Hydraulic hoses are essential components in fluid power systems, responsible for safely transmitting hydraulic fluid under pressure. Understanding hose specifications is crucial for selecting the right hose for your application. One important designation you may encounter is “TE,” which provides insight into hose construction and performance characteristics.

The term “TE” in hydraulic hoses refers to specific testing or reinforcement standards that ensure the hose can handle certain pressures and operational conditions. By understanding what “TE” signifies, users can select hoses that provide reliable performance, prevent leaks, and ensure long-term safety in industrial, construction, and mobile hydraulic systems.

What is “TE” in Hydraulic Hoses?

“TE” in hydraulic hoses stands for “Thermoplastic Elastomer” or indicates a specific testing/reinforcement standard, depending on the manufacturer.

It signifies that the hose meets certain pressure, temperature, and performance requirements, ensuring durability, flexibility, and reliable fluid transmission. Understanding “TE” helps users select hoses suited for industrial, construction, and mobile hydraulic applications.

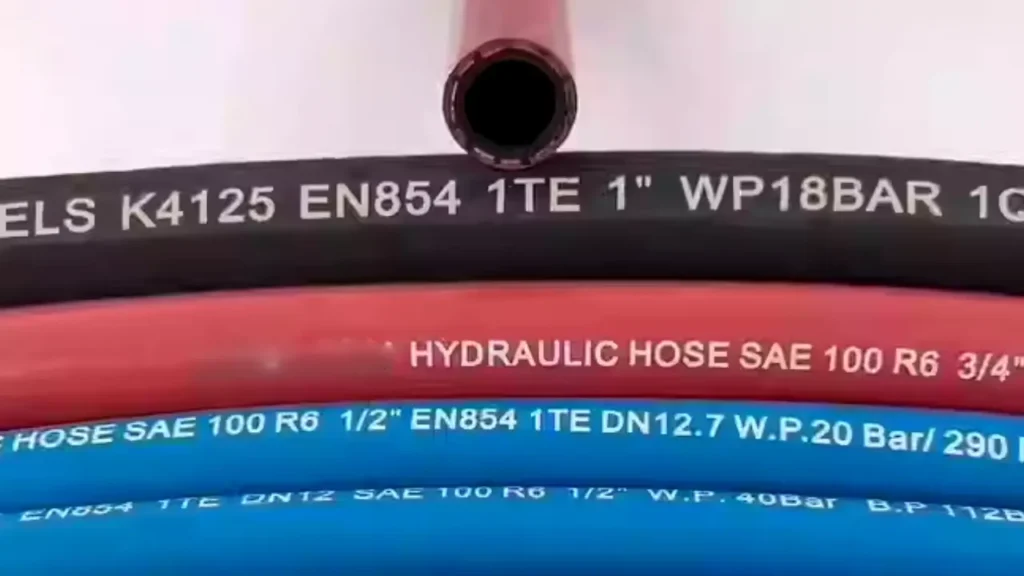

1TE refers to a single-wire braided or reinforced hose that meets specific ISO or hydraulic hose manufacturer standards. The “1” indicates one layer of steel wire reinforcement, while “TE” denotes thermoplastic elastomer or a particular testing/reinforcement standard. These hydraulic hoses are designed for medium-pressure hydraulic applications, offering flexibility, durability, and reliable fluid transmission.

Types of TE Hydraulic Hoses

TE hydraulic hoses are specialized hoses designed to meet certain pressure, temperature, and reinforcement standards. Understanding the types of TE hoses helps users select the right hose for reliable, safe, and efficient hydraulic system operation across industrial, construction, and mobile applications.

- 1TE Hydraulic Hoses: Single-wire braided hoses designed for medium-pressure applications. They provide flexibility, durability, and reliable fluid transmission, making them suitable for construction, agricultural, and light industrial hydraulic systems.

- 2TE Hydraulic Hoses: Double-wire braided hoses for higher-pressure systems. The additional reinforcement layer improves burst resistance, impulse performance, and durability, ensuring safe and efficient operation in demanding hydraulic environments.

- 4TE Hydraulic Hoses: Four-wire reinforced hoses ideal for high-pressure industrial and mobile hydraulic systems. They offer enhanced strength, fatigue resistance, and long service life, supporting continuous operation under extreme conditions.

