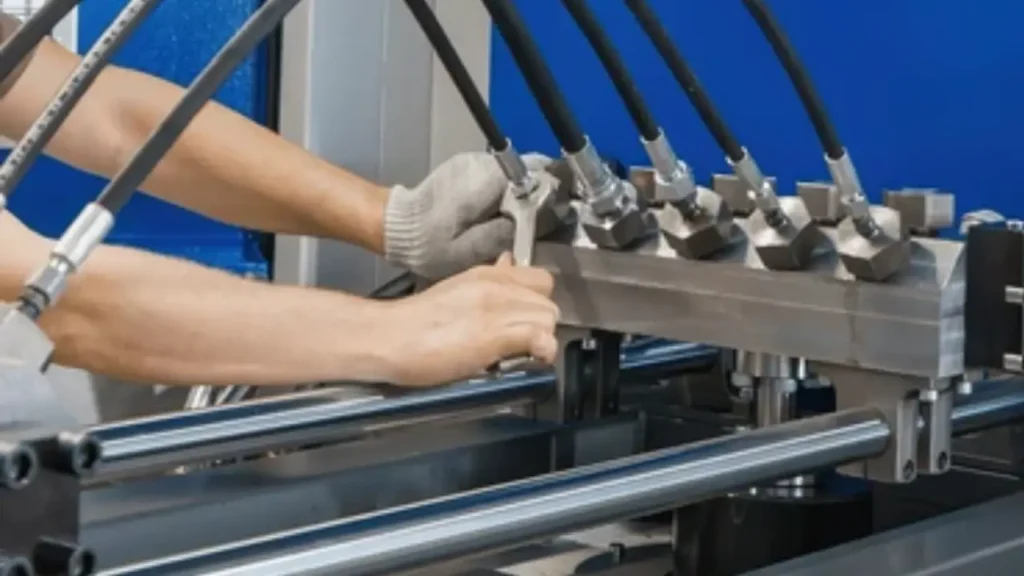

Replacing hydraulic hoses at recommended intervals or when damage is detected prevents unexpected failures. Proper installation, including correct fitting selection and torque, also ensures that the hose operates within its intended working pressure limits.

Hydraulic Hose Burst Pressure:

- This is the maximum pressure a hose can withstand before rupturing.

- Typically, burst pressure is 4 times the working pressure.

Burst pressure is the pressure at which a hydraulic hose is expected to rupture or fail catastrophically. It’s a critical safety parameter that indicates the hose’s ultimate strength and resistance to extreme pressure. Manufacturers determine burst pressure through destructive testing, subjecting hoses to increasing pressure until failure occurs. This data is used to establish safety factors and ensure that the working pressure remains well below the burst pressure.

The burst pressure is significantly higher than the working pressure, typically by a factor of four or more. This safety factor is designed to accommodate unexpected pressure spikes, surges, and other dynamic stresses that may exceed the normal operating conditions.

It also accounts for potential degradation of the hose over time due to factors such as aging, abrasion, and chemical exposure. Therefore, even if a hydraulic system experiences a temporary pressure surge, the hose should remain intact as long as the burst pressure is not reached.

It is important to understand that while burst pressure provides a safety margin, it should never be intentionally approached or exceeded during normal operation. Operating a hose near its burst pressure significantly increases the risk of failure and poses a severe safety hazard. The safety factor is a safety measure, not an operating range.

Regular maintenance, proper installation, and adherence to working pressure limits are essential for preventing catastrophic failures and ensuring the safe operation of hydraulic systems.

Hydraulic Hose Testing Pressure:

- This is the pressure used to test the hose’s integrity during manufacturing or before hydraulic hose installation.

- It’s usually 2 times the working pressure.

Why These Ratios Matter:

- Safety Factor: The higher burst pressure provides a safety margin, ensuring the hose can withstand unexpected pressure spikes or surges.

- Quality Assurance: Testing the hose at twice the working pressure verifies its strength and durability.

Hydraulic Hose Pressure Ratings

| Pressure Type | Description | Typical Ratio to Working Pressure |

|---|---|---|

| Working Pressure | Maximum safe operating pressure | 1x |

| Burst Pressure | Maximum pressure before rupture | 4x |

| Testing Pressure | Pressure used for quality assurance testing | 2x |

By understanding these pressure ratings and their relationships, you can select the appropriate hydraulic hose for your specific application, ensuring the safety and reliability of your hydraulic system.