- 6TE Hydraulic Hoses: Six-wire spiral or braided hoses designed for ultra-high pressure applications. They deliver maximum durability, impulse resistance, and performance reliability in heavy machinery, mining, and construction hydraulic systems.

- Spiral TE Hoses: Multi-wire spiral hoses for extreme pressure and heavy-duty applications. They combine flexibility with superior strength and burst resistance, making them suitable for mining, oil, and large industrial hydraulic operations.

TE Hydraulic Hose Benefits

TE hydraulic hoses provide reliable performance, safety, and durability in medium to ultra-high pressure hydraulic systems. Their reinforced design and thermoplastic elastomer construction ensure consistent fluid transmission, flexibility, and resistance to wear, making them ideal for construction, industrial, agricultural, and mobile hydraulic applications.

- High-pressure handling: TE hoses are designed to withstand medium to ultra-high pressures, preventing leaks and bursts. Reinforced layers ensure stable fluid transmission, protecting hydraulic systems from failure under demanding conditions.

- Durability and long service life: Reinforced construction resists abrasion, crushing, and environmental wear. This durability extends hose lifespan, reduces maintenance frequency, and ensures continuous, reliable performance in various industrial and mobile hydraulic applications.

- Flexibility and ease of installation: TE hoses maintain flexibility even under pressure and temperature extremes. Their design allows for smooth routing in tight spaces, reducing installation stress and ensuring efficient system operation.

- Chemical and temperature resistance: Constructed from thermoplastic elastomer or compatible materials, TE hydraulic hoses resist oils, chemicals, and temperature variations. This ensures safe, reliable operation across diverse industrial, construction, and mobile environments.

- Versatile applications: Suitable for hydraulic machinery, construction equipment, and mobile systems, TE hydraulic hoses provide consistent performance, reliability, and safety, making them ideal for a wide range of demanding hydraulic applications.

Why Choose Our Hydraulic Hoses?

Choosing the right hydraulic hose is critical for system safety, efficiency, and durability. Our hoses meet international standards, offering reliable performance, long service life, and superior resistance to pressure, abrasion, and environmental factors. They are suitable for construction, industrial, agricultural, and mobile hydraulic applications.

- ISO and TE standard compliance: We manufacture hoses that meet ISO and TE specifications, ensuring consistent performance, safety, and reliability. Compliance guarantees compatibility with global hydraulic systems and reduces the risk of leaks or failures under demanding operating conditions.

- Durable materials: Our hoses use high-quality rubber, thermoplastic elastomer, and reinforced layers to resist wear, abrasion, oil, and extreme temperatures. This ensures long-lasting performance, minimal maintenance, and reliable operation in harsh environments.

- Versatile fittings and assemblies: We provide hoses with secure, standardized fittings compatible with various hydraulic systems. Properly designed assemblies reduce leaks, ensure safe installation, and maintain efficient fluid transmission under high-pressure conditions.

- Wide range of applications: Our hoses are suitable for construction equipment, industrial machinery, agricultural systems, and mobile hydraulics. They deliver reliable performance across multiple industries, ensuring safety, efficiency, and consistent hydraulic operation.

- Tested for performance: Every hose undergoes rigorous testing for pressure, bending, and impulse resistance. This ensures each product maintains consistent quality, reliability, and durability, providing peace of mind for demanding hydraulic applications.

Conclusion

Understanding “TE” in hydraulic hoses helps you make informed decisions when selecting hoses for high-pressure applications. It ensures your hydraulic system operates safely and efficiently while meeting required performance standards. Choosing hoses with the correct “TE” rating prevents system failures and costly downtime.

Selecting the right hydraulic hose with the proper “TE” designation guarantees durability, reliability, and consistent performance under demanding conditions. This knowledge is essential for industries such as construction, mining, manufacturing, and mobile hydraulics where safety and efficiency are top priorities.

For quality and wholesale hydraulic hoses, get them from Gushan Rubber. We offer a wide range of hoses meeting ISO and TE standards, ensuring optimal performance, durability, and safety for all your hydraulic systems. Our bulk supply solutions support industrial and commercial needs efficiently.