How to Test Hydraulic Hose Pressure

Testing hydraulic hoses involves high pressures and can be dangerous. Always prioritize safety and consult with a qualified professional or follow specific manufacturer‘s guidelines.

Visual Inspection:

- Check for any visible damage, such as cuts, cracks, or excessive wear.

- Inspect the fittings for proper tightness and signs of leakage.

Hydraulic Hose Pressure Testing:

Prepare the Test Setup:

- Secure the hose to a testing bench or jig.

- Connect a high-pressure pump to one end of the hose.

- Attach a pressure gauge to the other end.

Gradually Increase Pressure:

- Slowly increase the pressure in the hose using the pump.

- Monitor the pressure gauge closely.

Observe for Failure:

- Watch for any signs of leakage, ballooning, or rupture.

- If the hose fails, note the pressure at which it failed.

Specific Testing Methods:

Burst Test:

- Increase the pressure until the hose ruptures.

- This test determines the maximum pressure the hose can withstand before failing.

Proof Test:

- Apply a pressure equal to or greater than the hose’s working pressure for a specified duration.

- This test verifies the hose’s ability to withstand its rated pressure without leaking or failing.

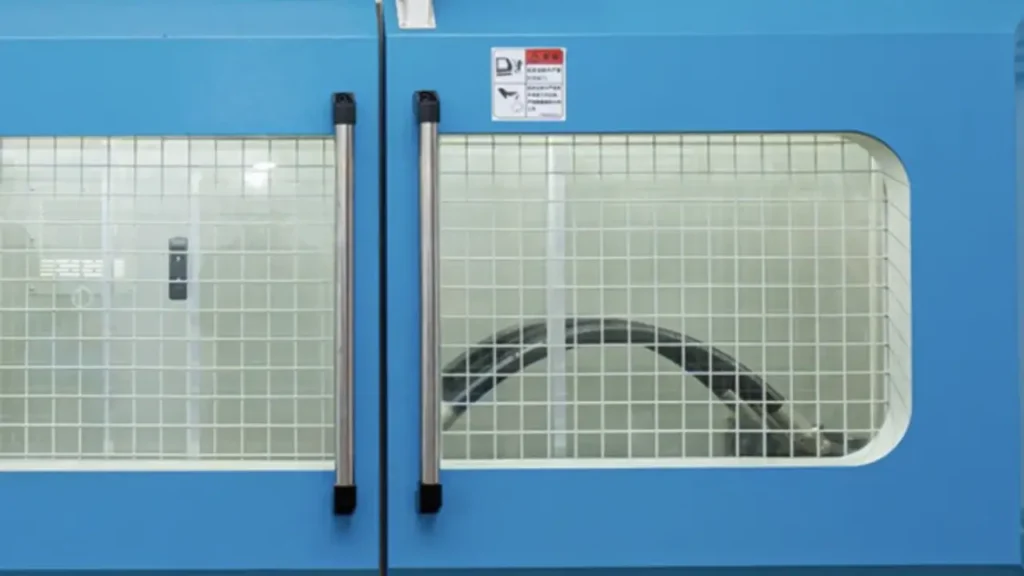

Impulse Test:

- Subject the hose to repeated cycles of high-pressure pulses.

- This test simulates real-world conditions and evaluates the hose’s resistance to fatigue.

Safety Precautions:

- Wear protective gear: Safety glasses, gloves, and protective clothing.

- Work in a controlled environment: Avoid testing in areas with potential hazards.

- Use proper equipment: Ensure the pump and pressure gauge are calibrated and in good working condition.

- Be aware of potential risks: High-pressure hydraulic systems can be dangerous.

It’s important to consult with a hydraulic hose specialist or a qualified testing facility for accurate and safe pressure testing. They have the necessary expertise and equipment to perform these tests according to industry standards.

Why Hydraulic Hose Pressure Matters

Hydraulic hose pressure matters for several reasons:

1. Safety:

- Preventing catastrophic failure: Operating a hydraulic hose beyond its pressure rating can lead to catastrophic failure, potentially causing injury to personnel, damage to equipment, and environmental hazards.

- Ensuring safe operation: Selecting a hose with an appropriate pressure rating ensures that the system operates within safe parameters, reducing the risk of accidents.

2. Efficiency:

- Optimal performance: A properly rated hose allows for efficient fluid flow and pressure transmission, maximizing the performance of hydraulic systems.

- Avoiding pressure drops: Undersized or incorrectly rated hoses can lead to pressure drops, reducing the system’s efficiency and power output.

3. Durability:

- Prolonged lifespan: Operating a hose within its pressure limits helps to extend its lifespan by minimizing stress and wear on the hose material.

- Preventing premature failure: Exceeding the pressure rating can cause premature failure, leading to increased maintenance costs and downtime.

4. Reliability:

- Consistent performance: Selecting a hose with a suitable pressure rating ensures consistent performance and reliability over time.

- Minimizing downtime: By preventing failures, properly rated hoses contribute to reduced downtime and increased productivity.

Hydraulic hose pressure matters because it directly impacts the safety, efficiency, durability, and reliability of hydraulic systems. By understanding and selecting the correct pressure rating, you can ensure the optimal performance and longevity of your equipment.

Factors Affecting Pressure Rating

Several factors can affect the pressure rating of a hydraulic hose:

Hose Construction:

- Materials: The type of materials used in the hose’s construction, including the inner tube, reinforcement layers, and outer cover, significantly impacts its pressure rating. Higher-strength materials can withstand higher pressures.

- Reinforcement Layers: The number and type of reinforcement layers, such as wire braids or textile fibers, influence the hose’s ability to resist internal pressure. More reinforcement layers generally result in higher pressure ratings.

- Wall Thickness: The thickness of the hose wall affects its strength and pressure capacity. Thicker walls can handle higher pressures.

Fluid Compatibility:

- Chemical Resistance: The compatibility of the hose materials with the hydraulic fluid is crucial. Some fluids can degrade hose materials over time, reducing their pressure-bearing capacity.

- Fluid Temperature: The operating temperature of the fluid can affect the hose’s pressure rating. Higher temperatures can reduce the strength of the hose material.

Operating Conditions:

- Temperature Range: The temperature range at which the hose operates can influence its pressure rating. Extreme temperatures, both high and low, can affect the hose’s material properties and reduce its pressure capacity.

- Pressure Pulses and Vibration: Exposure to pressure pulses and vibration can accelerate hose wear and fatigue, potentially reducing its pressure rating over time.

- Bending Radius: Excessively bending the hose can weaken its structure and reduce its pressure rating.

Additional Factors:

- Hose Diameter: Larger diameter hoses generally have higher pressure ratings due to their increased wall thickness and reinforcement.

- Hydraulic Hose Manufacturer’s Specifications: The manufacturer‘s specifications for a particular hose model should be strictly followed to ensure safe and reliable operation.

By carefully considering these factors and selecting a hose with a pressure rating that exceeds the maximum operating pressure of your hydraulic system, you can ensure the safety and efficiency of your equipment.

How to Select the Right Hydraulic Hose

Selecting the right hydraulic hose is crucial for the safe and efficient operation of your hydraulic system. Here are the key factors to consider when making your selection:

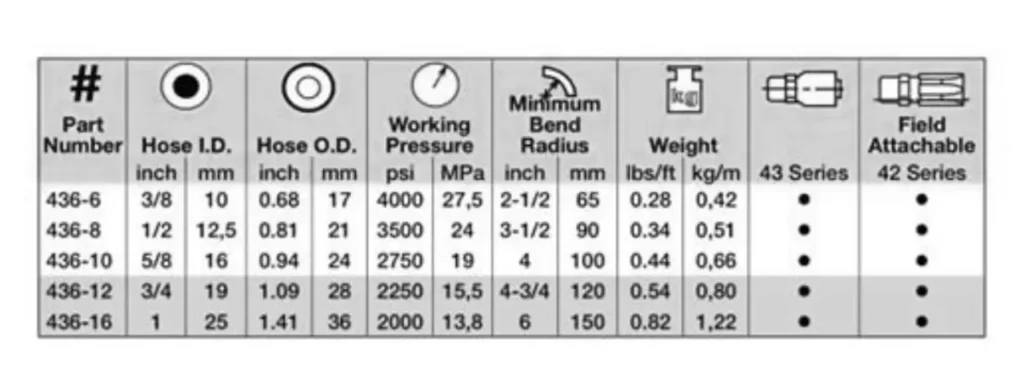

1. Pressure Rating:

- Working Pressure: Ensure the hose’s working pressure rating is equal to or greater than the maximum system operating pressure.

- Burst Pressure: This is the maximum pressure the hose can withstand before rupturing. It’s a safety factor, typically four times the working pressure.

2. Temperature Rating:

- Fluid Temperature: Consider the temperature of the hydraulic fluid. The hose must be compatible with both high and low temperatures.

- Ambient Temperature: The temperature of the environment where the hose will be used also affects its performance.

3. Fluid Compatibility:

- Chemical Resistance: The hose material must be compatible with the specific hydraulic fluid to prevent degradation and potential failure.

4. Hose Size:

- Inside Diameter (ID): The ID determines the flow rate of the fluid. Choose the appropriate ID based on your system’s flow requirements.

- Outside Diameter (OD): The OD influences the hose’s flexibility and durability.

5. Hose Construction:

- Reinforcement Layers: The number and type of reinforcement layers affect the hose’s pressure rating and flexibility.

- Cover Material: The cover material protects the hose from abrasion, weather, and other external factors.

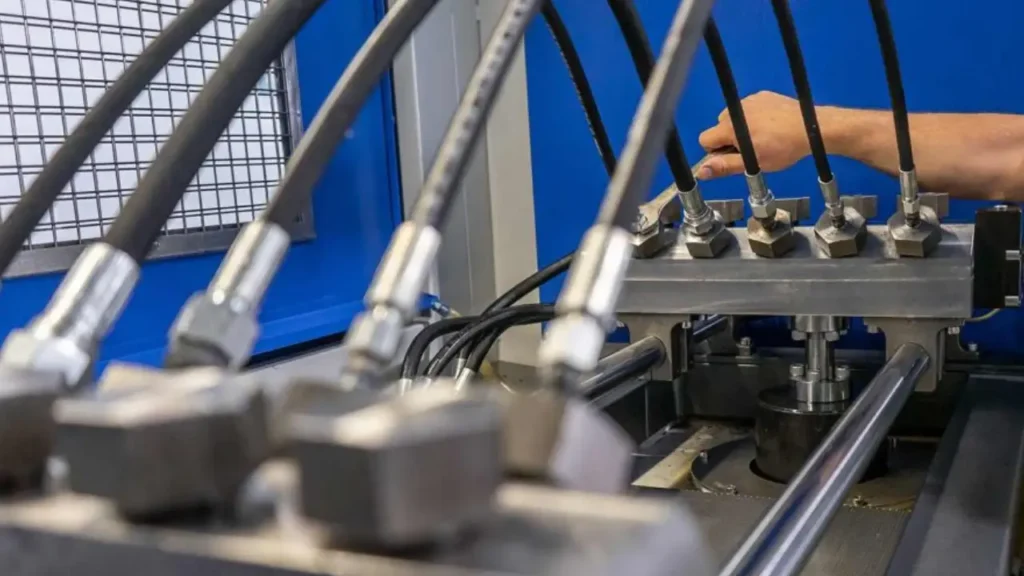

6. End Fittings:

- Compatibility: The fittings must be compatible with both the hose and the system components.

- Sealing: Ensure proper sealing to prevent leaks.

7. Application and Environment:

- Flexibility: Consider the degree of flexibility required for the application.

- Abrasion Resistance: If the hose will be exposed to abrasive environments, choose a hose with a durable cover.

- Weather Resistance: If the hose will be used outdoors, select a weather-resistant hose.

8. Manufacturer‘s Specifications:

- Consult the manufacturer‘s guidelines: Follow the manufacturer‘s recommendations for specific applications.

9. Safety Factor:

- Consider a safety factor: Select a hose with a pressure rating that exceeds the expected maximum pressure to account for potential pressure spikes or surges.

By carefully considering these factors and consulting with a hydraulic hose specialist, you can select the right hose for your specific application, ensuring optimal performance and safety.

Additional Considerations:

- Safety Factor: Many manufacturers incorporate a safety factor into their pressure ratings, which means the hose can withstand pressures higher than its rated working pressure.

- Fittings: The fittings used with the hose must also be rated for the same pressure as the hose itself.

- Installation and Maintenance: Proper installation and regular maintenance are essential to ensure the longevity and performance of hydraulic hoses.

By carefully considering these factors and consulting with a knowledgeable supplier, you can select the right hydraulic hose to meet your specific needs.

Conclusion

Hydraulic hose pressure rating is a critical factor to consider when selecting a hose for your specific application. Understanding the maximum working pressure and burst pressure of a hose ensures safe and efficient operation of your hydraulic system. By carefully considering these factors and consulting with a knowledgeable supplier, you can select the right hydraulic hose to meet your needs.

Ready to source high-quality, durable hydraulic hoses at competitive wholesale prices? Contact our experienced team at [Your Company Name] today. We offer a wide range of hydraulic hoses to suit various applications, backed by our commitment to quality and customer satisfaction.

Let us help you find the perfect hydraulic hose solution for your business.